Construction method of post-cast strip area and floor area supporting systems on two sides of post-cast strip area

A technology of support system and construction method, applied in the processing of building materials, formwork/template/work frame, and on-site preparation of building components, etc., can solve the problems of reducing structural safety and durability, and achieve no welding light. The effect of air pollution, high recycling rate and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

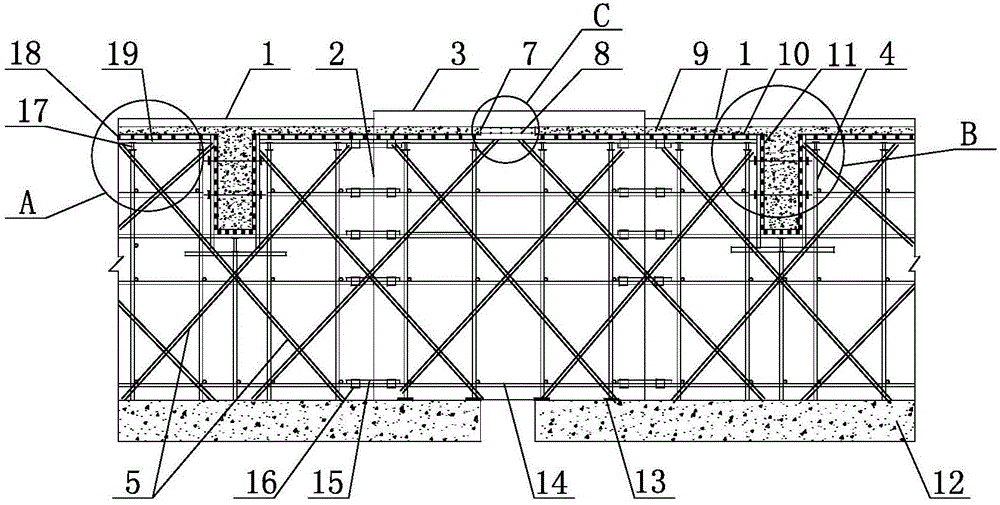

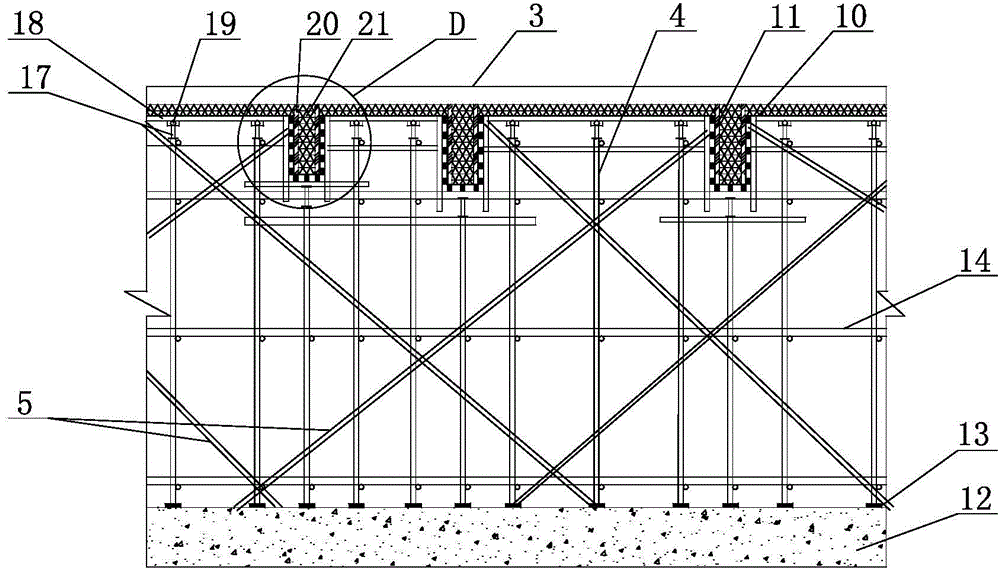

[0030] The present invention will be further described below in conjunction with the drawings:

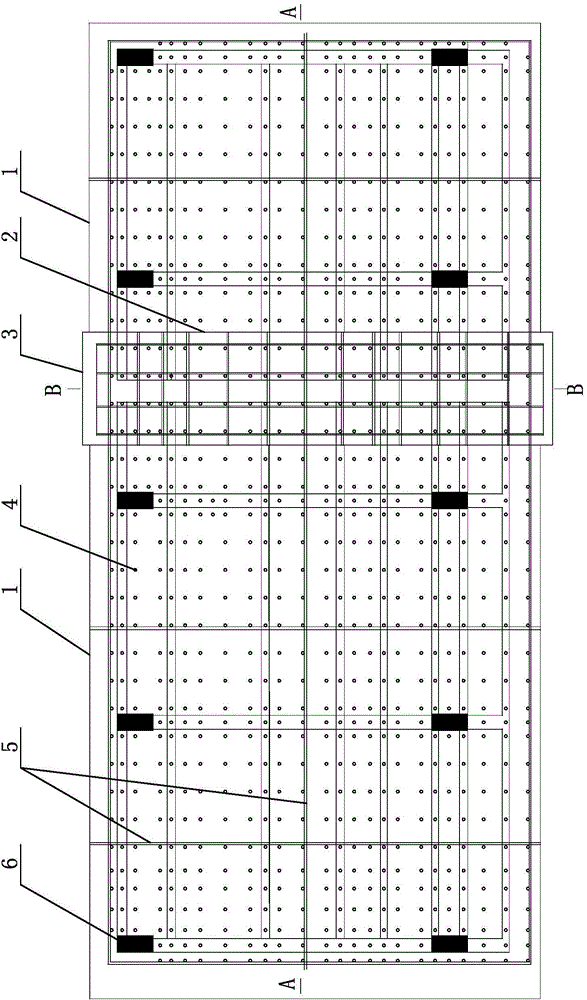

[0031] Such as Figure 1 ~ Figure 7 As shown, the construction method of the post-cast zone area and the floor area support system on both sides of the present invention is characterized in that the following steps are taken:

[0032] 1) Positioning and laying line: The position lines of the post-cast zone support system 3 and the pole 4 of the floor support system 1 on the foundation raft 12 according to the distance between the vertical and horizontal distances of 600-900mm;

[0033] 2) Set up poles: lay the steel pad 13 under the pole 4 of the post-cast zone regional support system 3, and simultaneously place the post-cast zone regional support system 3 and the pole 4 of the floor zone support system 1 in place;

[0034] 3) Erection of horizontal rods: according to the post-cast zone support system 3 and floor area support system 1, the frame column 6 and the horizontal rod 14 are respe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap