Toothpaste and preparation method thereof

A toothpaste and paste technology, which is applied in the field of daily necessities, can solve problems such as failure to protect teeth, and achieve the effect of improving periodontal health and nourishing gum and periodontal health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

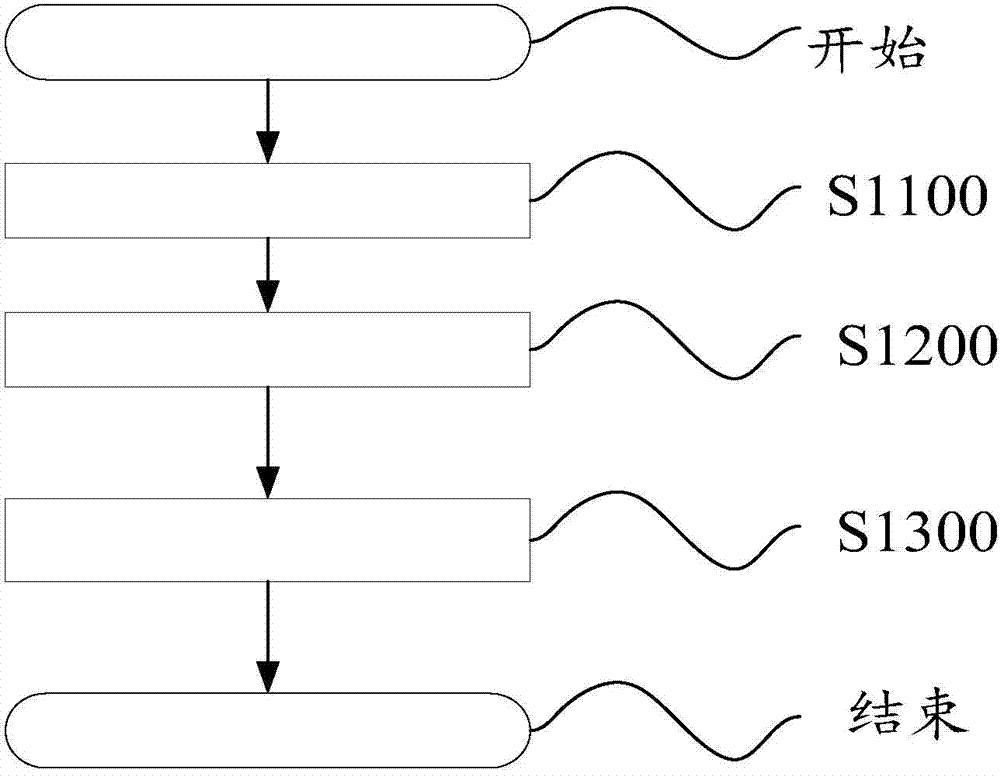

[0024] According to the preparation method of the toothpaste of the present invention, the raw materials required by the method include by weight: 0.1 to 0.5 parts of bear bile powder, 15 to 25 parts of sorbitol, 5 to 10 parts of glycerin, 20 to 30 parts of calcium hydrogen phosphate dihydrate, 10-22 parts of hydrated silica, 5-15 parts of xylitol, 2-2.6 parts of sodium lauryl sulfate, 0.5-1.2 parts of cellulose gum, 0.3-0.7 parts of xanthan gum, 0.1-0.3 parts of sodium benzoate, 0.2 parts ~0.3 part of sodium saccharin, 0.2~0.3 part of anhydrous coke sodium, 1~1.5 parts of essence, add water to 100 parts, wherein, the preparation method includes the following steps: first enter the batching step S1100: add the raw materials into water; then enter Stirring step S1200: Stir the ingredients for 20-30 minutes to obtain a paste; finally enter the degassing step S1300: stir and degas the paste for 20-30 minutes to obtain toothpaste. Step S1300 is now completed, and the preparation of...

Embodiment 1

[0030] according to figure 1 The preparation method of a kind of toothpaste of the present invention shown, the raw material that this method needs comprises by weight: 0.1 part of bear bile powder, 15 parts of sorbitol, 5 parts of glycerin, 20 parts of calcium hydrogen phosphate dihydrate, 10 parts of hydrated silica , 5 parts of xylitol, 2 parts of sodium lauryl sulfate, 0.5 parts of cellulose gum, 0.3 parts of xanthan gum, 0.1 parts of sodium benzoate, 0.2 parts of sodium saccharin, 0.2 parts of anhydrous coke sodium, 1 part of essence, add water to 100 parts, wherein, the preparation method includes the following steps: batching step S1100: adding the raw materials into water, first dissolving the bear bile powder, the sodium saccharin and the anhydrous coke sodium in water; then dissolving the Add the sorbitol and the glycerin into the bear bile powder solution and mix uniformly; finally add the dibasic calcium phosphate dihydrate, the hydrated silica, the xylitol, the so...

Embodiment 2

[0032] according to figure 1The preparation method of a kind of toothpaste of the present invention shown, the raw material that this method needs comprises by weight: 0.5 part of bear bile powder, 25 parts of sorbitol, 10 parts of glycerin, 30 parts of calcium hydrogen phosphate dihydrate, 22 parts of hydrated silica , 15 parts of xylitol, 2.6 parts of sodium lauryl sulfate, 1.2 parts of cellulose gum, 0.7 parts of xanthan gum, 0.3 parts of sodium benzoate, 0.3 parts of sodium saccharin, 0.3 parts of anhydrous sodium coke, 1.5 parts of essence, add water to 100 parts, wherein, the preparation method includes the following steps: batching step S1100: adding the raw materials into water, first dissolving the bear bile powder, the sodium saccharin and the anhydrous coke sodium in water; then dissolving the Add the sorbitol and the glycerin into the bear bile powder solution and mix uniformly; finally add the dibasic calcium phosphate dihydrate, the hydrated silica, the xylitol, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com