Multidimensional quick-acting medlar powder and production method thereof

A production method and technology of Lycium barbarum polysaccharides are applied in the field of preparation of Lycium barbarum multidimensional effect instant powder, which can solve the problems of low active substance content and poor taste of Lycium barbarum fruit powder, and achieve the effects of improving efficacy quality, slightly sweet taste, and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

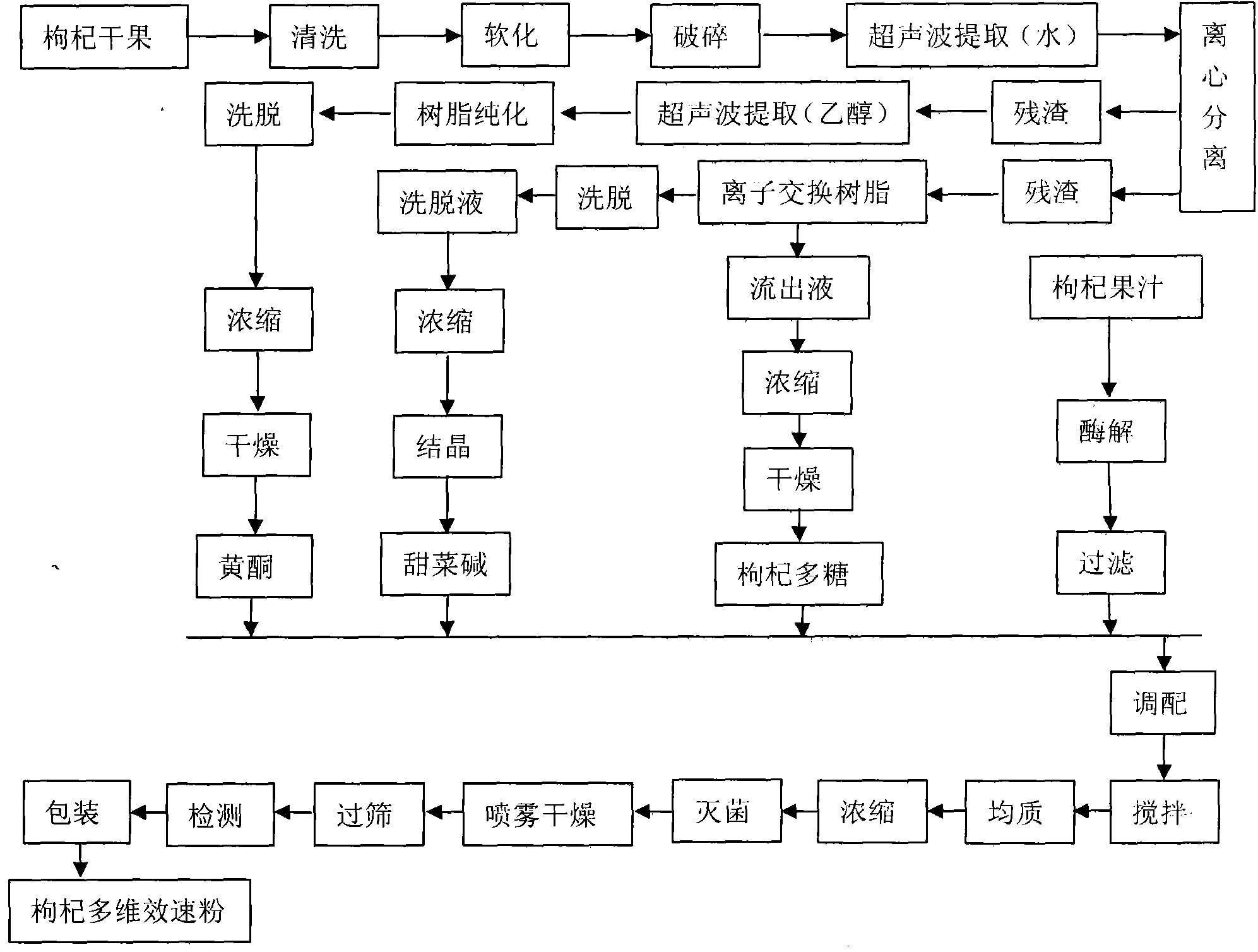

[0024] Embodiment 1 of the present invention: A production method of wolfberry multi-dimensional fast powder, comprising the following steps:

[0025] (1) Select fruit, wash, soften it with 25°C water for 1 hour, and the ratio of material to liquid is 1:10g / ml by weight and volume. After softening, beating and breaking into pulp;

[0026] (2) Ultrasonic extraction, centrifugal separation, and collect supernatant and residue respectively. During ultrasonic extraction, the material-to-liquid ratio of fruit pulp to water is 1:10g / ml by weight and volume, the extraction temperature is 20°C, the extraction time is 10min, and the extraction power is 50W. ;

[0027] (3) Put the collected residue into an ultrasonic extractor for extraction, concentration, separation and purification, and the obtained flavonoids. During ultrasonic extraction, the material-to-liquid ratio of residue to ethanol is 1:20g / ml by weight and volume, ethanol volume fraction is 25%, extraction time is 30min, extract...

Embodiment 2

[0032] Embodiment 2 of the present invention: a production method of wolfberry multi-dimensional fast powder, comprising the following steps:

[0033] (1) Select fruit, wash, soften it with 25℃ water for 4 hours, the ratio of material to liquid is 1:50g / ml by weight and volume, after softening, beating and crushing the fruit pulp;

[0034] (2) Ultrasonic extraction, centrifugal separation, and collect supernatant and residue respectively. During ultrasonic extraction, the material-to-liquid ratio of fruit pulp to water is 1:50g / ml by weight and volume, the extraction temperature is 60°C, the extraction time is 50min, and the extraction power is 250W. ;

[0035] (3) Put the collected residue into an ultrasonic extractor for extraction, concentration, separation and purification, and the obtained flavonoids. During ultrasonic extraction, the material-to-liquid ratio of residue to ethanol is 1:40 g / ml by weight and volume, ethanol volume fraction is 85%, extraction time is 110 min, ex...

Embodiment 3

[0040] Embodiment 3 of the present invention: A production method of wolfberry multi-dimensional fast powder, comprising the following steps:

[0041] (1) Select fruit, wash, soften it with 25℃ water for 2 hours, the ratio of material to liquid is 1:30g / ml by weight and volume, after softening, beating and crushing the fruit pulp;

[0042] (2) Ultrasonic extraction, centrifugal separation, and collect supernatant and residue respectively. During ultrasonic extraction, the material-to-liquid ratio of fruit pulp and water is 1:30g / ml by weight and volume, the extraction temperature is 30°C, the extraction time is 30min, and the extraction power is 150W. ;

[0043] (3) Put the collected residue into an ultrasonic extractor for extraction, concentration, separation and purification, and the obtained flavonoids. During ultrasonic extraction, the material-to-liquid ratio of residue to ethanol is 1:30g / ml by weight and volume, ethanol volume fraction is 70%, extraction time is 60min, extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com