Controlled rolling and controlled cooling system for bars

A technology of controlled rolling and controlled cooling, bar, applied in metal rolling, temperature control, metal rolling and other directions, can solve the problems of insufficient cooling capacity, low qualification rate, poor application adaptability, etc. Insufficient capacity, strong application adaptability, and the effect of improving cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The bar controlled rolling and controlled cooling system according to the present invention will be described in detail below with reference to the accompanying drawings. Those skilled in the art should understand that the specific embodiments described below are only illustrative illustrations of the present invention, and are not intended to limit the present invention in any way.

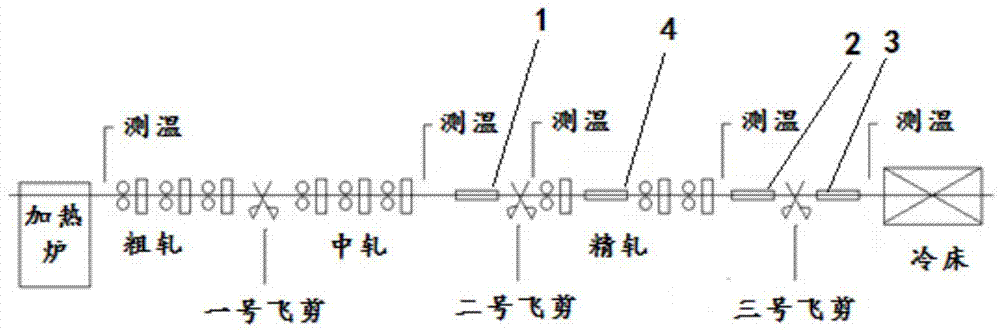

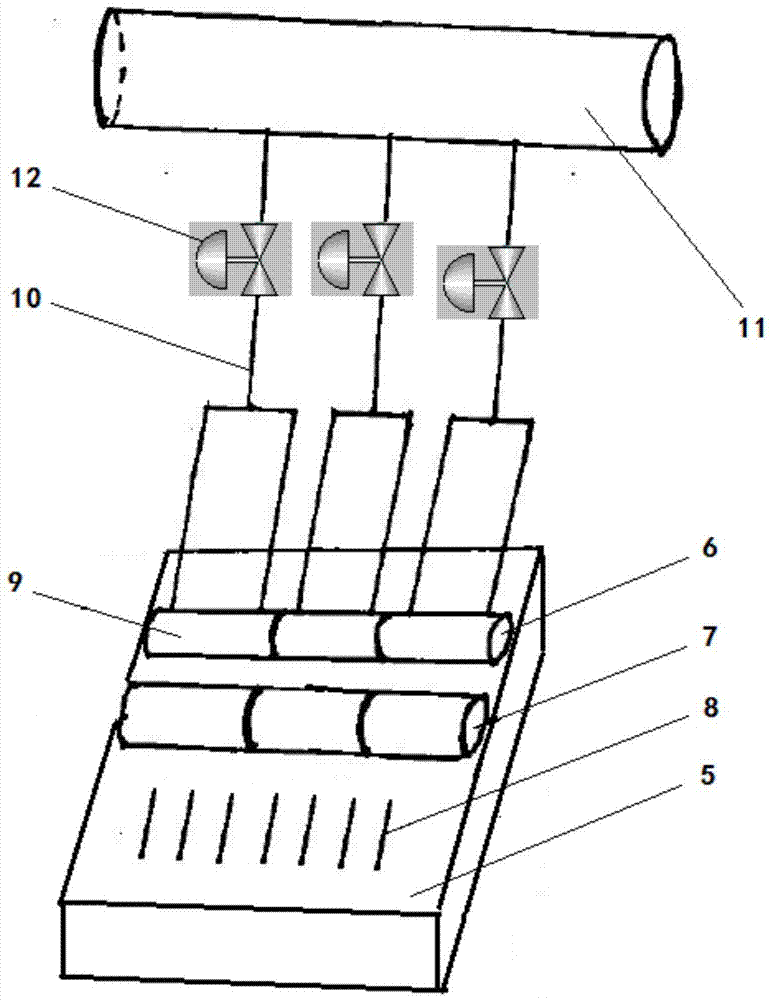

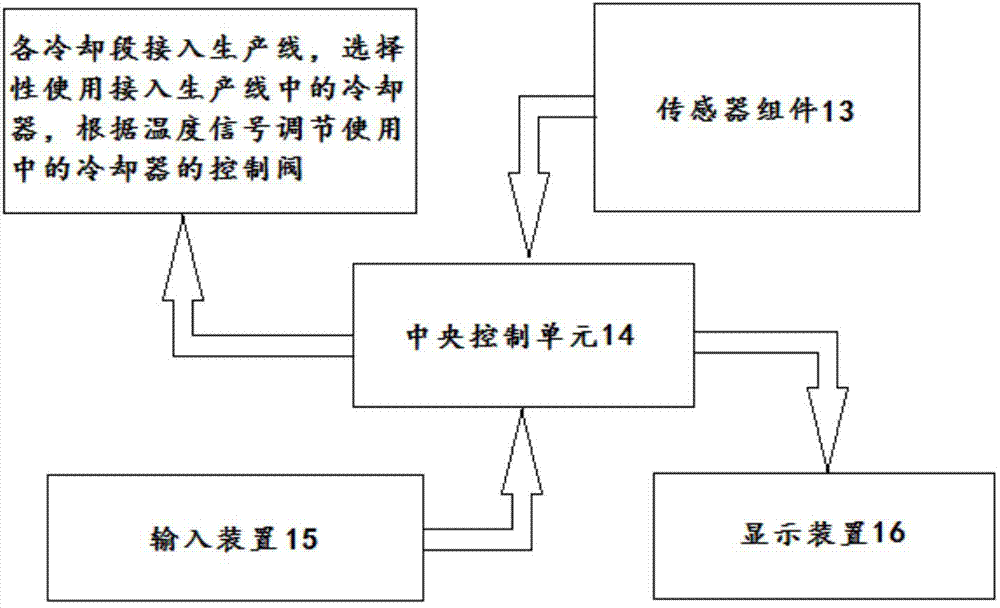

[0032] see first figure 1 , The steel bar rolling production line usually includes heating furnace, rough rolling, No. 1 flying shear, middle rolling, No. 2 flying shear, finishing rolling, No. 3 flying shear and cooling bed. According to a preferred embodiment of the present invention, the bar controlled rolling and controlled cooling system includes: the first cooling section 1, which is arranged between the outlet of the intermediate rolling group and the finishing rolling group; the inter-machine cooling section 4, which is arranged at the finishing Between the rolling mills, it shoul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com