Preparation method of high grain orientation piezoceramic material

A piezoelectric ceramic, high-grain technology, applied in the field of piezoelectric ceramic material preparation, can solve the problems of low degree of orientation and density, and achieve the effect of improving sensitivity and promoting application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A High Grain Oriented Piezoelectric Ceramic Material Ca 2 Nb 2 o 7 The preparation method:

[0042] (1) Prepare spherical powder Ca by solid phase method combined with ball milling process 2 Nb 2 o 7

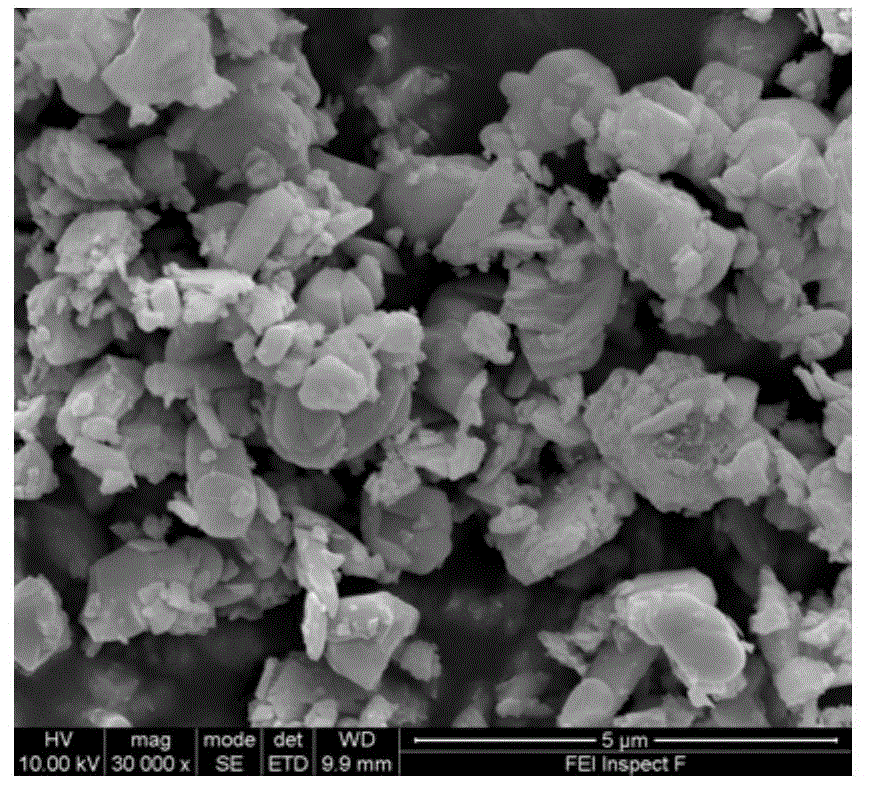

[0043] CaCO 3 and Nb 2 o 5 According to the molar ratio of 2:1, use a planetary ball mill to mix for 2 to 4 hours at a speed of 500 rpm. After drying, the ball-milled powder is synthesized in an atmospheric atmosphere. The synthesis temperature is 1250 ° C and kept for 4 hours; Ca 2 Nb 2 o 7 Ceramic powder, the ceramic powder is ball milled and mixed for 24 hours at a speed of 500 rpm with a planetary ball mill to make Ca 2 Nb 2 o 7 The particle size of the powder is fine and evenly distributed, and the spherical powder Ca 2 Nb 2 o 7 , spherical powder Ca 2 Nb 2 o 7 The SEM picture is as follows figure 1 shown.

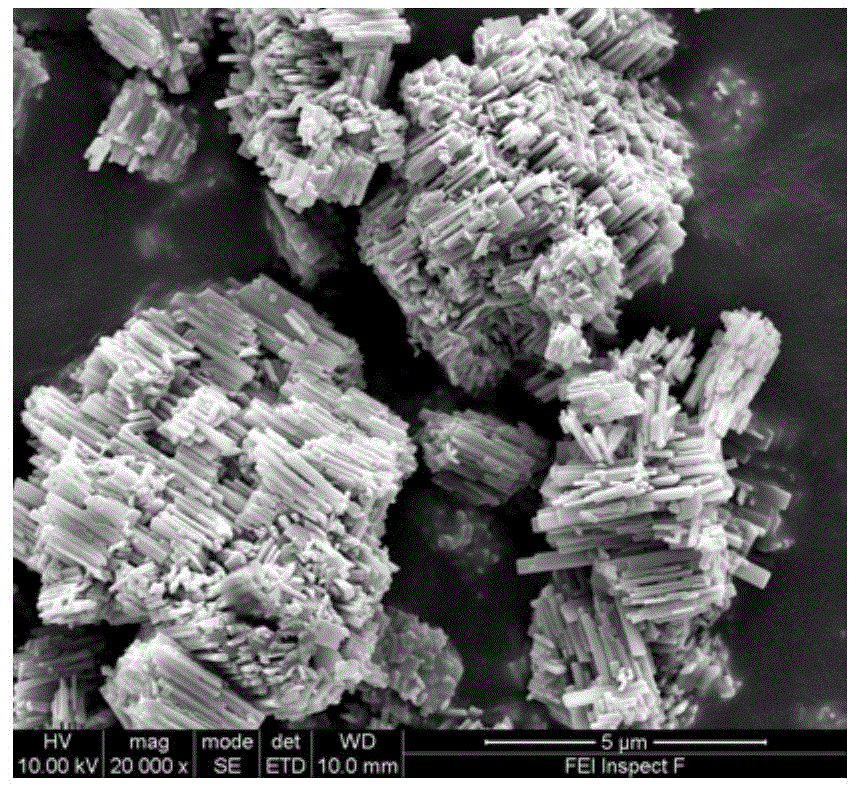

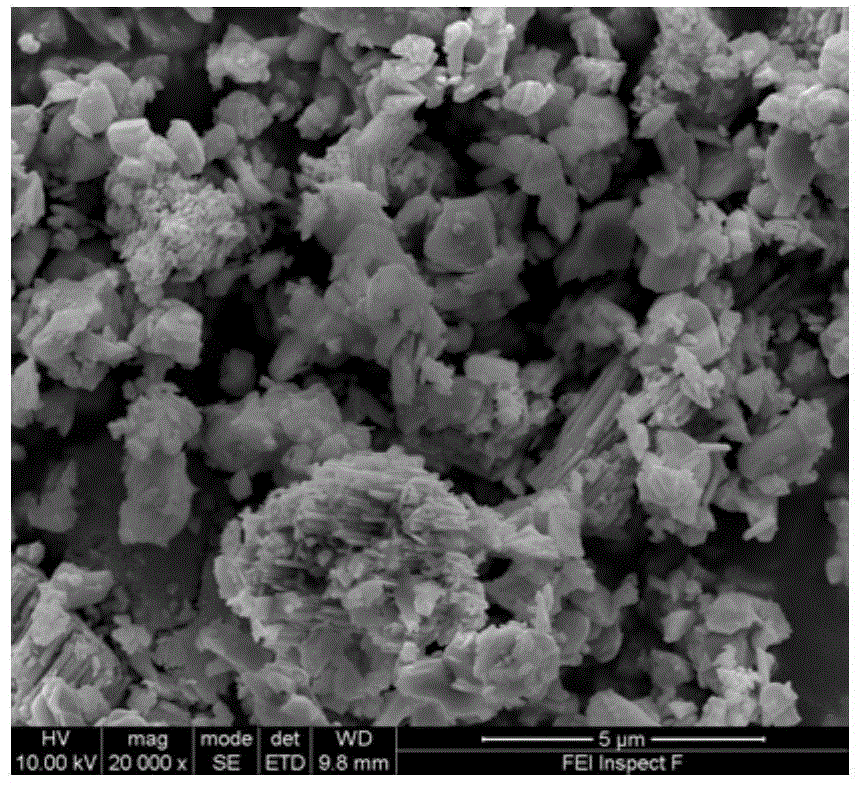

[0044] (2) The flake powder Ca 2 Nb 2 o 7

[0045] (a) The case of molten salt method at 1000°C:

[0046] CaCO 3 , Nb 2 o 5 , NaCl ...

Embodiment 2

[0055] High Grain Oriented Nd 2 Ti 2 O 7 The preparation method of ceramic, the Nd 2 O 3 and TiO 2 According to the molar ratio of 1:2, use a planetary ball mill at 500 r / min for ball milling and mixing for 2 to 4 hours. After drying, the ball-milled powder is synthesized in the atmospheric atmosphere, and the synthesis temperature is 1150 ° C for 4 hours; that is, the composition is obtained. Nd 2 Ti 2 O 7 ceramic powder. The ceramic powder was ball-milled and mixed with a planetary ball mill at 500 rpm for 24 hours to make Nd 2 Ti 2 O 7 The particle size of the powder is fine and the distribution is uniform, and the spherical powder Nd is obtained. 2 Ti 2 O 7 .

[0056] will Nd 2 O 3 , TiO 2 , NaCl and KCl according to the molar ratio of 1:2:9:9 with a planetary ball mill at a speed of 500 r / min for 4 hours, and after drying, the ball-milled powder was synthesized in the atmosphere, and the synthesis temperature was 1100 ℃ Incubate for 4 hours; then the syn...

Embodiment 3

[0059] A High Grain Oriented Piezoelectric Ceramic Material Sr 2 Nb 2 O 7 The preparation method:

[0060] (1) Preparation of spherical powder Sr by solid-phase method combined with ball milling process 2 Nb 2 O 7

[0061] SrCO 3 and Nb 2 O 5 According to the molar ratio of 2:1, use a planetary ball mill at 500 r / min for ball milling and mixing for 2 to 4 hours. After drying, the ball-milled powder is synthesized in the atmospheric atmosphere, and the synthesis temperature is 1250 °C for 4 hours; that is, the composition is obtained. Sr 2 Nb 2 O 7 The ceramic powder was mixed with a planetary ball mill at 500 rpm for 24 hours to make Sr 2 Nb 2 O 7 The particle size of the powder is fine and the distribution is uniform, and the spherical powder Sr is obtained. 2 Nb 2 O 7 .

[0062] (2) Preparation of flake powder Sr by molten salt method 2 Nb 2 O 7

[0063] SrCO 3 , Nb 2 O 5 , NaCl and KCl according to the molar ratio of 2: 1: 9: 9 with a planetary ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| service temperature | aaaaa | aaaaa |

| Orientation degree | aaaaa | aaaaa |

| Orientation degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com