Thermal protection method for launch pad

A launch pad and thermal protection technology, applied in the direction of rocket launchers, offensive equipment, weapon types, etc., can solve problems such as inconvenient maintenance, poor craftsmanship of the launch pad, and uncontrollable costs, so as to suppress the scope of influence, save consumption costs, The effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

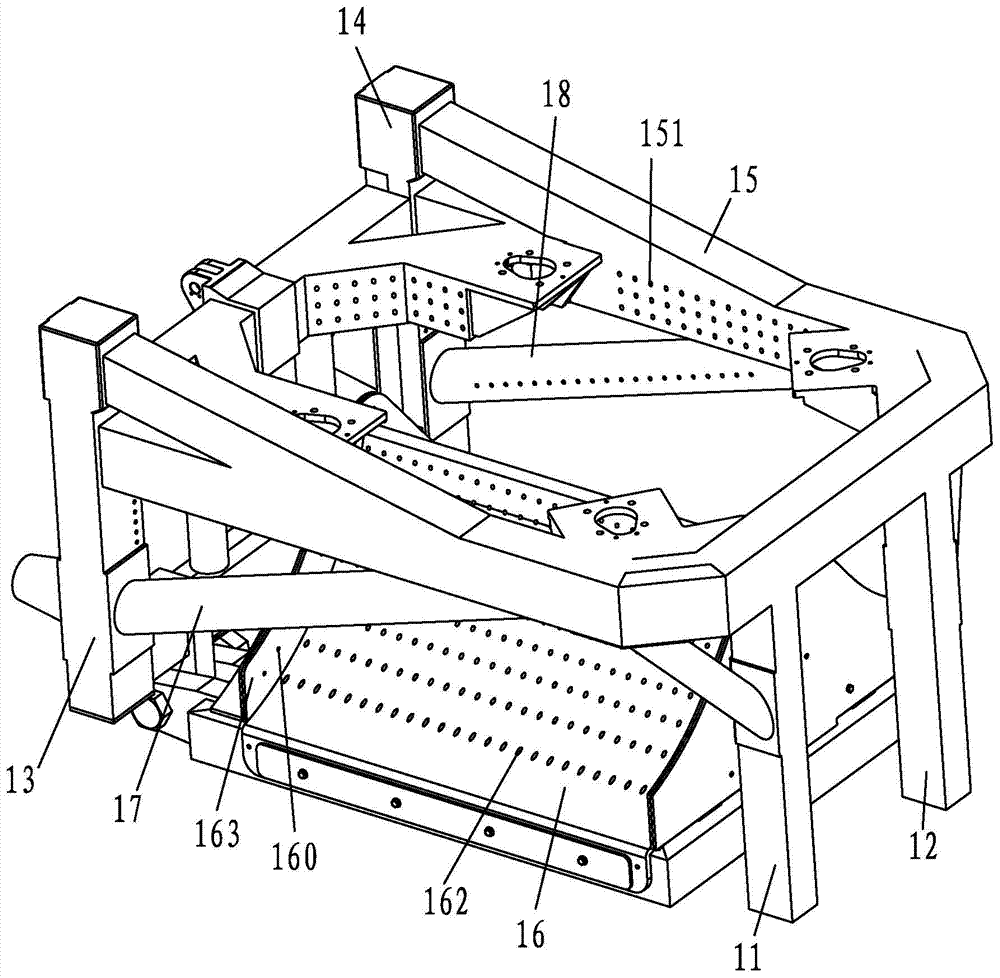

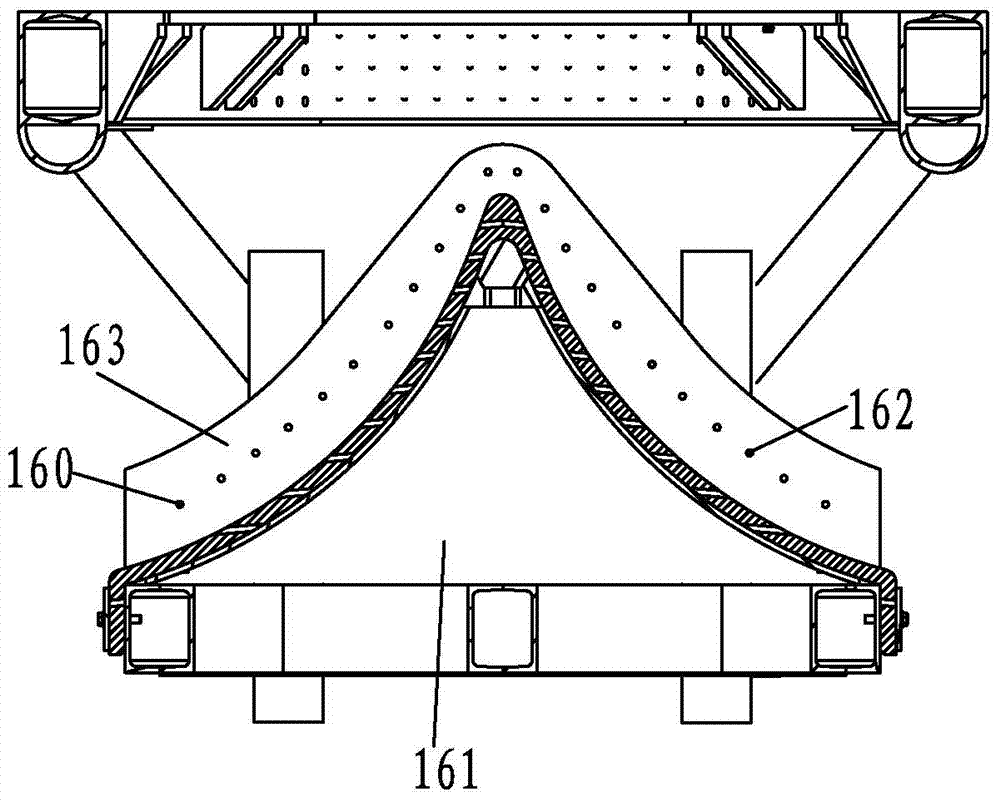

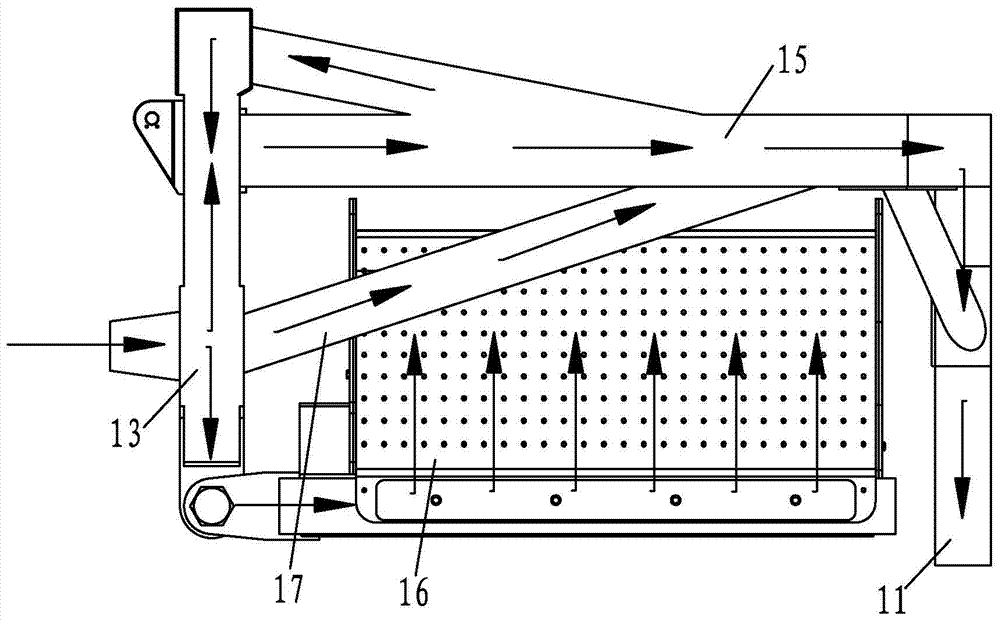

[0014] Such as figure 1 As shown, the water spray cooling type launching platform of the present invention comprises outer front and rear support columns 11,12, inner front and rear support columns 13,14, support ring frame 15, diversion cone 16, and support ring frame 15 is fixed on each support At the top of the column, the diversion cone 16 is fixed on the inner side of the bottom of each support column. Between the support ring frame 15 and the inner front and rear support columns 13, 14, there are respectively front and rear oblique supports 17, 18, and the outer front and rear support columns 11 and 12, the inner front and rear support columns 13 and 14, the support ring frame 15 and the front and rear oblique supports 17 and 18 are all hollow structures, and each hollow part forms each support column, support ring frame 15 and front and rear oblique supports respectively. Support the main water channel for water spraying on the support 17,18, the outer front and rear su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com