Bipolar two-dimensional fully flexible high-precision servo platform

A servo platform, fully flexible technology, applied in the direction of machine/support, supporting machine, mechanical equipment, etc., can solve the problems of hinge fatigue damage, flexible hinge stress increase, etc., to achieve no cumulative error, reduce coupling motion, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the following will combine the accompanying drawings of the embodiments of the present invention, and on the basis of considering factors such as platform structure optimization and manufacturing process, to analyze the technical aspects of the embodiments of the present invention The program is clearly and completely described. Of course, the embodiments described with reference to the drawings are exemplary, and are intended to explain the present invention, and should not be construed as limiting the present invention.

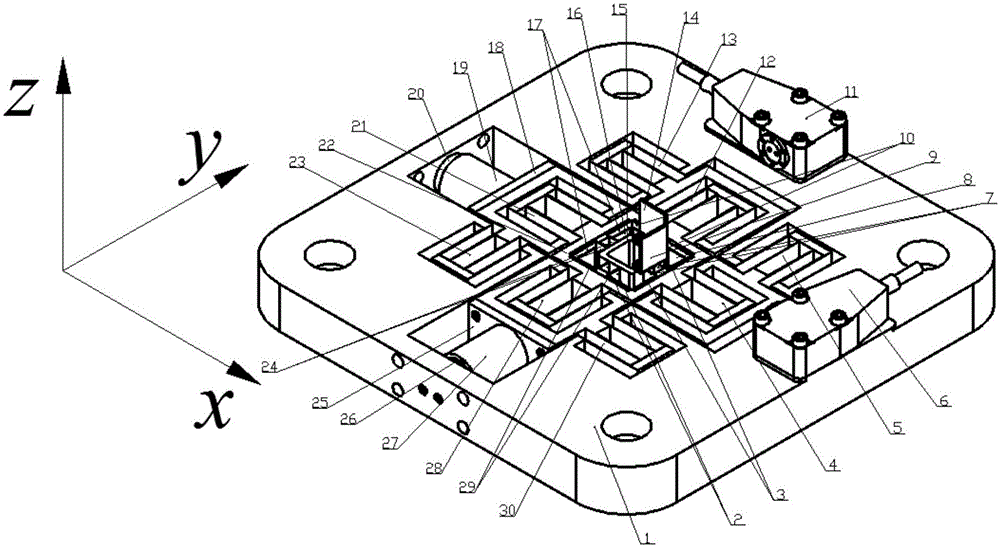

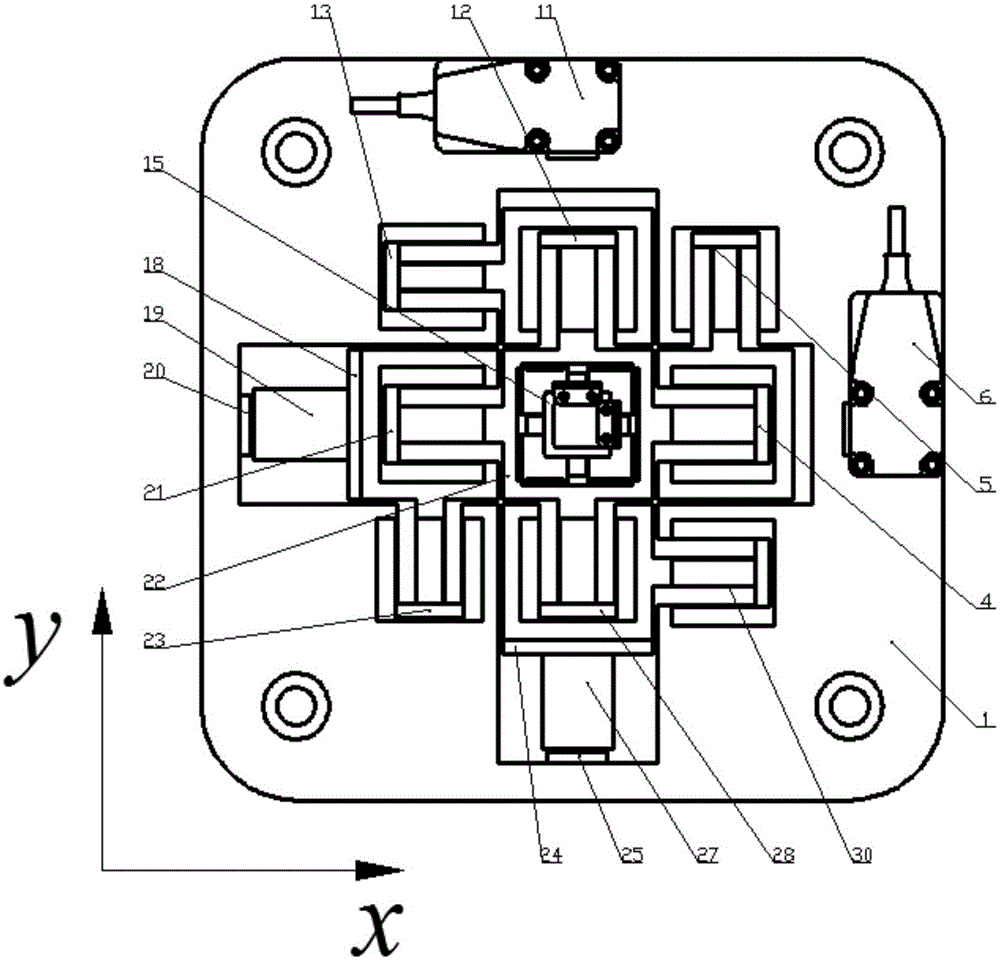

[0044] figure 1 It is a schematic diagram of the three-dimensional structure of an embodiment of the present invention. It can be clearly seen from the figure that the present invention adopts a series structure as a whole, and consists of a micro-motion platform embedded in the center of a macro-motion platform.

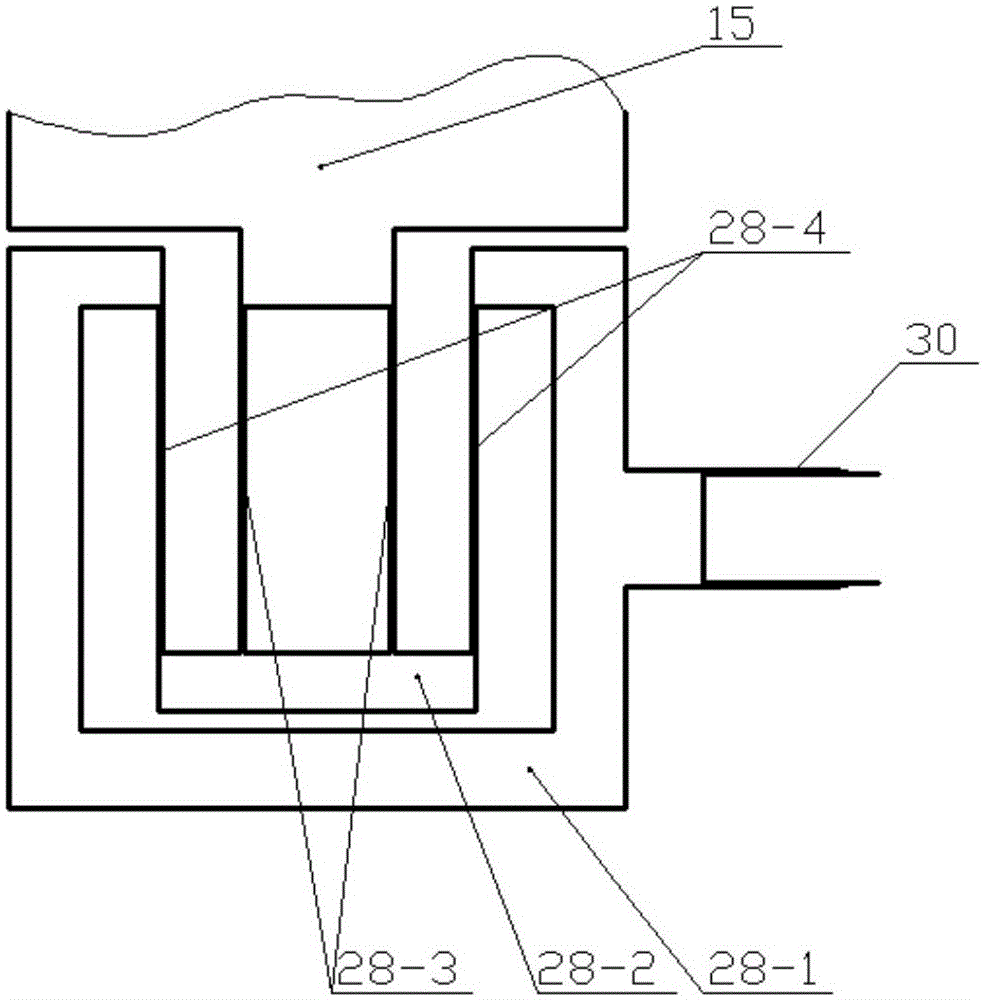

[0045] The macr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com