Waste heat recovery management and control platform of large-scale alkaline water electrolysis hydrogen production device

A technology for hydrogen production device and waste heat recovery, applied in electrolysis components, electrolysis process, non-electric variable control, etc., can solve problems such as hidden dangers of hydrogen production operation, insufficient stability and accuracy of heat treatment, burning of electronic control equipment, etc., and achieve recovery adjustment. The control process is stable and accurate, the heat treatment efficiency is improved, and the control accuracy is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

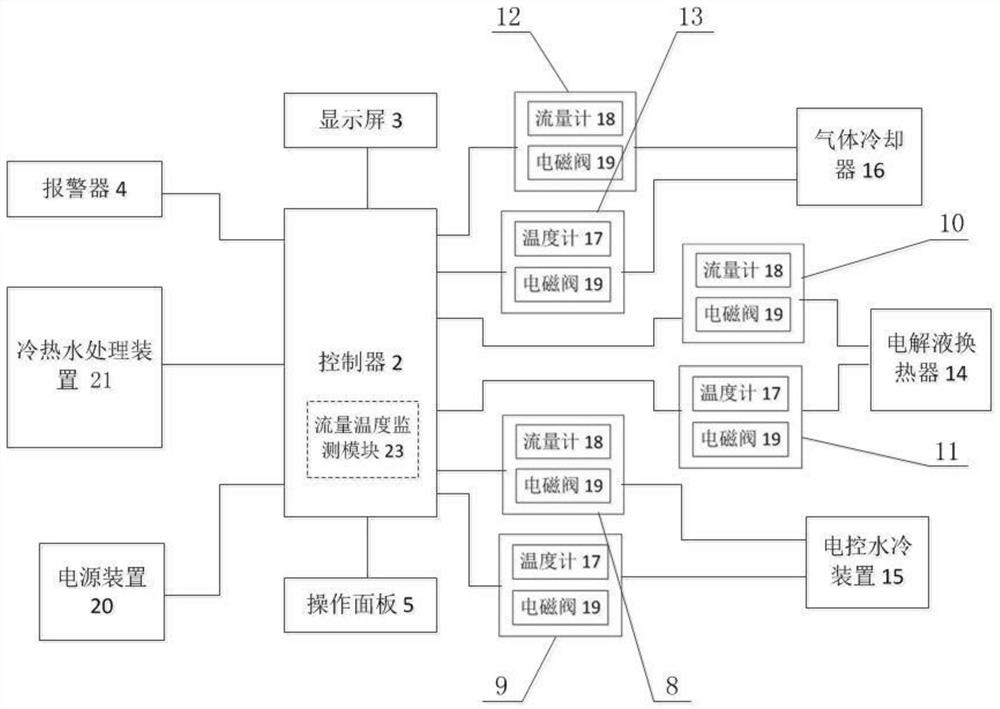

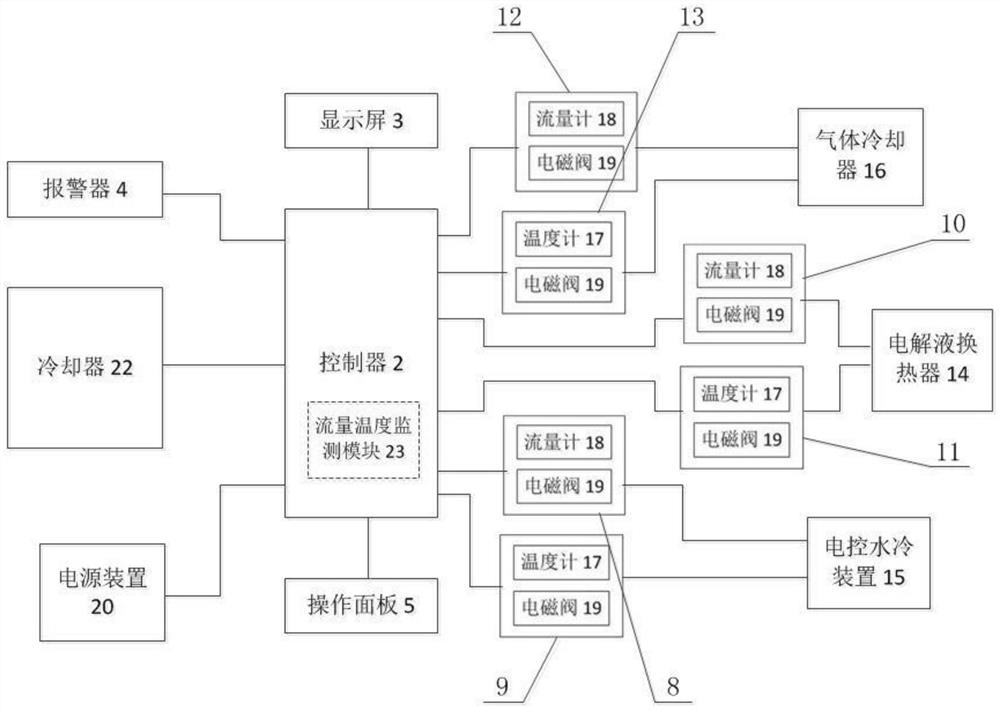

[0029] like figure 1 , figure 2 , Figure 4 , Figure 5 As shown, this embodiment provides a waste heat recovery management and control platform for a large-scale alkaline electrolyzed water hydrogen production device, including a platform body 1, a controller 2, a first cooling water supply port 8, a first hot water recovery port 9, a first Two cooling water supply ports 10, a second hot water recovery port 11, a third cooling water supply port 12, a third hot water recovery port 13, an electronically controlled water cooling device 15, an electrolyte heat exchanger 14, a gas cooler 16, and a power supply The device 20, the cold and hot water treatment device 21, in this embodiment, the platform body 1 provides an overall platform for the placement of each device, and the controller 2 is used as the control core, which can be a single-chip control system or a PLC control system. Programmable logic controller is the abbreviation of Programmable logic controller in English....

Embodiment 2

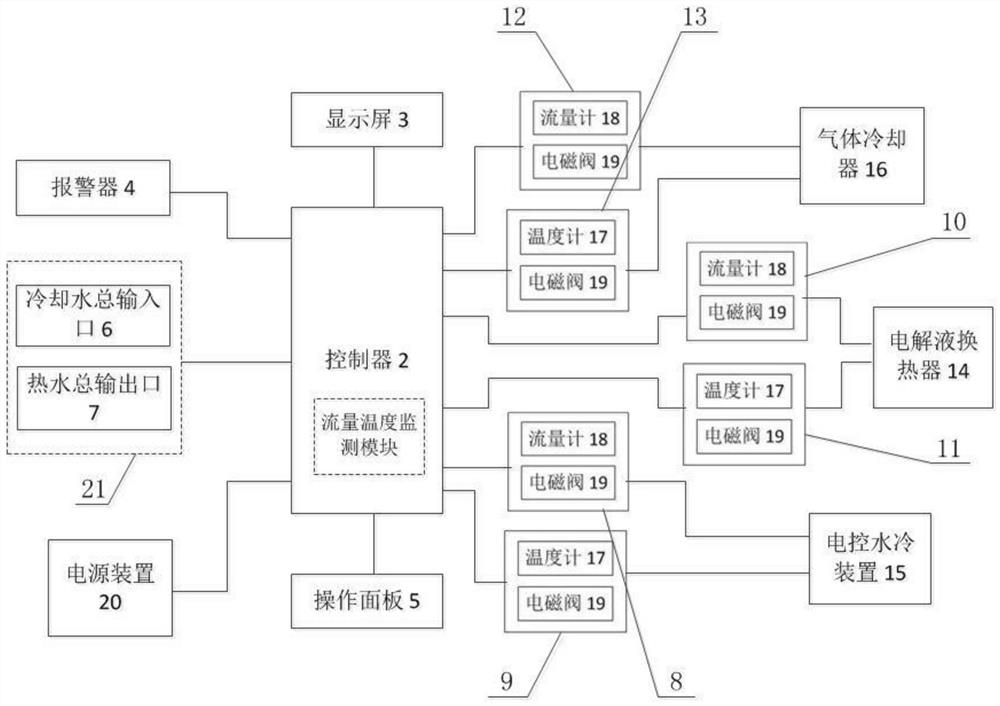

[0035] like image 3 As shown, on the basis of Embodiment 1, the cold and hot water treatment device 21 is set as a total cooling water input port 6 and a total hot water output port 7, cooling water is supplied through the cooling water total input port 6, and hot water is supplied through the heat The water main output port 7 is output to the outside for heating. Compared with the cold and hot water treatment device 21 set as the cooler 22 in the first embodiment, the cooling water in this embodiment needs to be supplied from the outside, and the hot water with residual heat is also When it is delivered to the outside for use, the present embodiment does not need to set the cooler 22, which reduces the power consumption of the cooler 22 for operation. In this embodiment, water tanks for storing cooling water and hot water are respectively provided in the management and control platform, and at the same time, solenoid valves 19 are provided on both the cooling water main inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com