Method for testing magnesium oxide in talcum powder

A method of determination, talcum powder technology, applied in the direction of chemical analysis by titration method, etc., can solve the problems of difficult to obtain, expensive platinum, etc., and achieve the effect of easy operation

Inactive Publication Date: 2014-01-22

HUBEI FORBON TECH

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] (2) Use a platinum crucible to melt talc powder. This is because the chemical properties of platinum are stable and can withstand molten alkali metal carbonate, which has no effect on the determination of magnesium oxide. However, platinum is expensive and difficult to detect under general laboratory conditions. obtained, which limits its use to some extent

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

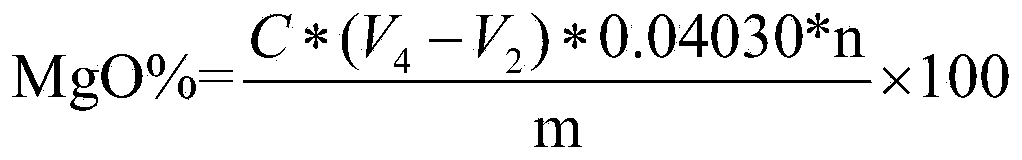

[0021] Example: a method for the determination of magnesium oxide in talcum powder, the triethanolamine solution used is a mixture of triethanolamine and water at a volume ratio of 1:2.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

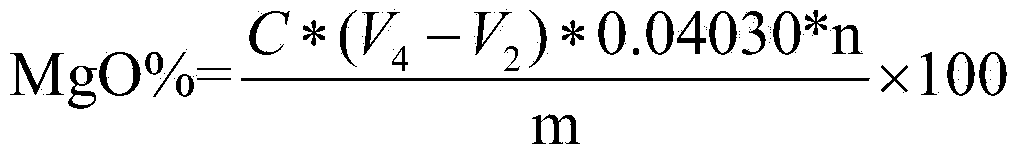

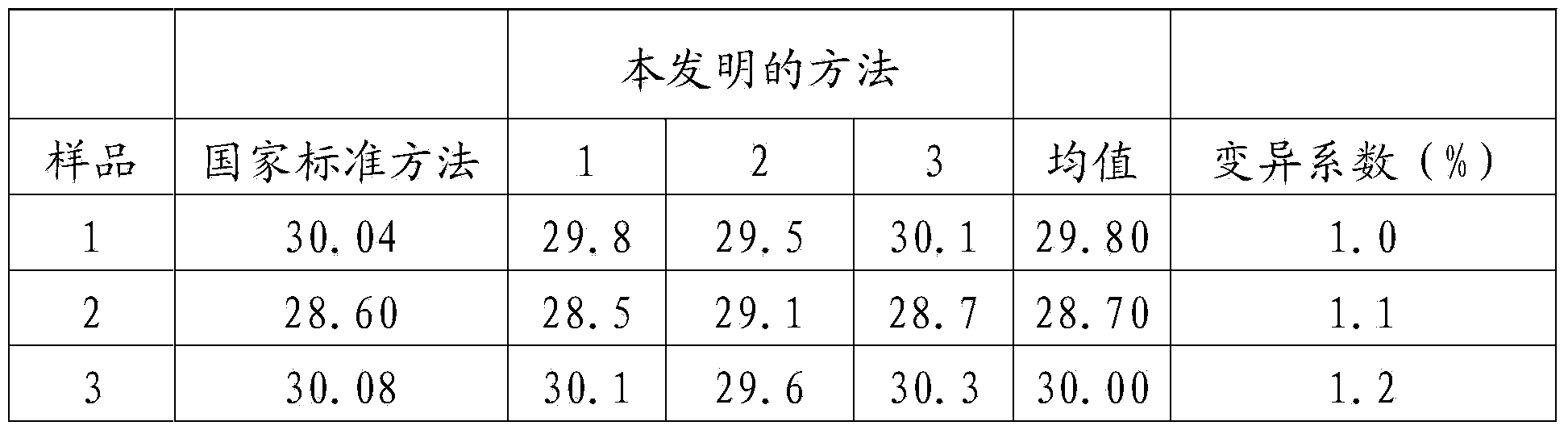

The invention relates to a method for testing magnesium oxide in talcum powder. The method specifically comprises the following steps: putting a certain amount of the talcum powder into a nickel crucible, adding a corresponding amount of solid NaOH, smelting in a muffle furnace of 700-750 DEG C, acidizing through hydrochloric acid and performing complexometric titration through an ethylene diamine tetraacetic acid (EDTA) standard solution. In the titration process, interference of Fe ions, Al ions and Ni ions as the nickel crucible is used can be prevented by taking a triethanolamine solution together with phenanthroline as a masking agent. The method is simple and convenient to operate, accurate in testing result and both economical and time-saving.

Description

technical field [0001] The invention relates to a method for determining magnesium oxide components in talc powder. Background technique [0002] Talc powder is a very important raw material, its main component is hydrated magnesium silicate, the molecular formula is Mg 3 [Si 4 o 10 ](OH) 2 . Therefore, the content of silicon dioxide and magnesium oxide are two important indicators for evaluating talc powder. At present, the literature shows that the determination method of silicon dioxide has been reported, but there is only a national standard method for the determination of magnesium oxide. The national standard method has the following deficiencies: [0003] (1) The melting process of talcum powder is cumbersome and complicated, which is time-consuming and prone to errors during the operation, which reduces the accuracy of the measurement results. [0004] (2) Use a platinum crucible to melt talc powder. This is because the chemical properties of platinum are stab...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N31/16

Inventor 蔚霞王仁宗王瑞

Owner HUBEI FORBON TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com