Detection reagents and method for detecting iron ores by X fluorescent spectrometry

A fluorescence spectrometry and detection reagent technology, applied in the field of steelmaking industry, can solve problems such as high cost, poor linearity of production working curve, erosion of platinum yellow crucible, etc., and achieve the effects of reducing detection cost, improving accuracy and prolonging service time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

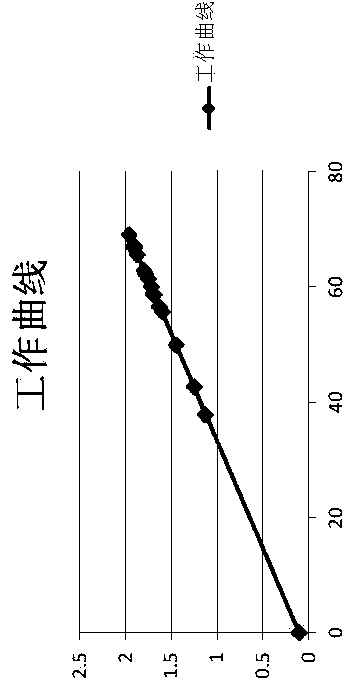

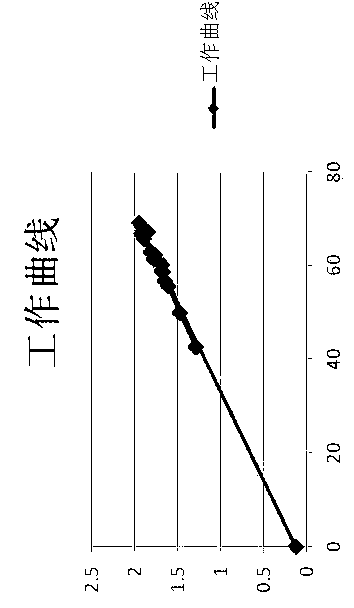

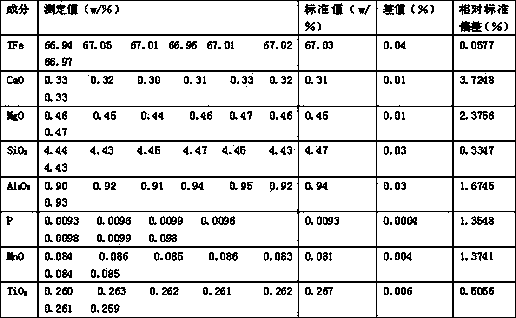

Image

Examples

Embodiment Construction

[0016] The present invention prepares internal standard cobalt powder: take anhydrous lithium tetraborate-lithium metaborate mixed flux, dicobalt trioxide and mix in a beaker, place in a Pt-Au crucible, add lithium nitrate and lithium bromide, put into a high-frequency melting pot The sample furnace is melted at a temperature of 1100°C: the first heating time is 3 minutes, the temperature is 600°C; the second heating time is 3 minutes, the temperature is 1100°C; the melting time is 4 minutes, the temperature is 1100°C; Take out the vibration grinding sample in the vibrating mill for 2 minutes, bottle it and put it in a desiccator for later use;

[0017] Lithium tetraborate-lithium metaborate ∶ Cobalt trioxide ∶ lithium nitrate ∶ Lithium bromide=15 ∶ 1 ∶ 0.6 ∶ 0.4;

[0018] Preparation of glass frits: Take the burned and cooled anhydrous lithium tetraborate-lithium metaborate mixed flux, sample, internal standard cobalt powder, lithium nitrate, and lithium bromide in a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com