Testing device for smashing seafloor rock

A test device and rock technology, applied in the field of underwater rock crushing, can solve the problems of the reliability and accuracy of the rock crushing test device, the inability to obtain the rock crushing performance parameters of the seabed, and affect the safety and operability of the device, so as to achieve reliable Improved performance, easy operation, and guaranteed safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

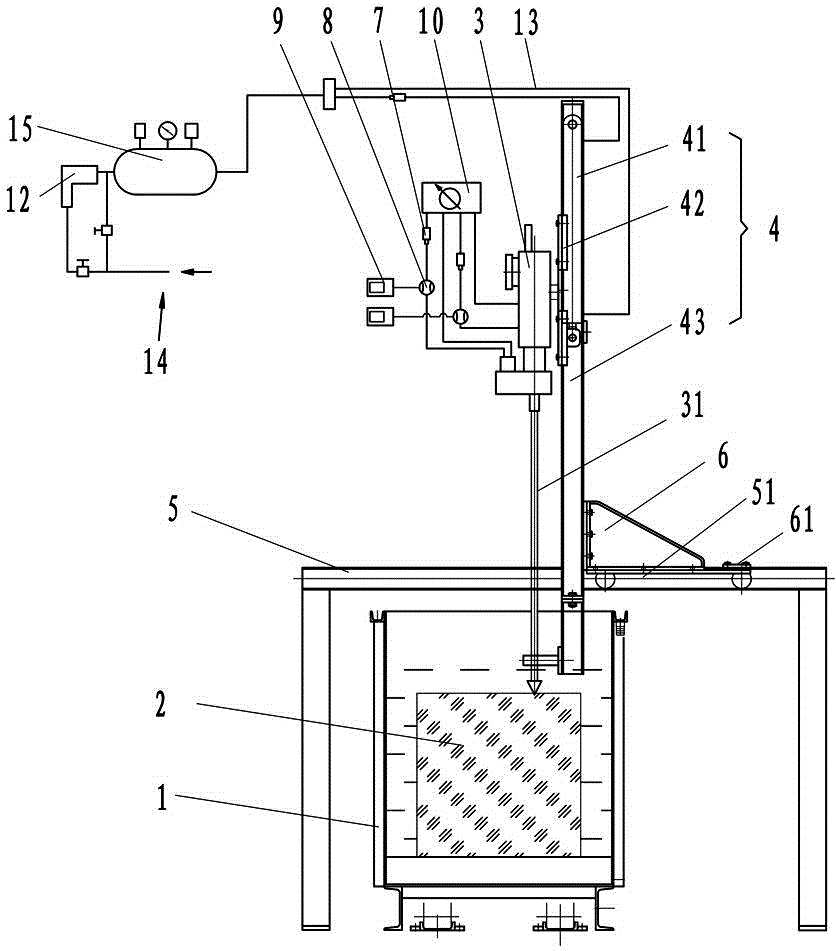

[0022] figure 1 Shown is the embodiment of a kind of test device that is used for seabed rock fragmentation of the present invention, comprises rotary impact mechanism and is used for simulating the test chamber 1 of seabed rock environment, is full of liquid and rock 2 to be tested in the test chamber 1 The rotary punching mechanism includes a rotary punching drill 31 , a rotary drive assembly and a displacement drive assembly 4 for driving the rotary punch 31 into the test box 1 to break the rock 2 . The present invention realizes the simulation of the real situation of seabed rock crushing through the test box 1 simulating the seabed rock environment, ensures the accuracy of rock crushing performance parameters in the seabed environment, and improves the reliability of the test device; The drill bit 31 is located in the water environment when crushing stones, so that the control mechanism of the rotary puncher 3 does not have the problem of water ingress, ensuring the safet...

Embodiment 2

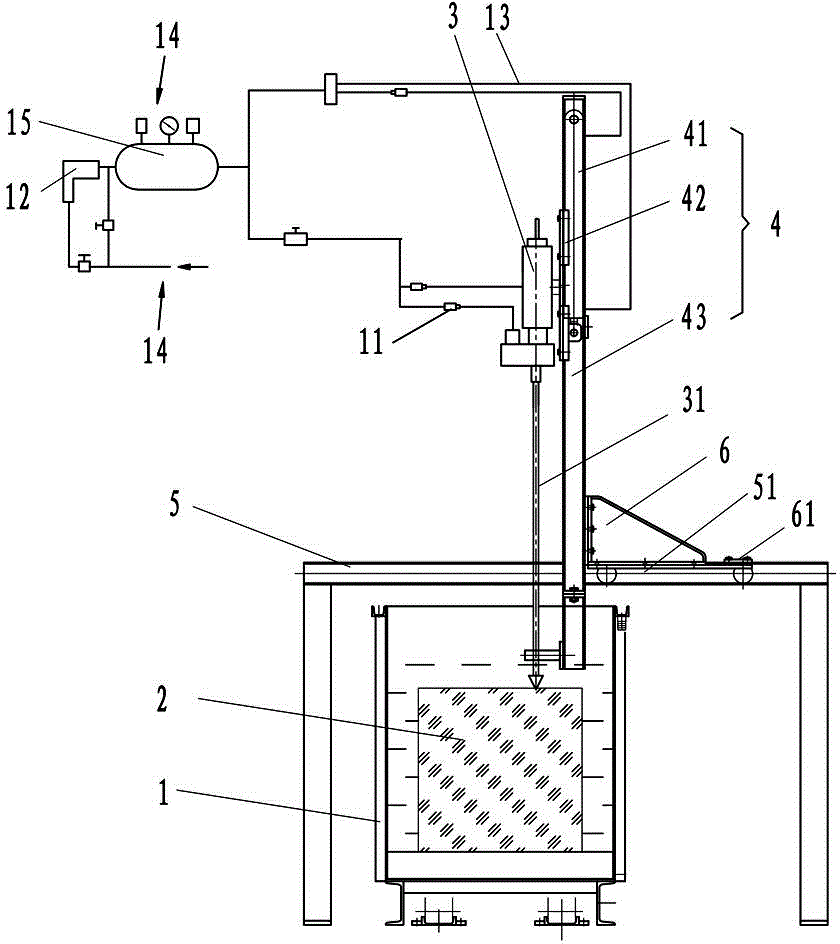

[0030] figure 2 Shown is another embodiment of the test device for seabed rock fragmentation of the present invention, this embodiment is basically the same as the previous embodiment, the difference is that the swirl 3 of this embodiment is a pneumatic swirl; The punching device is connected with a compressed gas source 14, and between the pneumatic rotary punching device and the compressed gas source 14, an air pressure sensor 11 for detecting the pressure of the incoming and returning air, a gas flow meter 12 for detecting the flow rate of the incoming and returning air, and a gas flow meter for storing the A gas tank truck 15 for a source 14 of compressed gas is described.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com