Preparation method of cobalt molybdate microcrystals

A technology of cobalt molybdate and microcrystals, applied in chemical instruments and methods, cobalt compounds, inorganic chemistry, etc., can solve the problems of uncontrollable microscopic appearance, high impurity content of products, high reaction equipment conditions, etc., and meet the requirements and products High yield and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

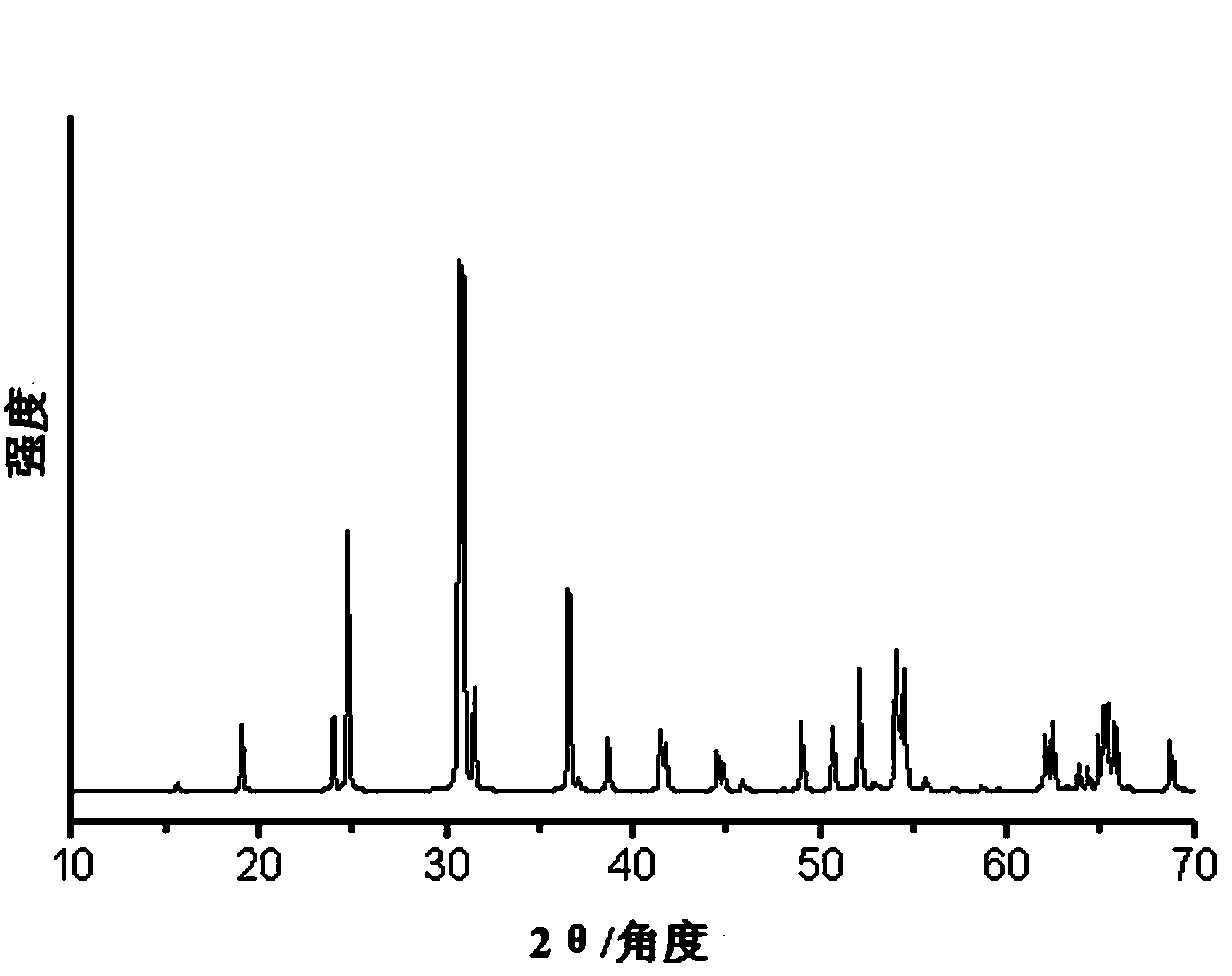

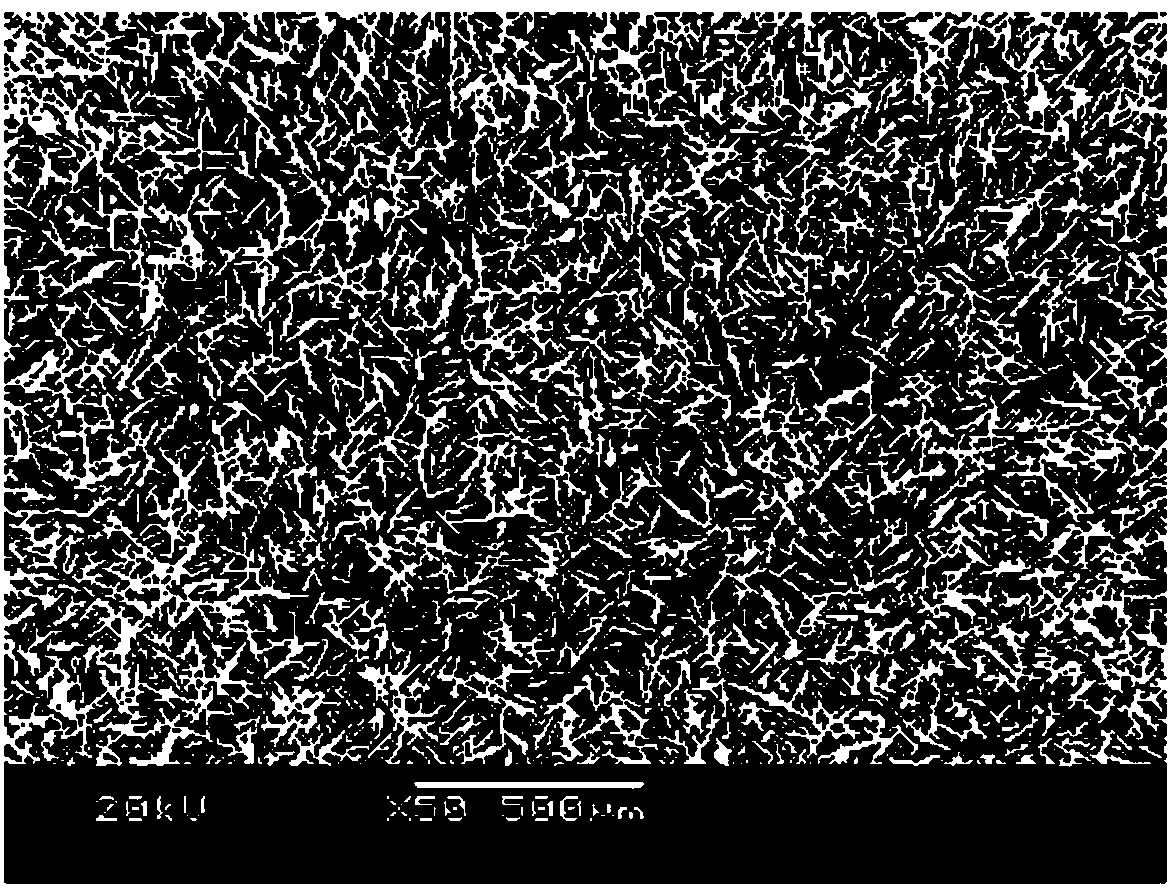

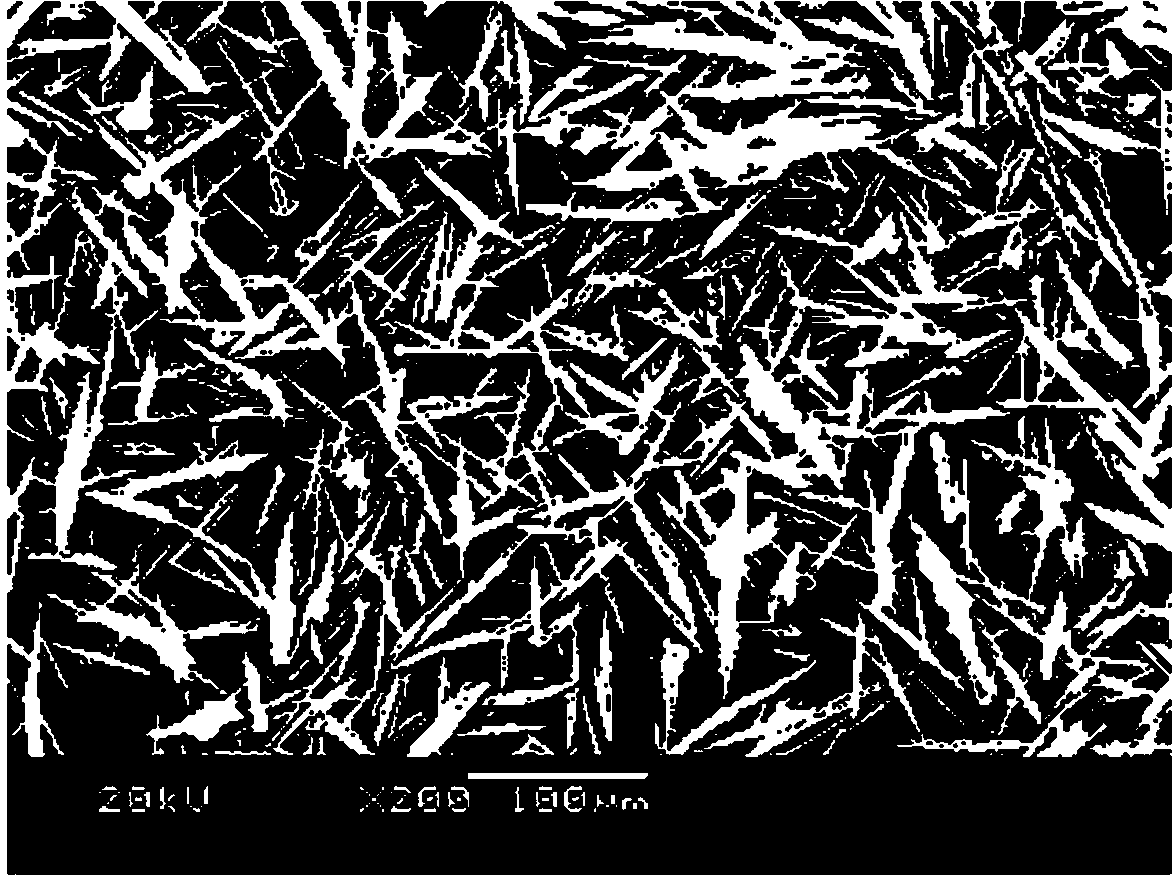

Embodiment 1

[0026] Slowly add the 0.1 mol / L cobalt nitrate solution dropwise to the 0.1 mol / L sodium molybdate solution at room temperature. The amount of the mixed solution added is based on the molar ratio of cobalt nitrate / sodium molybdate = 1:1, and the reaction is stirred and reacted at a stirring speed of 70 rpm for 20 minutes. The obtained mixed solution was subjected to hydrothermal reaction, the hydrothermal reaction temperature was 200° C., and the hydrothermal reaction time was 24 hours. After the hydrothermal reaction, cool down to room temperature naturally, filter and wash the product obtained by the reaction, put it in an oven, and dry it for 15 hours at 150 °C to obtain a cobalt molybdate microcrystalline product, which has the shape of a micron rod. The diameter is between 1 and 5 μm, and the length is between 50 and 100 μm.

Embodiment 2

[0028] Slowly add the 0.2 mol / L cobalt nitrate solution dropwise to the 0.2 mol / L sodium molybdate solution at room temperature. The amount of the mixed solution added is based on the molar ratio of cobalt nitrate / sodium molybdate = 1:1, and the reaction is stirred and reacted at a stirring speed of 70 rpm for 20 minutes. The obtained mixed solution was subjected to hydrothermal reaction, the hydrothermal reaction temperature was 200° C., and the hydrothermal reaction time was 24 hours. After the hydrothermal reaction, cool down to room temperature naturally, filter and wash the product obtained by the reaction, put it in an oven, and dry it for 15 hours at 180 °C to obtain a microcrystalline product of cobalt molybdate, which has the shape of a micron rod. The diameter is between 1 and 3 μm, and the length is between 50 and 90 μm.

Embodiment 3

[0030] Slowly add the 0.1 mol / L cobalt acetate solution dropwise to the 0.1 mol / L sodium molybdate solution at room temperature. The amount of the mixed solution added is based on the molar ratio of cobalt acetate / sodium molybdate = 1:1, and the reaction is stirred and reacted at a stirring speed of 70 rpm for 20 minutes. The obtained mixed solution was subjected to hydrothermal reaction, the hydrothermal reaction temperature was 180° C., and the hydrothermal reaction time was 24 hours. After the hydrothermal reaction, cool down to room temperature naturally, filter and wash the product obtained by the reaction, put it in an oven, and dry it for 15 hours at 180 °C to obtain a microcrystalline product of cobalt molybdate, which has the shape of a micron rod. The diameter is between 1 and 3 μm, and the length is between 50 and 80 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap