Production improvement method for corn starch

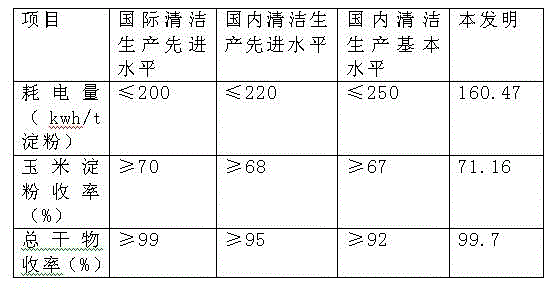

A technology of corn starch and corn, which is applied in the field of corn starch production, can solve the problems of not being able to reach the international advanced level of clean production in the starch industry, and achieve the effects of easy production and processing and improved production level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

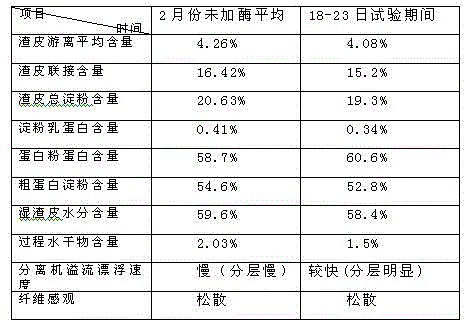

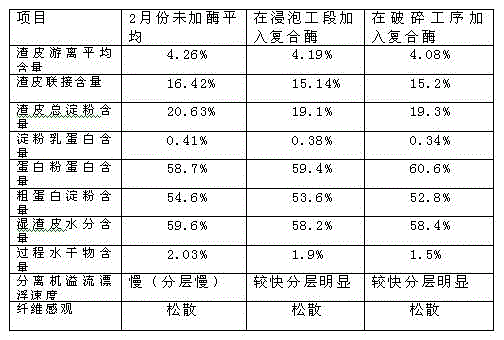

Examples

Embodiment 1

[0041] A kind of production improvement method of cornstarch, concrete steps are as follows:

[0042] a. Purification process

[0043] The raw corn is sent to the metering scale through the bucket elevator, and then sent to the multi-stage self-horizontal vibrating screen after metering. The impurities larger than the corn are screened out by the first sieve, and the impurities smaller than the corn are screened out by the second The sieve is removed from the bottom of the sieve, and the side-by-side stone impurities with the same volume as the corn enter the corn washing tank together with the corn. The impurities are blocked by the multi-level vertical ladder baffle in the washing tank, and the metal impurities are attracted by the magnet in the tank, and are removed after parking. Light and small corn dust and corn coat impurities are sucked away by the induced draft fan from the outlet of the bucket elevator and the inlet of the multi-stage vibrating screen and stored in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com