A sealing device for a soft bag infusion production line and a soft bag infusion production line

A soft bag infusion and sealing device technology, applied in the field of medical packaging, can solve the problems of scattered parts layout, inability to achieve sealing, scattered parts layout, etc., and achieve the effect of simple and compact structure, stable and reliable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

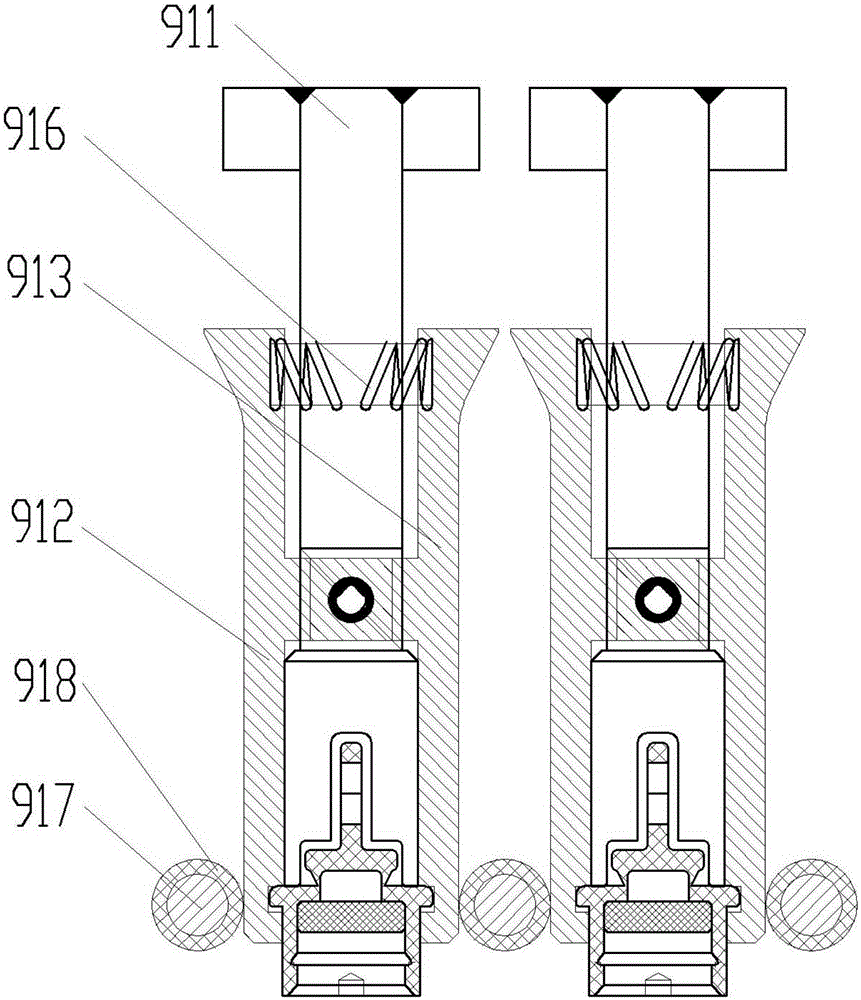

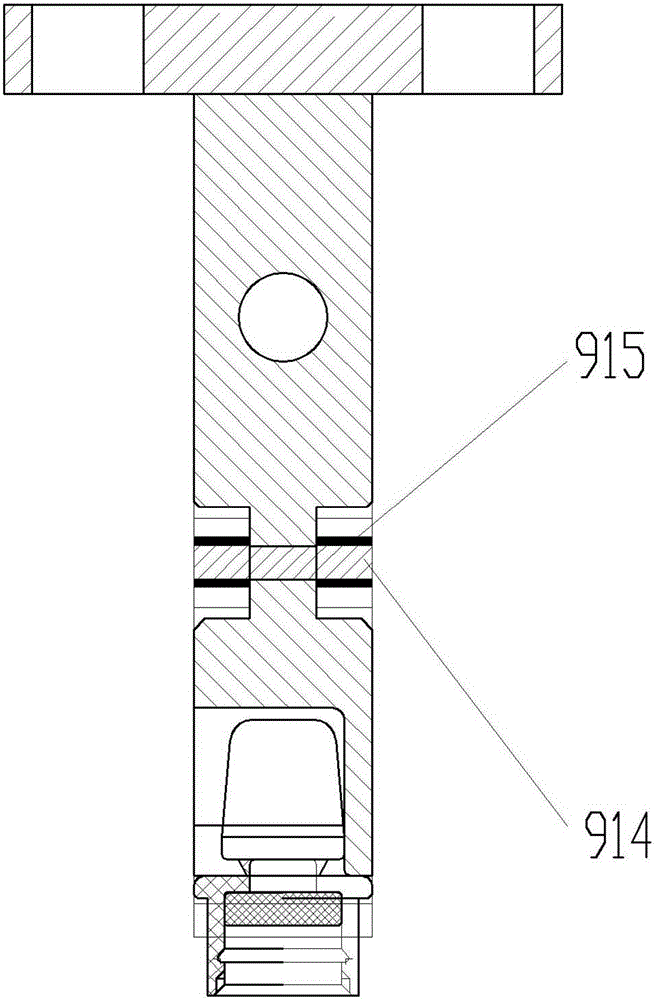

[0024] This embodiment provides a sealing device for a soft bag transfusion production line, please refer to figure 1 and figure 2 , the sealing device comprises: a cover cap 911, a left pivot arm 912 and a right pivot arm 913, the left pivot arm 912 and the right pivot arm 913 are sealed with the cap removal via a pin shaft 915 and a composite bearing 914 The cap 911 is fixedly connected.

[0025] The top ends of the left turning arm 912 and the right turning arm 913 are arranged in an inverted trapezoidal structure, and a small supporting shaft 917 and a compound roller 918 are arranged adjacent to the outside of the left turning arm 912 and the right turning arm 913 , the small pivot 917 and the compound roller 918 can move up and down along the outer arms of the left turning arm 912 and the right turning arm 913 .

[0026] A compression spring 916 is installed between the left turning arm 912 and the right turning arm 913 at the top inverted trapezoidal structure.

Embodiment 2

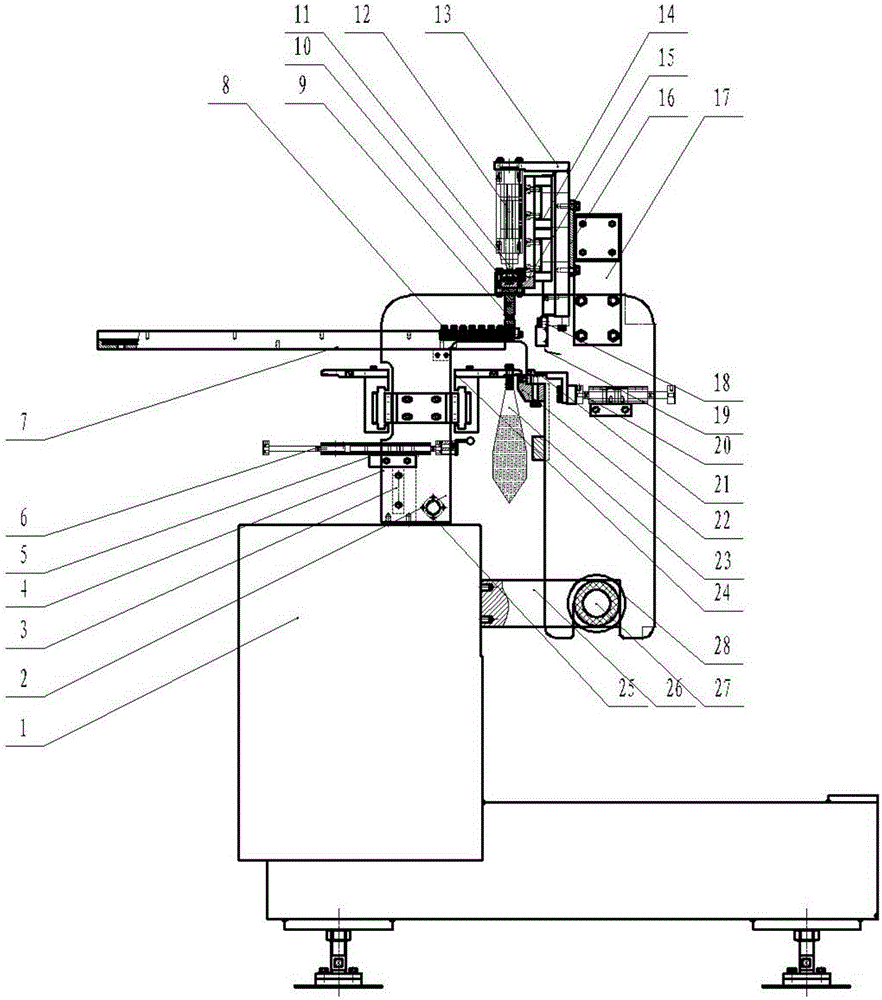

[0028] This embodiment provides a soft bag infusion production line, please refer to Figure 1 to Figure 4 , the soft bag infusion production line includes a frame 1, the left and right wall panels 2 are connected and fixed through the support plate 3 and the fixed plate 5, and the support plate 3 cooperates with the splint 4 and the sliding sleeve 28 cooperates with the support shaft 27 and the fixed support plate 26. On rack 1. In the actual operation process, if it is necessary to adjust the working pitch between the sealing devices, the forward and reverse rotation of the screw in the screw adjustment assembly 25 can be used to realize the left and right movement of all parts including the left and right wall panels 2, and by setting the The marking scale on the installation surface of rack 1 is used to determine the moving distance, so that the same set of sealing device can be used on the same equipment to seal the single-port soft bag infusion and double-port soft bag i...

Embodiment 3

[0034] This embodiment provides a soft bag infusion production line, please refer to figure 1 , figure 2 , Figure 5 and Figure 6 , on the basis of the specific structure of the second embodiment, the soft bag infusion production line adds a sealing cylinder 29 and a heating assembly 30 for heating the interface between the sealing cover 8 and the soft infusion bag 23, and the rest of the structure is the same as that of the second embodiment.

[0035] The operating principle of the soft bag transfusion production line of this embodiment is:

[0036] The principle is basically the same as that of Embodiment 2, except that there is one more process of removing the cap and heating corresponding to the structure of the production line: that is, the sealing cap 8 completes the cap removing process as described above and reaches directly above the heating assembly 30 . Similarly, the infusion soft bag 23 that has been filled and is to be sealed also arrives directly below the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com