Automatic seedling-guiding no-tillage seeding transplanting machine

An automatic technology for seedling cultivation and transplanting, which is applied in the field of agricultural machinery, can solve problems such as high cost, complex structure, and reduced crop yield, and achieve the effects of improved work efficiency, good adaptability, and good soil penetration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

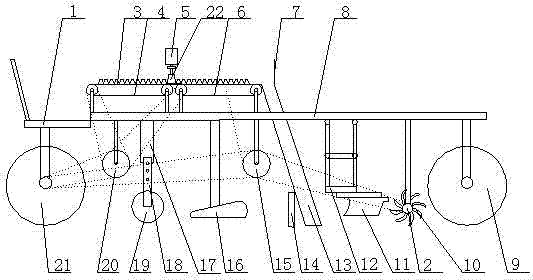

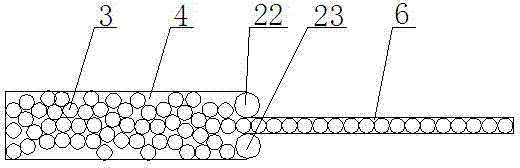

[0013] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0014] As can be seen from the accompanying drawings, a kind of no-tillage seedling transplanting machine capable of automatically guiding seedlings of this program includes a frame 8, and one end of the frame 8 is a ground wheel 21 that provides power for the whole transplanting machine, and the frame 8 The other end of the frame is a walking wheel 9; the bottom of the frame 8 is connected with a ditching mechanism and a soil compacting mechanism. The ditching mechanism includes a core type ditch opener 11, and the frame 8 is provided with a groove for controlling the depth of the ditch and the angle of entry into the soil. The parallel four-bar linkage profiling mechanism 12, the rigid connecting rod lower end of the parallel four-bar linkage profiling mechanism 12 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com