Box type high-voltage heater

A technology of high-pressure heaters and headers, which is applied in the direction of feed water heaters, heat exchanger types, heat exchanger shells, etc., can solve the problems of inconvenient production, high quality risk, inability to adapt to variable load operation and peak shaving operation, etc. Achieve the effects of shortening the construction period, ensuring safe operation, and avoiding the risk of deformation due to temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

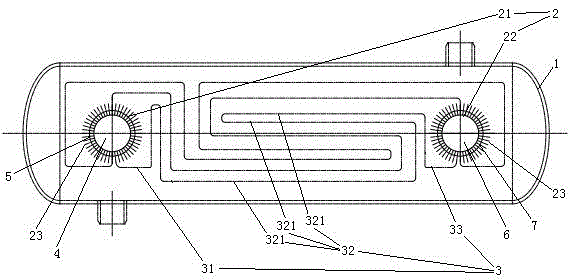

[0022] Embodiment one, see figure 1 , a header-type high-pressure heater, including a shell 1, a pair of headers 2 and a number of heat exchange tubes 3.

[0023] The shell 1 is a horizontal structure. Of course vertical structures are also possible.

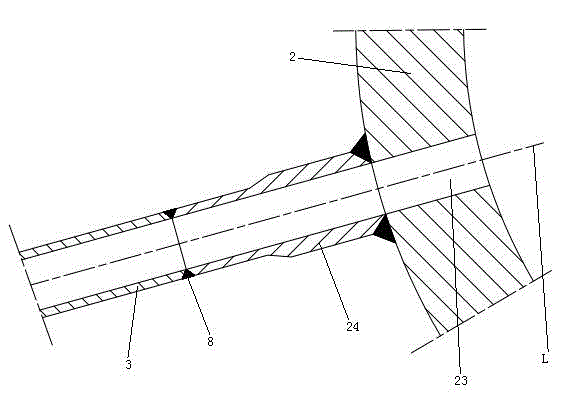

[0024] The header 2 is cylindrical. The two headers in the pair of headers 2 are the water inlet header 21 and the water outlet header 22 respectively. A pair of headers 2 are located inside the casing 1 . Two of the pair of headers 2 are distributed at both ends of the casing 1 along the axial direction. The wall thickness of the header box 2 is 80 mm (calculated according to the material, the thickness of different materials is different, in this embodiment, it is the thickness when the same material as the existing tube sheet is used). A water hole 23 is provided on the peripheral wall of the header box 2 . The number of water holes 23 on each header 2 is about 2100 (according to the calculation of the diameter of the h...

Embodiment 2

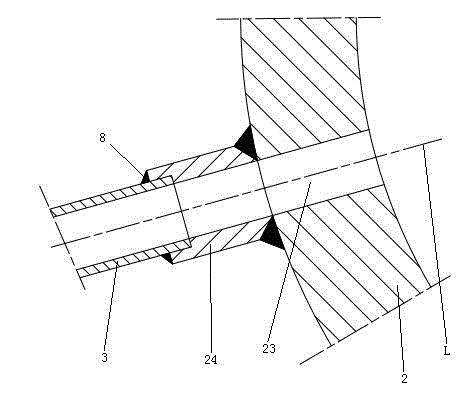

[0028] Embodiment two, see image 3 , the difference from the first embodiment is: the end of the heat exchange tube 3 is plugged into the tube base 24 . Weld 8 is a fillet weld.

Embodiment 3

[0029] Embodiment three, see Figure 4 , the difference from the first embodiment is: the end of the heat exchange tube 3 is plugged into the water hole 23 . The heat exchange tube 8 and the header 2 are welded together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com