Resin lining steel molding plate for undevelopable cone curve face structure and manufacturing method thereof

A production method and technology of curved surface, applied in the field of construction, can solve the problems of inability to meet the construction requirements of fair-faced concrete, inability to ensure that the formwork is excessively smooth, and the difficulty of cutting the formwork panel, so as to improve the material utilization rate and the overall shape conformity. , The effect of improving the utilization rate of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings, but the implementation of the present invention is not limited thereto.

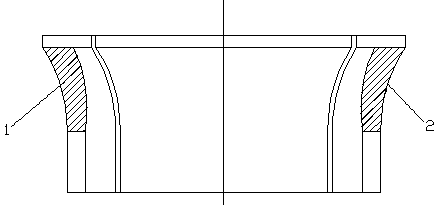

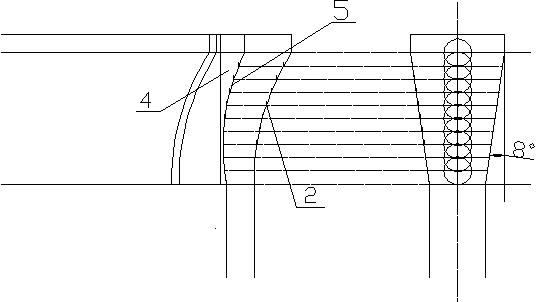

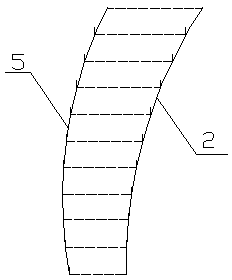

[0043] Such as Figure 9 As shown, the resin-lined steel formwork for structures with non-expandable conical surfaces provided by the present invention includes a steel frame 3 made by a conventional method, and a plurality of trapezoidal panels 6 are welded on the steel frame 3, and the trapezoidal panels 6 are connected with the steel frame 3 The surface connected with the arc surface is the reverse side of the trapezoidal panel, and the surface of the trapezoidal panel 6 in contact with the structure is the front side of the trapezoidal panel. A gap of 0-20 mm is formed between adjacent trapezoidal panels 6, and these gaps are sealed with adhesive tapes respectively. On the front of the trapezoidal panel 6 and the gap between the trapezoidal panels 6, an epoxy resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com