A heat pipe air preheater

An air preheater and heat pipe technology, applied in the field of petrochemical industry, can solve the problems that the exhaust gas temperature cannot be adjusted, and the non-condensable gas cannot be effectively discharged, so as to avoid the reduction of heat transfer efficiency and ensure the effect of efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

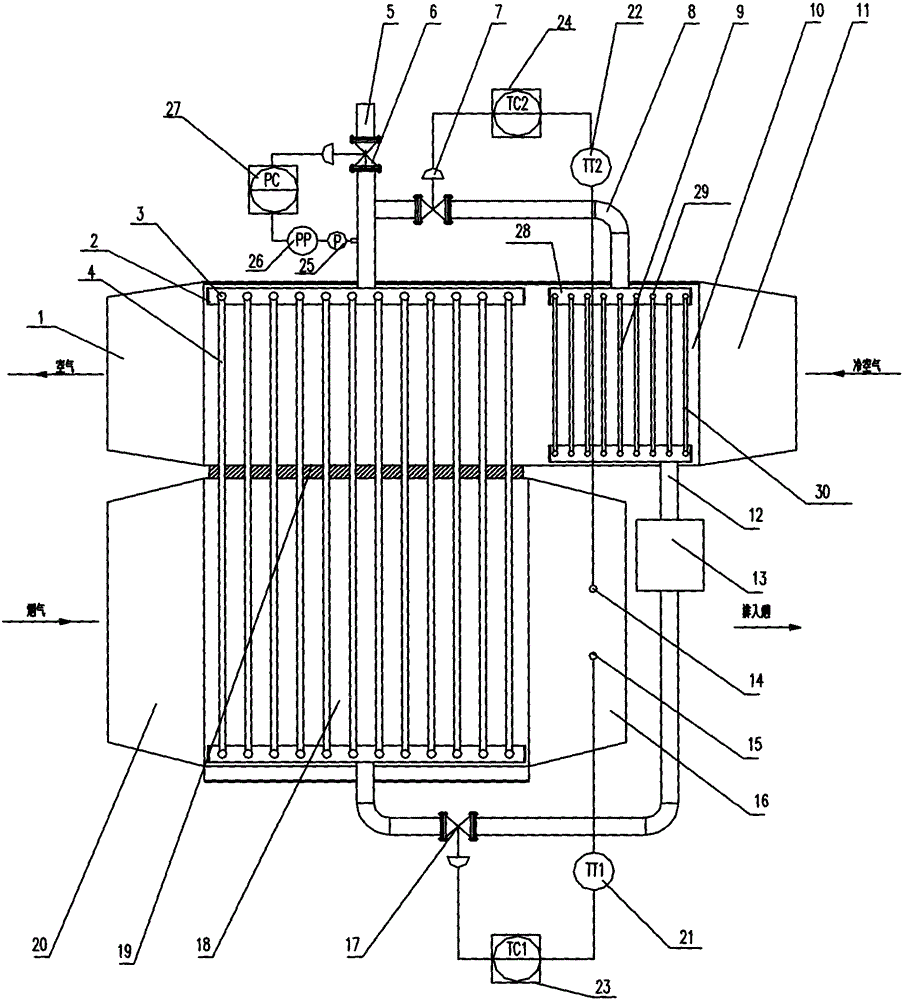

[0026] Such as figure 1 As shown, a heat pipe air preheater includes a flue gas pipe box 18 and an air pipe box 10, the flue gas pipe box 18 and the air pipe box 10 are separated by an intermediate partition 19, and one end of the flue gas pipe box 18 is connected The flue gas inlet section 20 is connected to the flue gas outlet section 16 at the other end. One end of the air pipe box 10 is connected to the air inlet section 11 , and the other end is connected to the air outlet section 1 .

[0027] figure 1 The heat pipe air preheater shown in the figure also includes a collection heat pipe group, a condenser 9, a medium distributor 13 and a control and regulating valve system. A collection heat pipe group is arranged in the flue gas pipe box 18 and the air pipe box 10, and the condenser 9 is arranged in the air Inside the pipe box 10, the control and regulating valve system includes an emptying valve 6, a steam regulating valve 7, thermocouples 14 and 15, and a medium regula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com