Electrode gap control method and device for numerical control electrolytic machining

A technology of electrode gap and control method, which is applied in the direction of processing electrodes, electrode manufacturing, electric processing equipment, etc., can solve the problem of low measurement accuracy of electrode gap, and achieve the effect of small response time, fast response speed and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

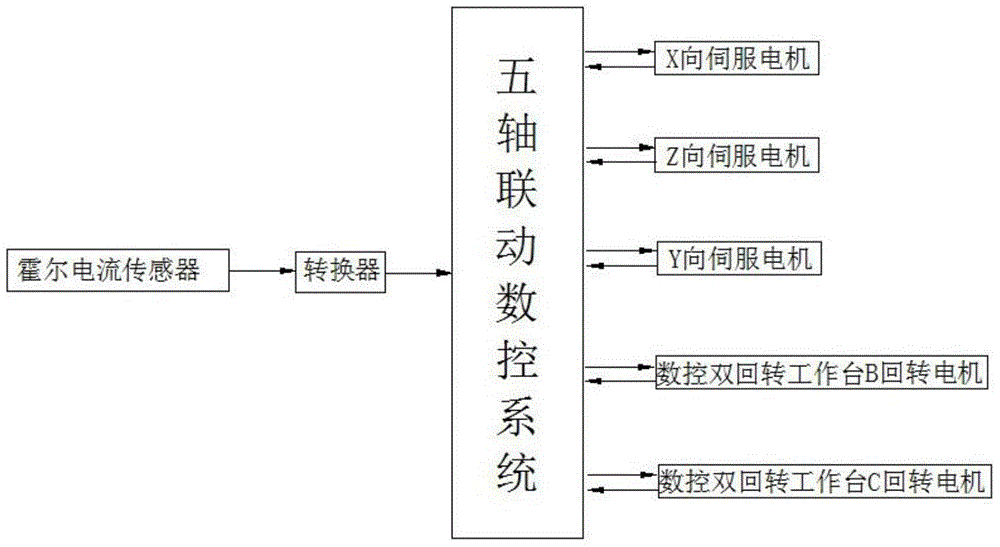

[0032] Taking the five-axis linkage numerical control electrolytic machining machine tool as an example, the electrode gap control method of numerical control electrolytic machining in this embodiment includes the following steps:

[0033] (1) Measurement of the electrode gap: In the five-axis linkage CNC electrolytic machining, the gap between the rotating cathode and the workpiece anode is filled with electrolyte, and under the action of the electric field, the positive ions in the electrolyte move to the tool cathode, forming a The positive current flow from the anode to the rotating cathode creates a current field. Although the electrode gap is affected by many factors, it is mainly affected by the gap electric field. Therefore, the electrode gap is analyzed based on the assumption of electric field simplification and Faraday's law of electrolysis, and the approximate formula of the electrode gap is derived, which shows that the machining current is inversely proportional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com