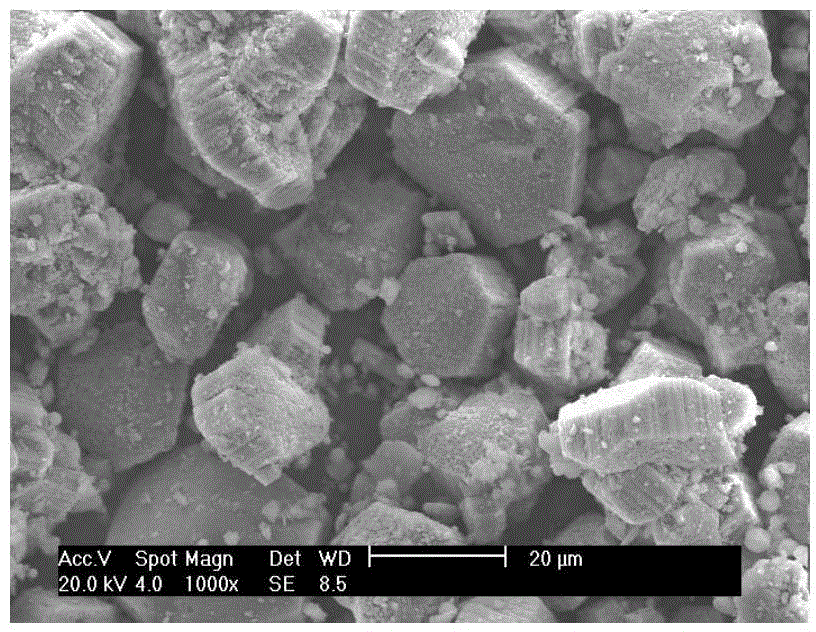

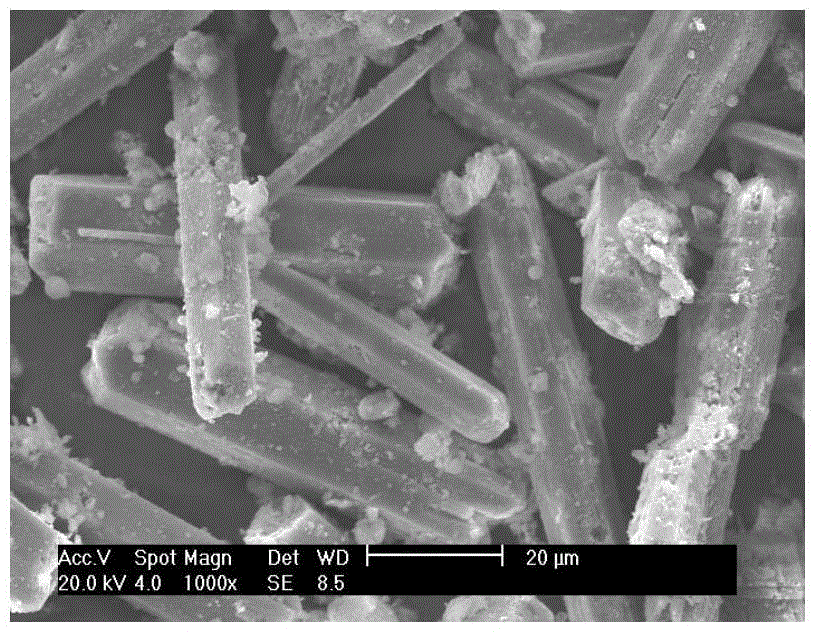

Method for preparing high-strength alpha-semi-hydrated gypsum from flue gas desulfurization gypsum

A technology of desulfurized gypsum and hemihydrate gypsum, applied in the field of material science, to achieve the effects of environmental protection, simple equipment, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

[0016] The preparation of the high-strength short hexagonal columnar α-hemihydrate gypsum provided by the present invention mainly includes the following steps in its technical scheme:

[0017] 1) Preparation of desulfurization gypsum slurry: Mix flue gas desulfurization gypsum and water at a solid-to-liquid mass ratio of 1:4-10, stir for 1-2 hours to fully mix, and then heat up to 80-95°C.

[0018] 2) Adding a crystallization agent to prepare a mixed slurry: Add the mass ratio of flue gas desulfurization gypsum to crystallization agent to the desulfurization gypsum slurry obtained in step 1) at a mass ratio of 1:0.5 to 1.5. The crystallization agent is magnesium chloride hexahydrate and hexahydrate The mixture of magnesium sulfate, the mass ratio of magnesium chloride hexahydrate and magnesium sulfate hexahydrate is 1:0.1~0.2; continue to heat up to boiling (107~108°C), and reflux.

[0019] 3) Add crystallization habit modifier: accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com