Water surface oil stain cleaning ship

A technology for water surface oil pollution and ship cleaning, which is applied in the direction of open water surface cleaning, general water supply conservation, water conservancy projects, etc. The effect of improving oil absorption efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the embodiments shown in the accompanying drawings.

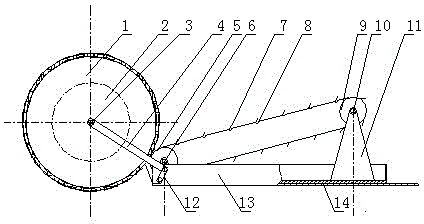

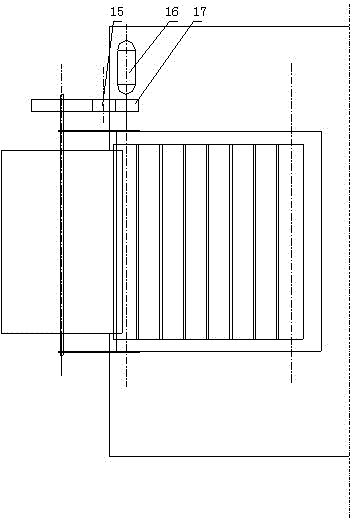

[0015] The components in the picture are: 1 oil suction roller, 2 gears, 3 shafts, 4 connecting rods, 5 driving wheels, 6 shafts, 7 oil scrapers, 8 oil flow grooves, 9 driven wheels, 10 shafts, 11 brackets, 12 adjustment rods, 13 oil sumps, 14 hulls, 15 gears, 16 motors, 17 gears.

[0016] The water surface oil cleaning ship consists of an oil suction roller 1, an oil scraper 7, an adjustment rod 12, an oil sump 13, a hull 14 and a motor 16, an oil suction roller 1 is arranged in front of the hull 14, and several oil flow channels 8 are arranged below the oil scraper 7, In order to ensure the oil scraping effect, gear 17, gear 15, and gear 2 are meshed to realize the clockwise rotation of oil suction roller 1 and oil scraper 7. During operation, the oil stain adsorbed on oil suction roller 1 is scraped off by oil scraper 7, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com