High Strength Incense

A kind of incense stick, high-strength technology, applied in the field of incense stick manufacturing, can solve the problems of easy breakage, poor toughness, etc., and achieve the effects of strength change, good flammability, and easy transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

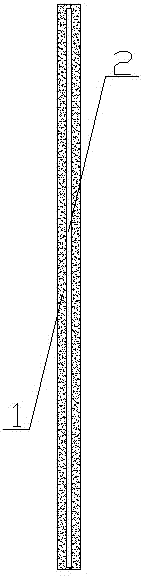

[0009] Embodiment 1: with reference to attached figure 1 . A high-strength incense stick, comprising incense sticks 1 wrapped on incense sticks 2 . The incense core strip 2 is located at the center of the incense stick 1 and the length of the incense core strip 2 is slightly smaller than the length of the incense stick 1 . The incense sticks 2 are bamboo sticks. The incense stick 1 and the incense core strip 2 are extruded and bonded. The surface of the incense stick 1 is flat and smooth.

Embodiment 2

[0010] Embodiment 2: On the basis of Embodiment 1, the incense stick 2 is a bamboo fiber stick, and the production of the fiber stick is a prior art, so it will not be described here.

Embodiment 3

[0011] Embodiment 3: On the basis of Example 1, the surface of the incense stick 2 is a concave-convex rough surface. The sticky material in the fragrance group can form a good bonding effect, and can also promote the molecules in the natural compound fragrance group to penetrate into the incense stick, so as to achieve an organic and reliable combination, effectively improving the peeling between the incense stick and the incense stick strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com