Using method of crop straw crusher

A crop straw and pulverizer technology, applied in the field of breeding feed, can solve the problems of easily hurting its fingers, not easy to cut off, accidents, etc., achieve good crushing effect, easy crushing, and reduce the incidence of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

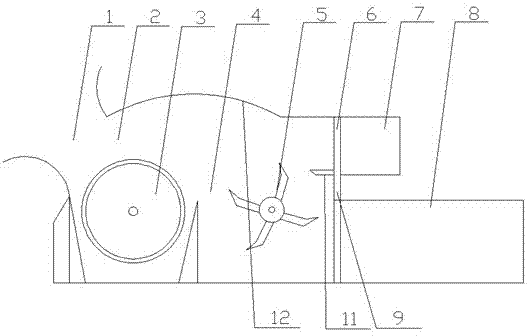

[0026] The present invention will be described below in conjunction with the accompanying drawings.

[0027] A method for using a crop straw grinder, which includes the following steps:

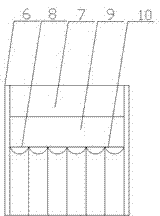

[0028] A. The step of feeding: put the young crop straw on the feeding table, press the young crop straw, so that the young crop straw is located in each feeding trough;

[0029] B. The step of external pressing: pull down the pressing table so that the pressing table is pressed on the young crop stalks to feed;

[0030] C. Steps of internal pressing: the young crop straw extends into the cutting chamber along the feeding port, and the top of the young crop straw is blocked by the cutting baffle,

[0031] D. Cutting steps: Gently push the green crop stalks, the green crop straws enter the cutting chamber along the flat rectangular feeding port, and are cut into small sections of 3-5cm by the reamer in the cutting chamber; at the same time, due to the centrifugal force of the reamer rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com