Sleeve-spliced rock direct tensile test device and method

A technique for tensile testing and rock test pieces, applied in the direction of measuring devices, applying stable tension/pressure to test material strength, instruments, etc., can solve problems such as difficult processing, stress concentration at clamping parts, and no steering mechanism , to achieve significant economic benefits, broad application prospects, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

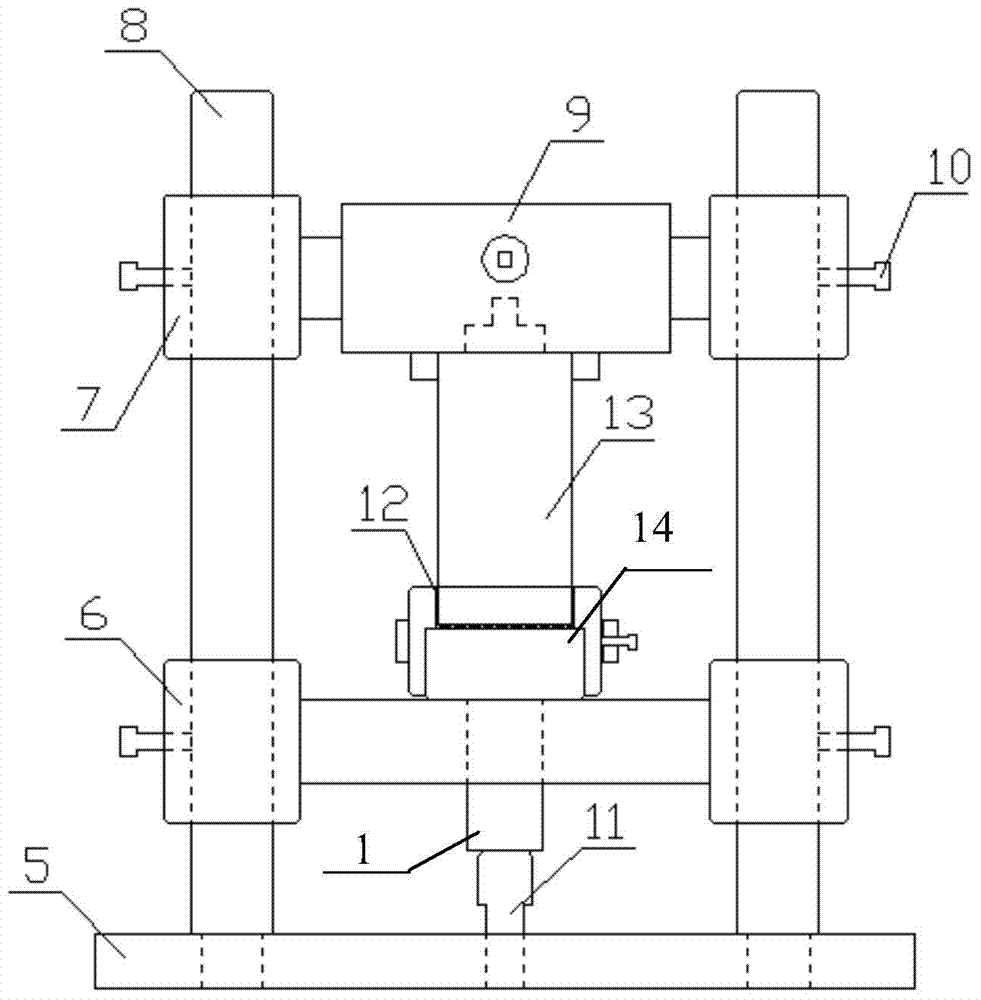

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

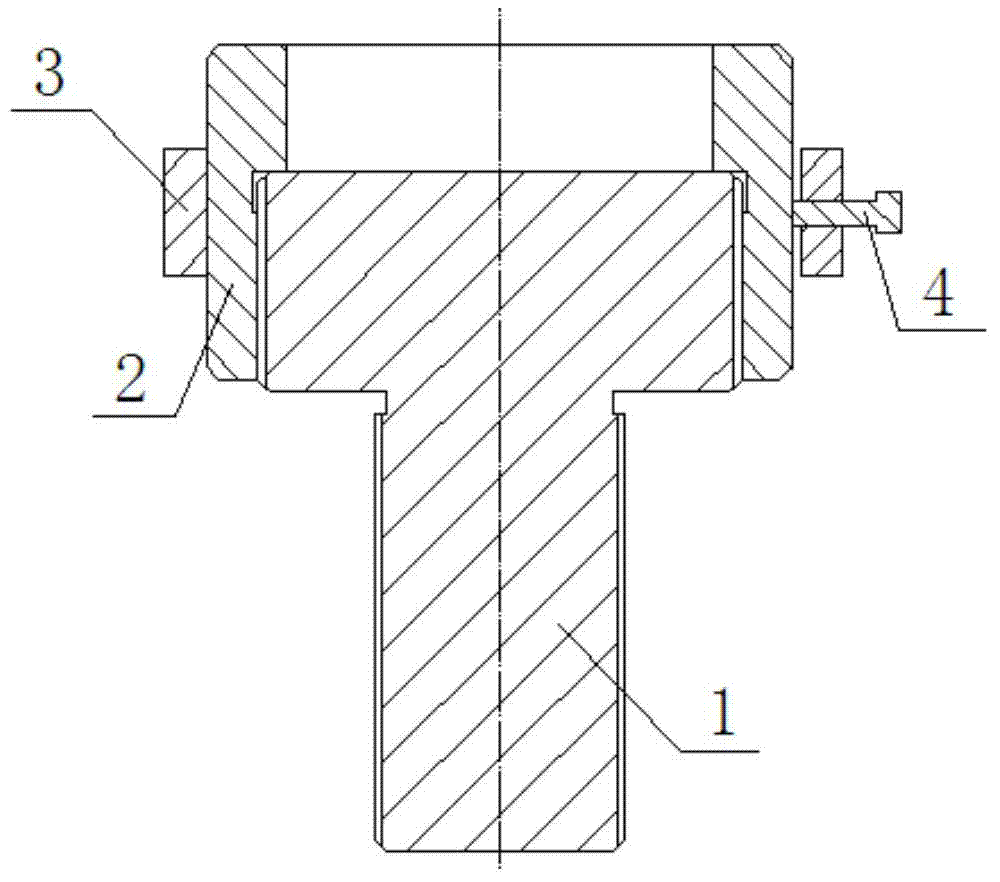

[0046] figure 1 Among them, the sleeve assembly 14 is mainly composed of a pull rod 1, a split sleeve 2, a tightening ring 3 and a fastening bolt 4. The split sleeve 2 and the pull rod 1 are connected by screws to form a cylindrical inner space with a diameter slightly greater than 50 mm, and are designed as split double-lobes for easy disassembly. The diameter of the tight hoop ring 3 is slightly larger than the outer diameter of the split sleeve 2, and is mainly used to hoop the sleeve.

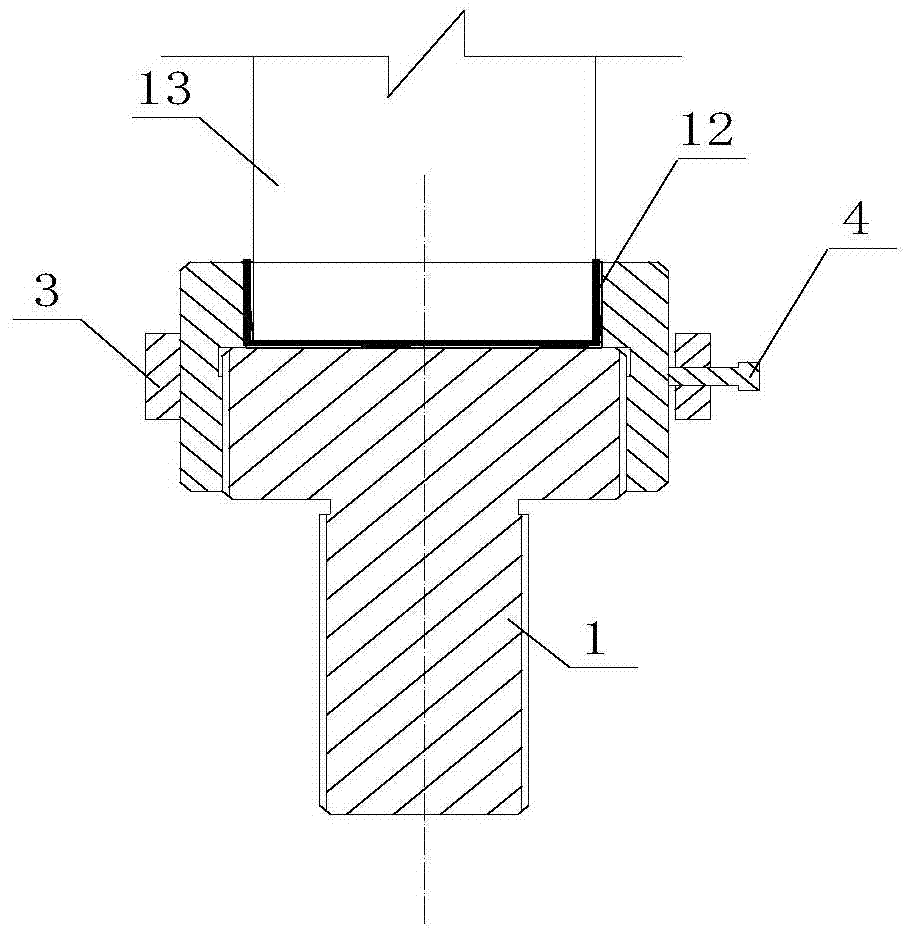

[0047] figure 2 Among them, the sleeve 14 is not only bonded to the end surface of the test piece 13, but also bonded to its side part. The viscose 12 on the end face of the test piece 13 bears the tensile stress, and the viscose 12 on the side of the test piece 13 bears the shear stress, thereby ensuring that the end of the test piece can bear a large tensile be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com