Injection type refrigerating machine with middle heat exchanging part

An intermediate heat exchange and injection technology, which is used in refrigerators, machines using refrigerant evaporation, refrigeration and liquefaction, etc., can solve the problems of complex structure and high operating costs, and achieve the effect of improving the cooling coefficient and reducing the load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

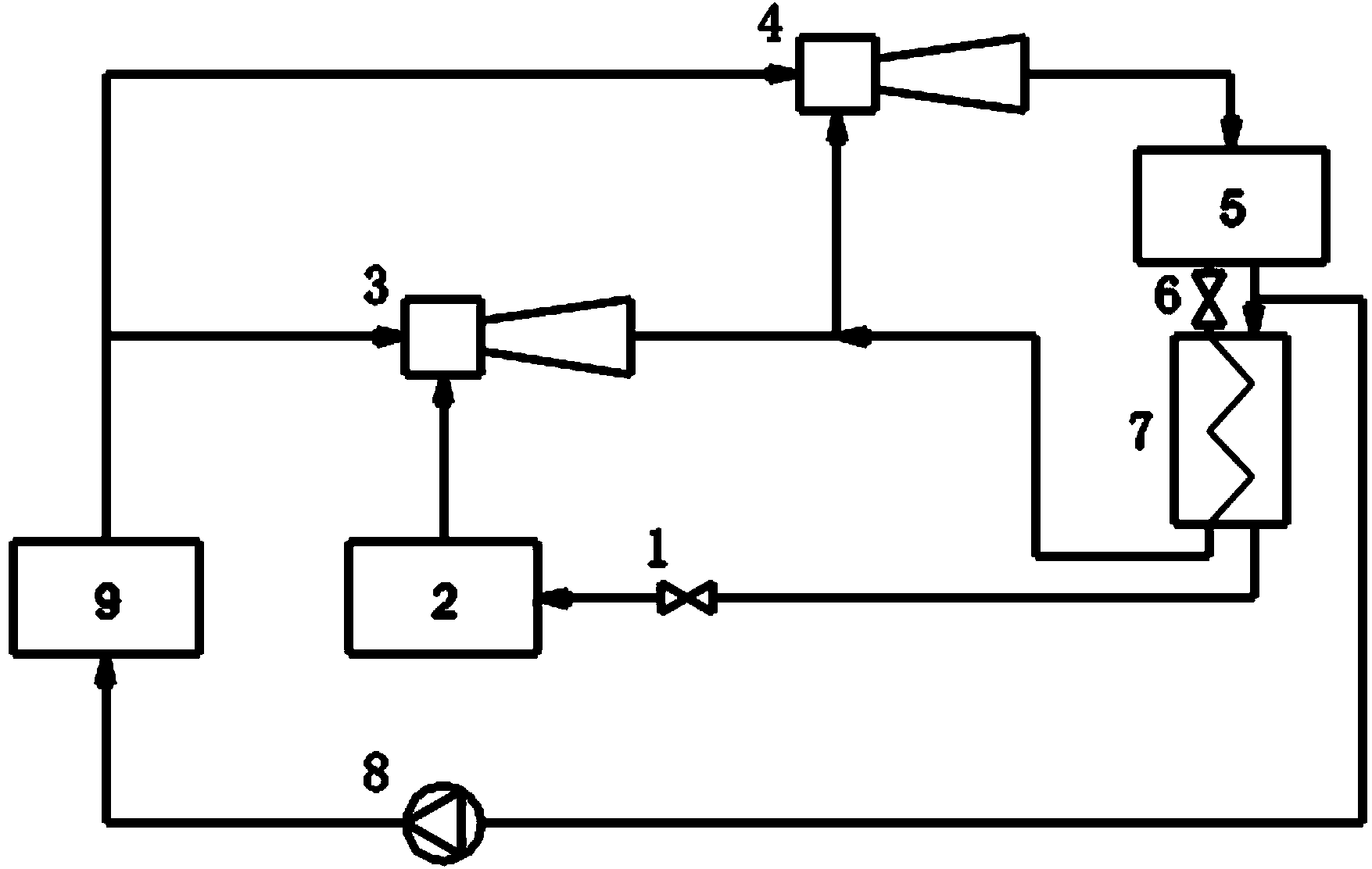

[0029] Such as figure 1 As shown, an ejector refrigerator with intermediate heat exchange components includes a first throttling element 1, an evaporator 2, a first ejector 3, a second ejector 4, a condenser 5, and a second throttling element 6 , subcooler 7, circulation pump 8, first generator 9.

[0030] The working fluid inlets of the first injector 3 and the second injector 4 and the working fluid outlet of the first generator 9 (in the present invention, "working fluid outlet" and "exit" all represent the same concept unless otherwise specified. ) communication, the injection fluid inlet of the first injector 3 is connected with the working medium outlet of the evaporator 2, the working medium outlet of the first injector 3 is connected with the injection fluid inlet of the second injector 4, and the second injection The working medium outlet of the condenser 4 is connected with the working medium inlet of the condenser 5; between the working medium outlet of the condens...

Embodiment 2

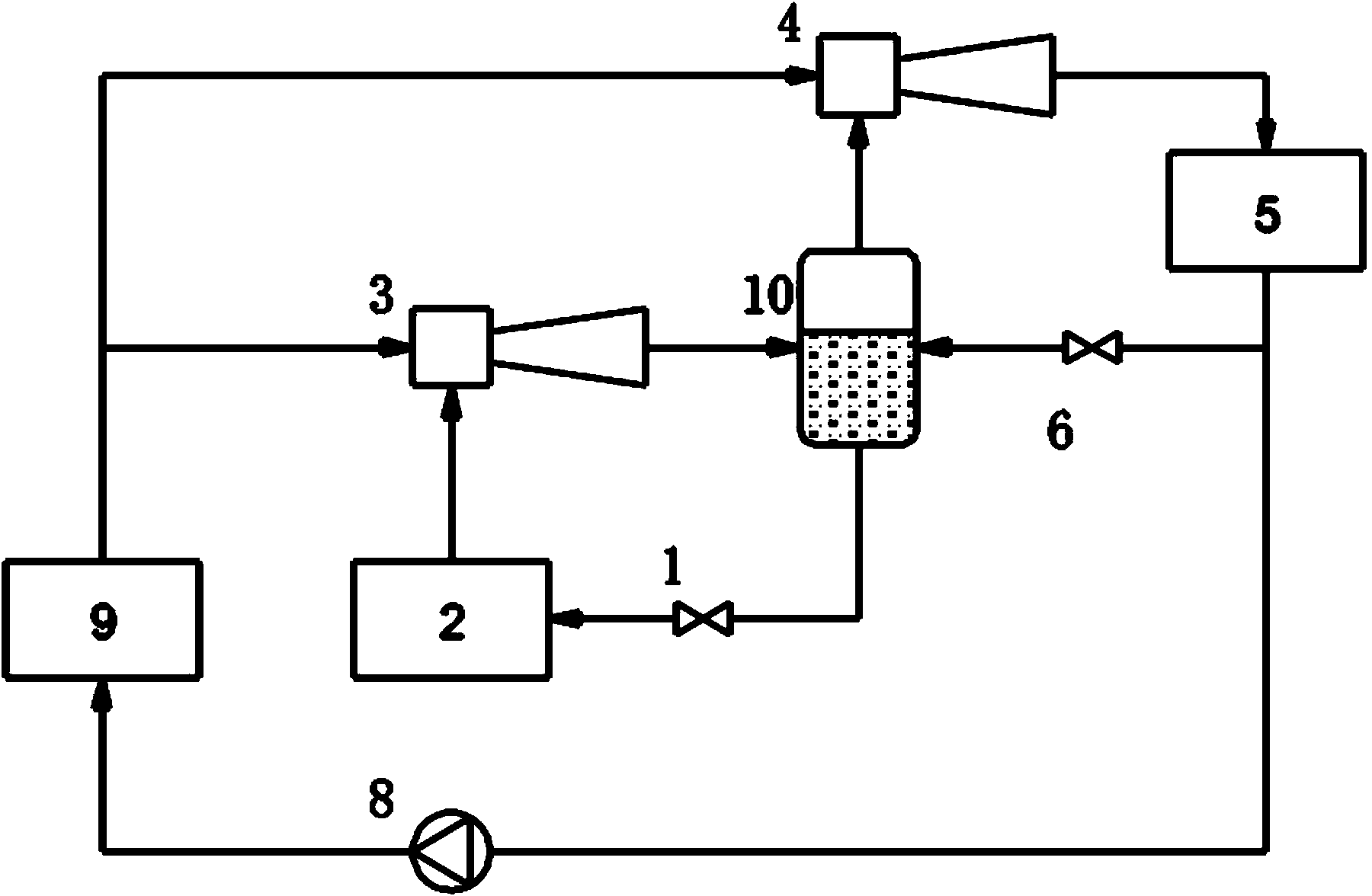

[0034] Such as figure 2 As shown, an ejector refrigerator with intermediate heat exchange components includes a first throttling element 1, an evaporator 2, a first ejector 3, a second ejector 4, a condenser 5, and a second throttling element 6 , Economizer 10, circulation pump 8, first generator 9.

[0035] The gas-phase working medium outlet of the economizer 10 is connected with the injection fluid inlet of the second injector 4; the working medium outlet of the first injector 3, the working medium outlet of the second throttling element 6 and the working medium inlet of the economizer 10 The liquid-phase working medium outlet of the economizer 10 is connected with the working medium inlet of the first throttling element 1; at this time, a part of the working medium liquid at the outlet of the condenser 5 is throttled by the second throttling element 6 and becomes an intermediate pressure The lower two-phase state is mixed with the working fluid at the outlet of the first...

Embodiment 3

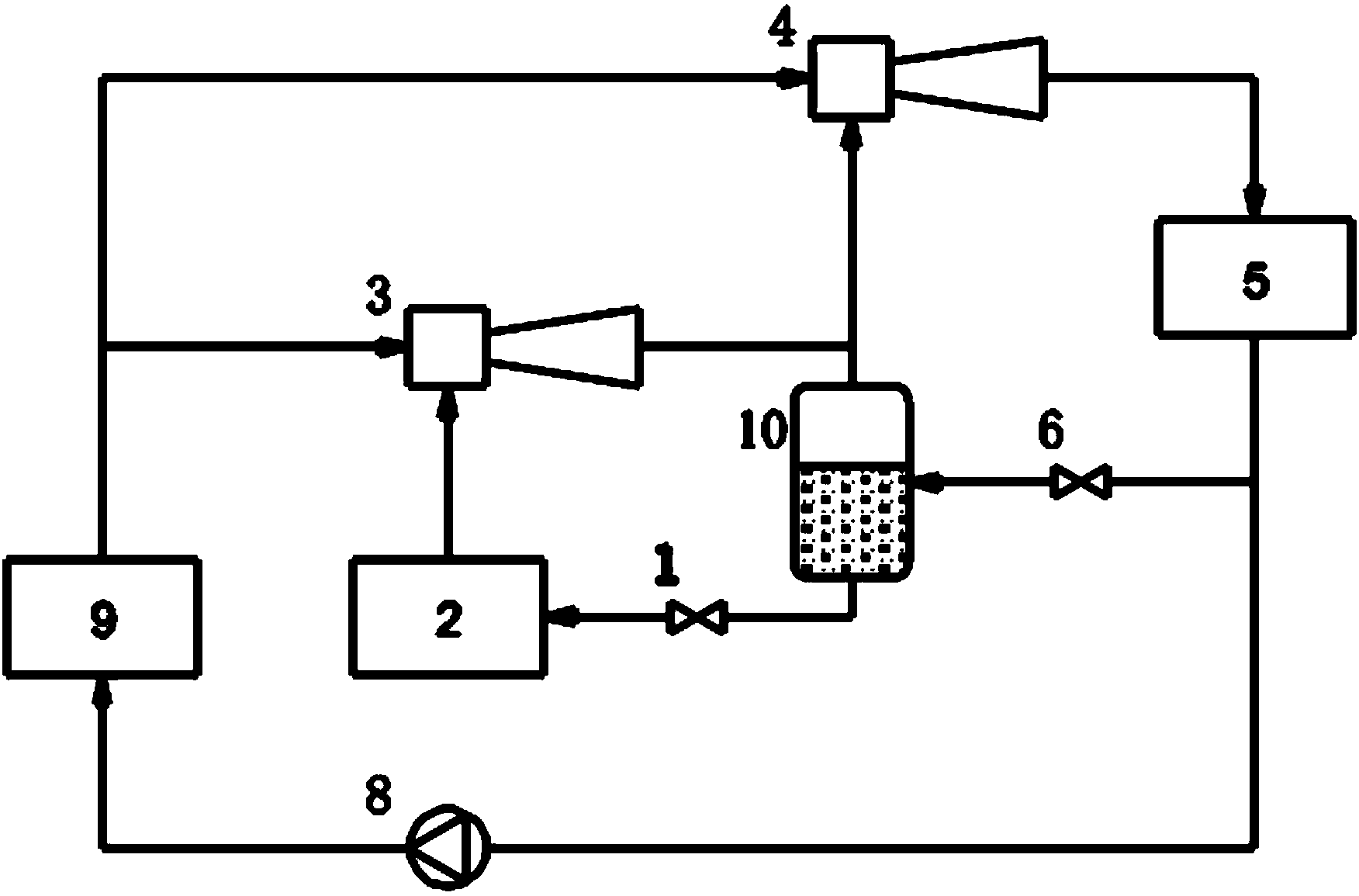

[0037] Such as image 3 As shown, an ejector refrigerator with intermediate heat exchange components includes a first throttling element 1, an evaporator 2, a first ejector 3, a second ejector 4, a condenser 5, and a second throttling element 6 , Economizer 10, circulation pump 8, first generator 9.

[0038] The gas-phase working medium outlet of the economizer 10 is connected with the injection fluid inlet of the second injector 4; the working medium outlet of the second throttling element 6 is connected with the working medium inlet of the economizer 10; the liquid-phase working medium of the economizer 10 The outlet of the refrigerant is connected with the inlet of the working fluid of the first throttling element 1; at this time, a part of the working fluid at the outlet of the condenser 5 is throttled by the second throttling element 6 and becomes a two-phase state under intermediate pressure. 10 is divided into two phases of gas and liquid, the gas phase working medium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com