Biomass fuel burning equipment and burning method thereof

A biomass fuel and combustion equipment technology, applied in combustion methods, combustion equipment, solid fuel combustion and other directions, can solve the problems of inability to centralize cleaning, easy environmental pollution, high maintenance costs, and achieve the effects of convenient cleaning and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below through specific embodiments.

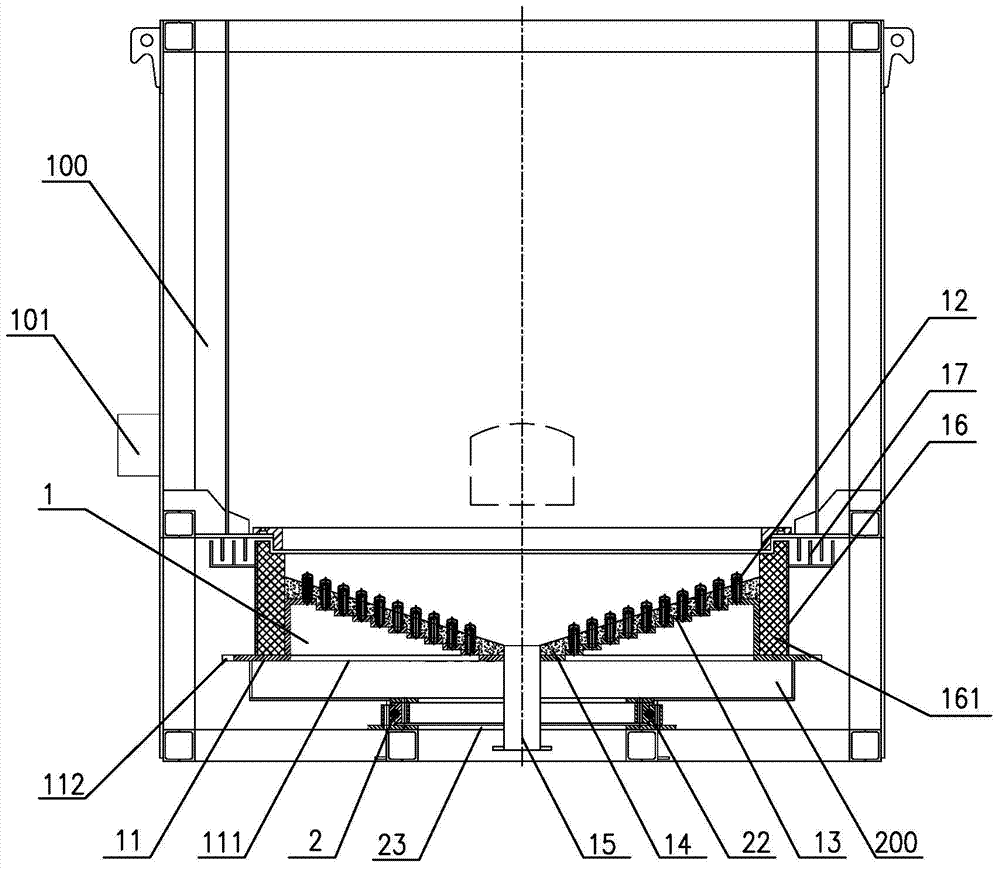

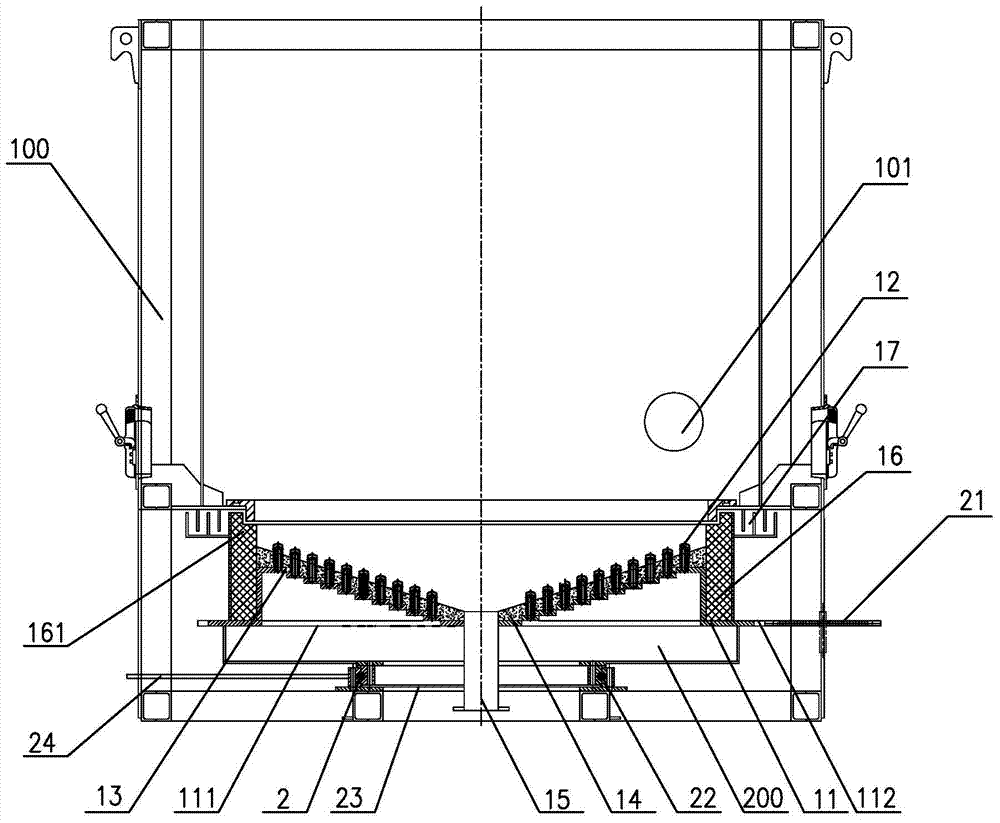

[0026] refer to Figure 1 to Figure 4 As shown, a biomass fuel combustion equipment is suitable for supporting boilers, water heaters and hot blast stoves, etc., including a combustion furnace 100 and an air supply device 200, and the combustion furnace 100 is provided with a rotatable fire grate 1 and the grate rotation driving device 2, the air supply device 200 communicates with the combustion furnace 100 and delivers high-pressure air to the bottom of the grate 1.

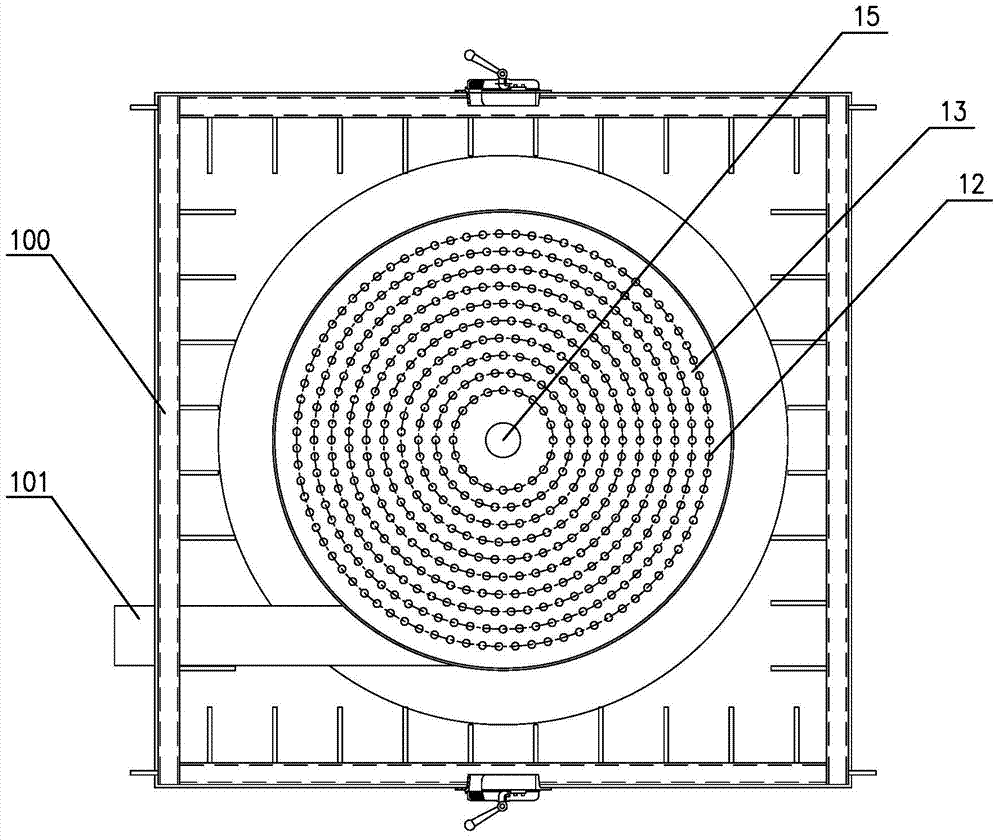

[0027] The grate 1 includes a rotating bottom plate 11, a plurality of hoods 12, a hood support plate 13, a refractory mud layer 14, an ash fall pipe 15, a sealing plate 16 and a sealing device 17;

[0028] The rotating bottom plate 11 is a circular structure with an air inlet 111 on its bottom and a ring gear 112 on its outer edge;

[0029] The air cap 12 is a circular tube structure with one end closed, and the tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com