Mineral oil type steam cylinder oil composition and preparation method and application thereof

A technology of cylinder oil and composition, applied in the field of materials, can solve the problems of cylinder corrosion and stress damage, oil film thinning, sealing failure, etc., and achieve the effects of low cost, prolonging service life and reducing failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

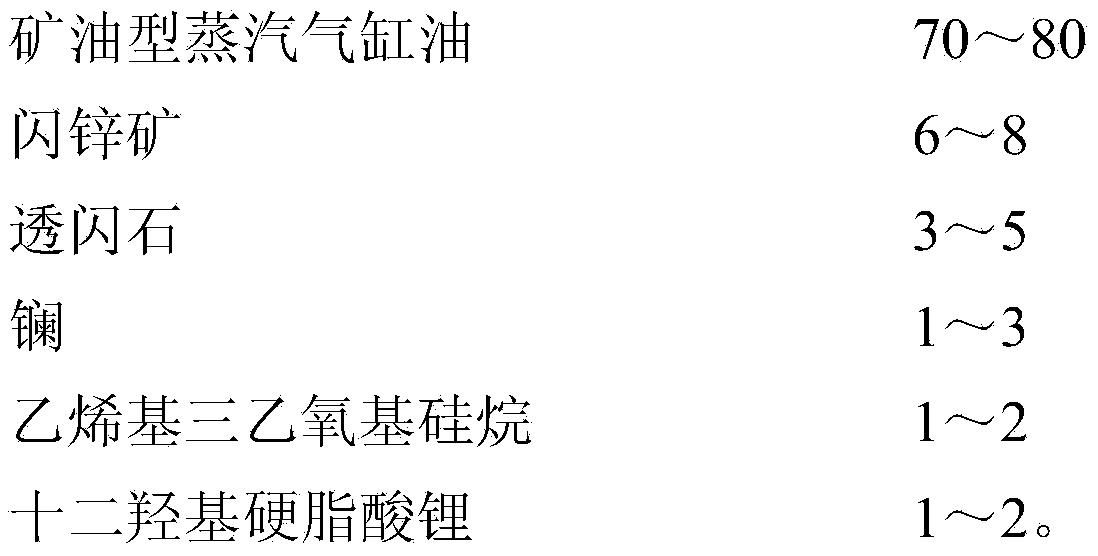

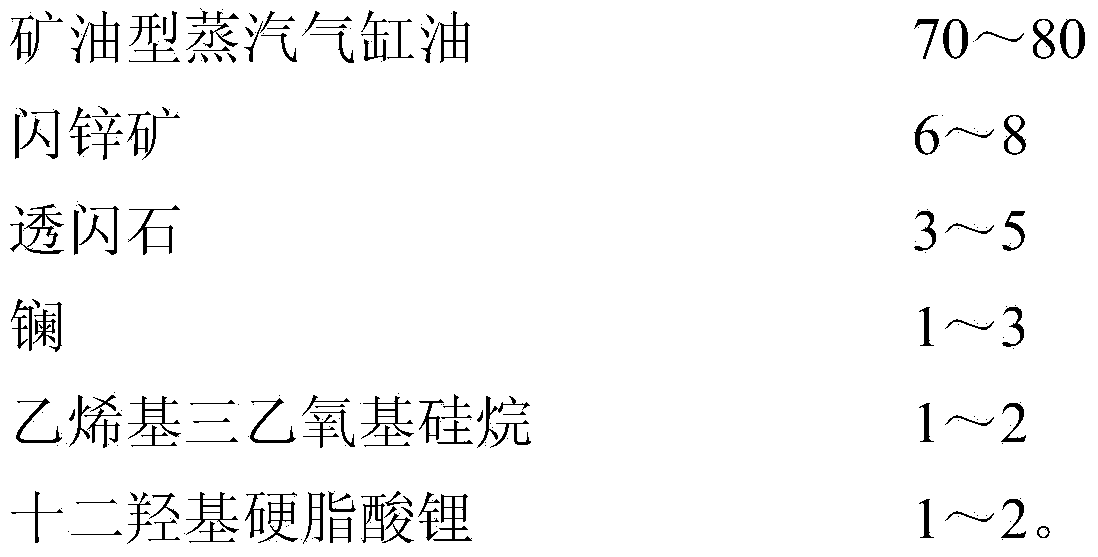

Embodiment 1

[0028] ① Grind sphalerite to a particle size of ≤5 μm and dry at 210°C for 2 hours; crush tremolite to a particle size of ≤200nm and dry at 110°C for 1 hour;

[0029] ②In parts by mass, weigh 70g of mineral oil-type steam cylinder oil obtained in step ①, 6g of sphalerite, 3g of tremolite, 1g of lanthanum, 1g of vinyltriethoxysilane, and 1g of lithium dodecyl hydroxystearate. Add it into the closed device to make the vacuum reach -0.08MPa;

[0030] ③Raise the temperature to 85°C, stir at 10000rpm for 30min, adjust the rotation speed to 18000rpm for 10min, and adjust the rotation speed to 28000rpm for 10min;

[0031] ④ Finely disperse in a 1KW ultrasonic generator for 30 minutes.

[0032] The prepared mineral oil-type steam cylinder oil composition was subjected to a wear test on a MMW-1 vertical universal friction and wear machine with a test force of 3000N and a rotational speed of 1000r / min. After 5 hours of wear test, the microhardness of the worn surface of the sample is ...

Embodiment 2

[0034] ① Grind sphalerite to a particle size of ≤5 μm and dry at 210°C for 2 hours; crush tremolite to a particle size of ≤200nm and dry at 110°C for 1 hour;

[0035] ②In parts by mass, weigh 75g of the mineral oil-type steam cylinder oil obtained in step ①, 7g of sphalerite, 4g of tremolite, 2g of lanthanum, 1.6g of vinyltriethoxysilane, and 1.3g of lithium dodecyl hydroxystearate. g mixed into the airtight device to make the vacuum reach -0.08MPa;

[0036] ③Raise the temperature to 85°C, stir at 10000rpm for 30min, adjust the rotation speed to 18000rpm for 10min, and adjust the rotation speed to 28000rpm for 10min;

[0037] ④ Finely disperse in a 1KW ultrasonic generator for 30 minutes.

[0038] The prepared mineral oil-type steam cylinder oil composition was subjected to a wear test on a MMW-1 vertical universal friction and wear machine with a test force of 3000N and a rotational speed of 1000r / min. After 5 hours of wear test, the microhardness of the wear surface of the...

Embodiment 3

[0040] ① Grind sphalerite to a particle size of ≤5 μm and dry at 210°C for 2 hours; crush tremolite to a particle size of ≤200nm and dry at 110°C for 1 hour;

[0041] ②Weigh 80g of mineral oil-type steam cylinder oil obtained in step ①, 8g of sphalerite, 5g of tremolite, 3g of lanthanum, 2g of vinyltriethoxysilane, and 2g of lithium dodecyl hydroxystearate in parts by mass. Add it into the closed device to make the vacuum reach -0.08MPa;

[0042] ③Raise the temperature to 85°C, stir at 10000rpm for 30min, adjust the rotation speed to 18000rpm for 10min, and adjust the rotation speed to 28000rpm for 10min;

[0043] ④ Finely disperse in a 1KW ultrasonic generator for 30 minutes.

[0044] The prepared mineral oil-type steam cylinder oil composition was subjected to a wear test on a MMW-1 vertical universal friction and wear machine with a test force of 3000N and a rotational speed of 1000r / min. After 5 hours of wear test, the microhardness of the worn surface of the sample is H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com