Pouring method of transformer

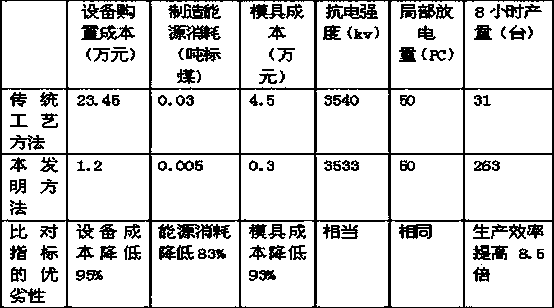

A casting method and technology for transformers, which are applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., to achieve the effect of reducing equipment cost, purchasing cost and manufacturing cost, and reducing process complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0009] The specific implementation of the technical solution of the present invention is as follows:

[0010] Step 1. Cleaning: Use the mixed solution of absolute ethanol + No. 20 solvent gasoline to clean the structural parts and molds of the castings, and use compressed air to clean the dust and other sundries on the castings.

[0011] Step 2. Assembly: Assemble and fix the product to be cast and the casting mold according to the drawing.

[0012] Step 3. Drying: Put the assembled product to be poured and the mold together in a drying oven for drying to remove moisture.

[0013] Step 4. Mixing the two-component resin of the castable: mix the two-component resin E5262 epoxy resin and E5262 curing agent in proportion, and the mass ratio of the mixing components is: E5262 epoxy resin 100: E5262 curing agent: 13.

[0014] Step 5. Pouring: Put the dried product to be cast and the mold assembly on the vibrating table, turn on the vibrating table, and vibrate while pouring, so tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com