Large-scale microalgae separation, collection and drying equipment

A technology of drying equipment and microalgae, applied in the direction of biochemical equipment and methods, biochemical instruments, methods of supporting/immobilizing microorganisms, etc., to achieve the effects of continuous production, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

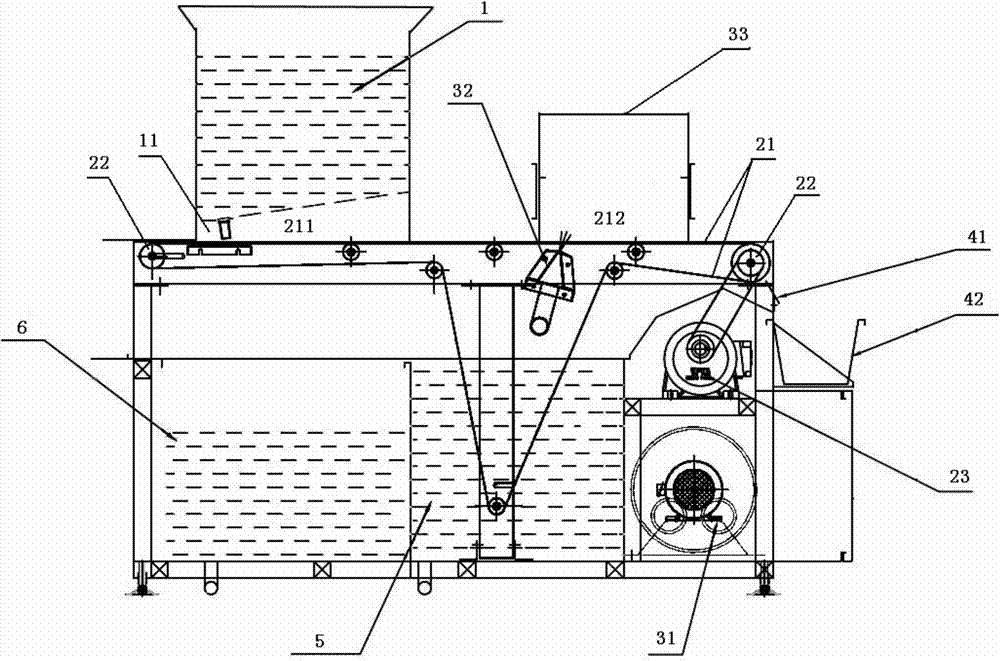

[0019] Such as figure 1 As shown, in a preferred embodiment of the present invention, the large-scale microalgae separation, collection and drying equipment includes a feed hopper, a material conveying system, a blast heating system, a collection device and a filter belt cleaning tank.

[0020] The flocculation-sedimented microalgae culture solution is placed in the feeding hopper 1 . The material conveying system consists of a filter belt 21 , a plurality of rollers 22 and a motor 23 . The porosity of the filter belt is 0.1mm. The filter belt 21 is arranged in an annular shape and is driven by a plurality of rollers 22 , one of which is connected with a motor 23 . The blast heating system is made up of blast heater 31, wind knife 32 and wind cover 33. The collection device consists of a scraper 41 and a collection bucket 42 .

[0021] The top of the annular filter belt 21 is horizontally arranged as a working area, and the bottom of the ring is a cleaning area. One end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com