Barium titanate-based leadless electrostrictive ceramic and preparation method thereof

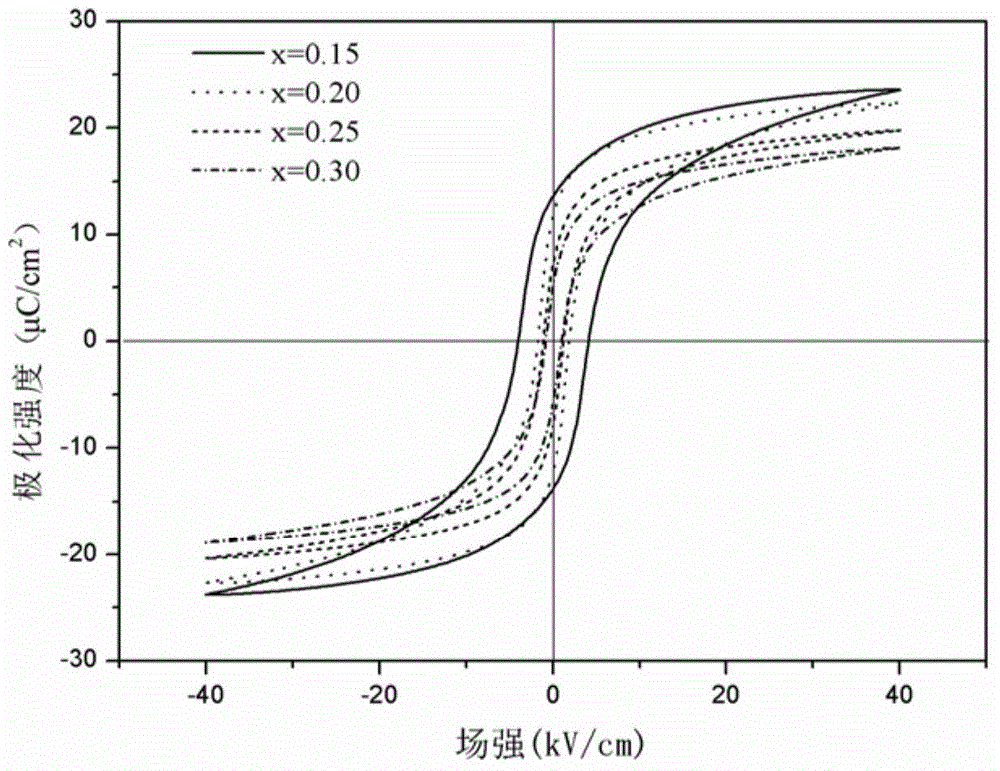

A technology of stretching and barium titanate, which is applied in the field of BZT-BCT barium titanate-based lead-free electrostrictive ceramics and its preparation, can solve problems such as environmental and human hazards, limit lead, etc., and achieve easy operation, large electrostrictive Stretch strain, good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

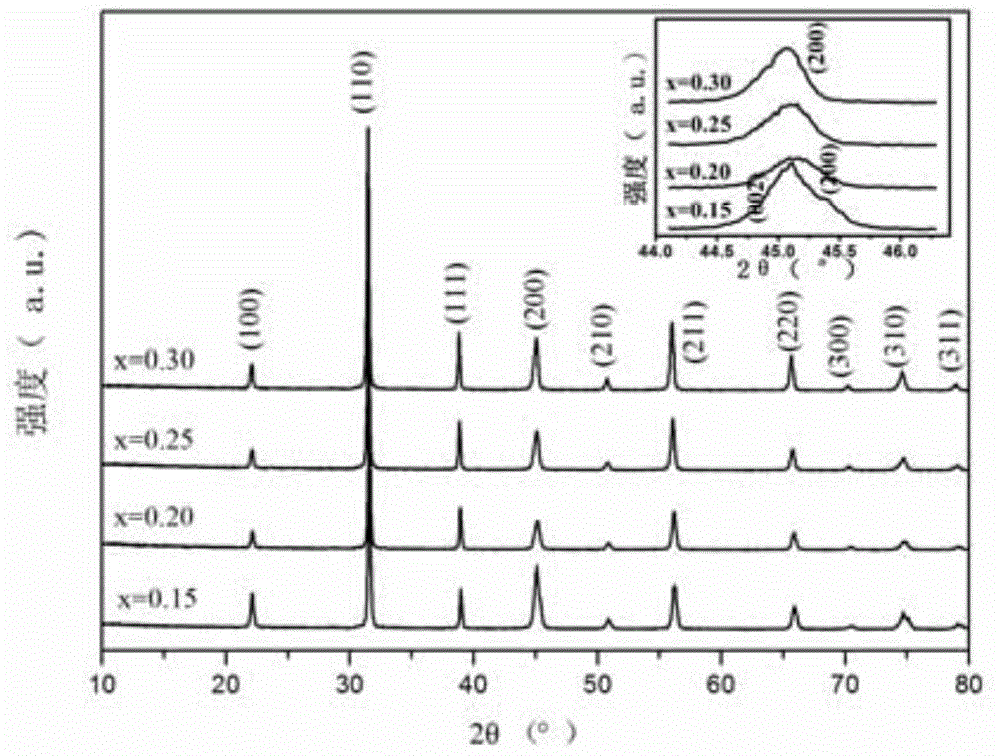

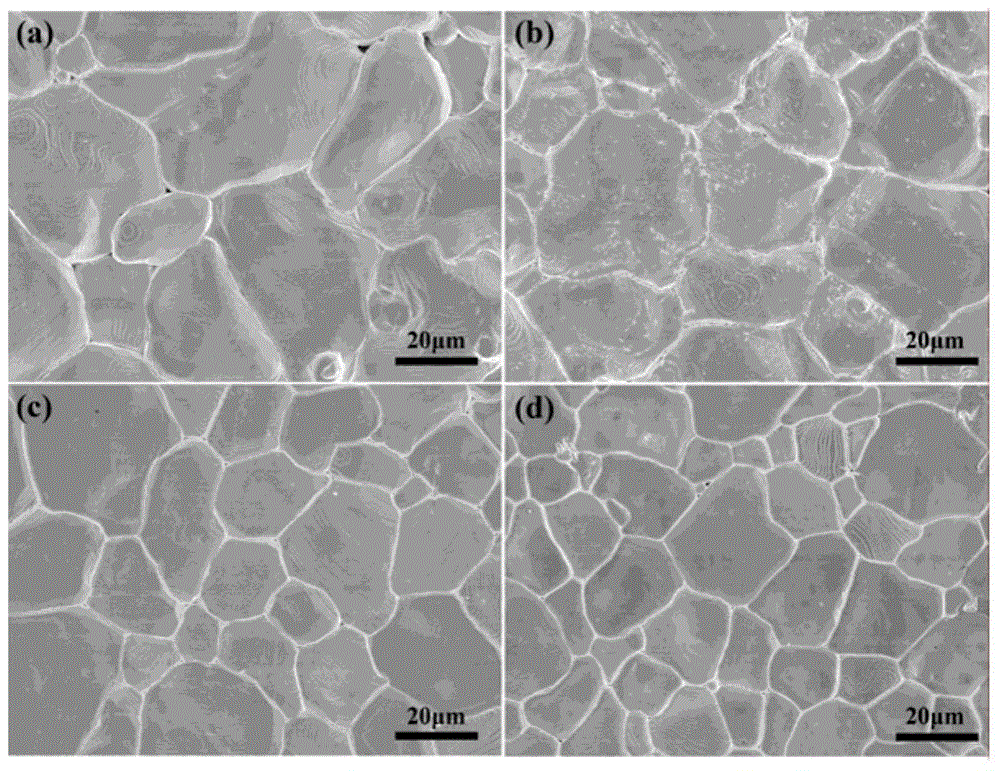

[0037] The preparation method of the barium titanate-based lead-free electrostrictive ceramics adopts a solid-phase synthesis method, and the preparation steps are as follows:

[0038] (1) Ingredients synthesis

[0039] According to 50Ba(Zr x Ti 1-x )O 3 -50(Ba 0.75 Ca 0.25 )TiO 3 , where the stoichiometric ratio of x=0.15~0.30 weighs the original BaCO 3 , CaCO 3 , ZrO 2 and TiO 2 , into the ball mill tank, the ball milling medium is water and agate balls, ball: material: the weight ratio of water is 2: 1: 0.6, ball milling 4h, ball milling speed is 800 rpm, then the mixture is put into the oven for 80 Dry at ℃, put it into a mortar and grind it, and pass through a 40-mesh sieve;

[0040] (2) pre-burning

[0041] Put the ground and sieved powder in step (1) into a crucible, compact it with an agate rod, cover it, and seal it; pre-fire it in a muffle furnace at 1200 ° C, keep it warm for 4 hours, and cool it down to room temperature naturally. baked;

[0042] (3) S...

Embodiment 1

[0056] Example 1: x=0.15, the sintering temperature is 1400°C;

Embodiment 2

[0057] Example 2: x=0.20, the sintering temperature is 1400°C;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com