Floating production storage and offloading (FPSO) cargo oil tank cleaning method

A technology for cargo oil tanks and cabins, which is applied to the cleaning equipment of ship liquid tanks, oil tank ships, special-purpose ships, etc., and can solve the problems of increasing operation risks, personnel costs, long time, and increasing environmental protection costs, and achieves the reduction of sewage Amount of production, shortening of contact time, effect of relieving nervous fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

[0032] The core of the present invention is to provide a method for washing the FPSO cargo oil tank, so as to realize the washing operation of the FPSO cargo oil tank with high efficiency, low risk and low cost.

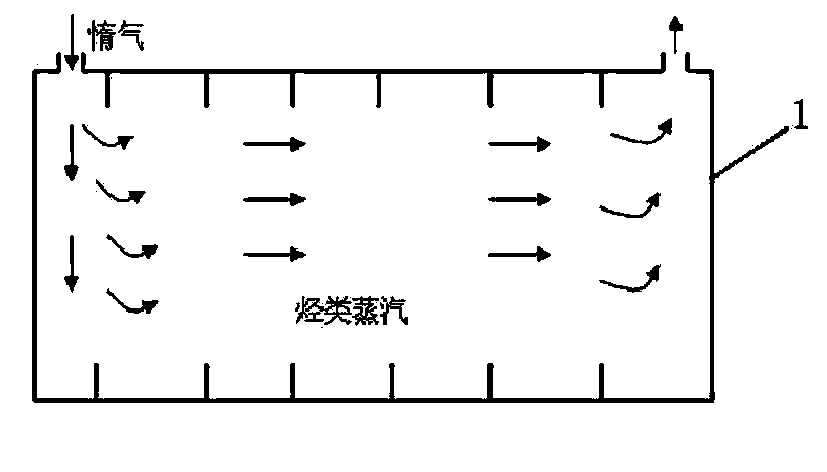

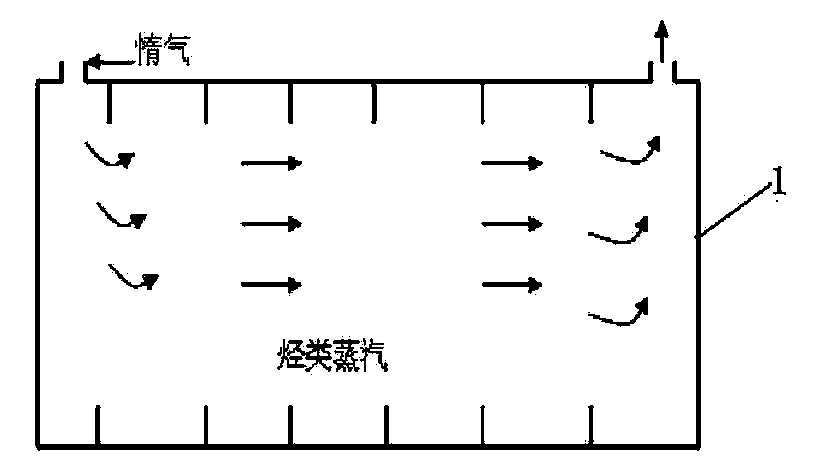

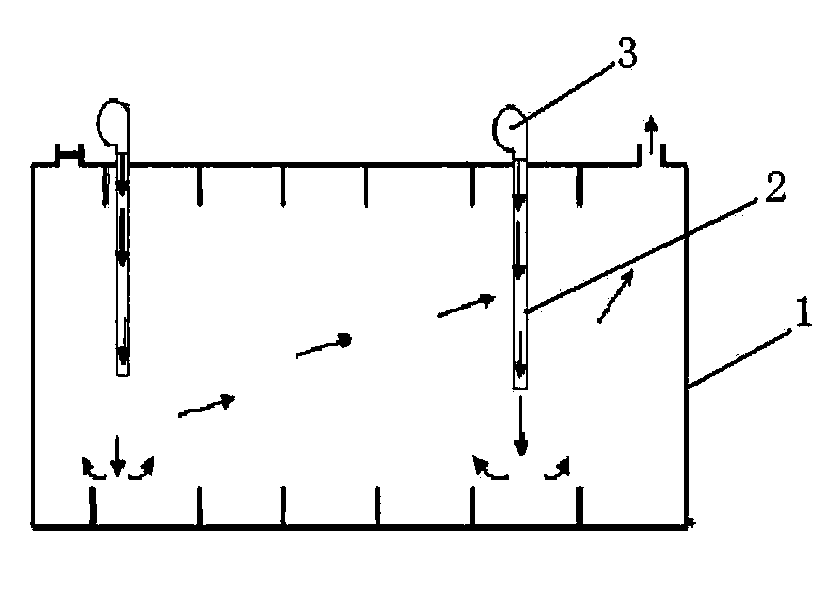

[0033] The FPSO cargo oil tank washing method described in the present invention integrates the traditional tank washing procedures, and proposes an optimized tank washing procedure: preliminary preparation → gas purging, production water disturbance tank washing, tank stripping → degassing → personnel entering the tank → Battering and inerting. During the gas purging stage of the FPSO cargo oil tank, the production water disturbance washing is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com