Electronic-control permanent magnetic field generator and applying method in magnetism grain finishing process

A magnetic field generating device and electronically controlled permanent magnet technology, which is applied in the direction of magnetic objects, circuits, electrical components, etc., can solve the problems of difficult demagnetization and high energy consumption of permanent magnet sources, and achieve ingenious structure, low energy consumption, and enhanced magnetic induction intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

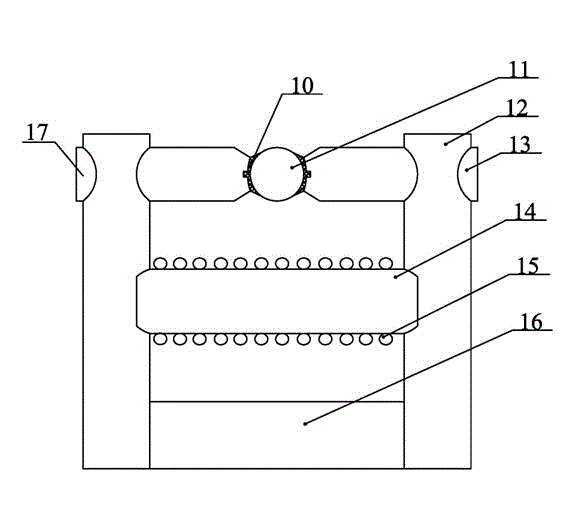

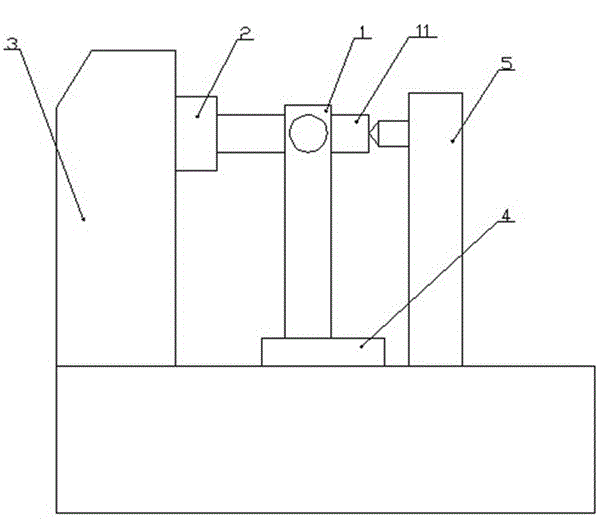

[0011] The electronically controlled permanent magnet magnetic field generating device in the magnetic abrasive finishing process includes a main magnet 16 with a rectangular cross section, the main magnet 16 is made of NdFeB (N35), and the long and short sides of the cross section of the main magnet 16 are The length of each side is 80mm, the length of the main magnet 16 is 100mm, the magnetization direction of the main magnet 16 is horizontal to the left, and a cylindrical reversible magnet 14 is arranged side by side above the main magnet 16. The reversible magnet 14 is made of AlNiCo LNG52, Its diameter is 60mm, and its length is 200mm. The magnetization direction of the reversible magnet is horizontal to the left. The reversible magnet 14 is wound and fixed with a coil 15. The number of turns of the coil 15 is 5000 turns. The excitation current of the coil 15 is 5A. The reversible magnet 14 and The main magnet 16 is fixed on the yoke 12 provided at the left and right ends,...

Embodiment approach 2

[0013] The electronically controlled permanent magnet magnetic field generating device in the magnetic abrasive finishing process includes a main magnet 16 with a rectangular cross section, the main magnet 16 is made of NdFeB (N35), and the long and short sides of the cross section of the main magnet 16 are The length of each side is 50 mm, the length of the main magnet 16 is 38 mm, the magnetization direction of the main magnet 16 is horizontal to the left, and a cylindrical reversible magnet 14 is arranged side by side above the main magnet 16. The reversible magnet 14 is made of AlNiCo LNG52, The diameter is 40mm, the length is 100mm, the magnetization direction of the reversible magnet is horizontal to the left, the reversible magnet 14 is wound and fixed with a coil 15, the number of turns of the coil 15 is 1000 turns, the excitation current of the coil 15 is 5A, the reversible magnet 14 and The main magnet 16 is fixed on the yoke 12 provided at the left and right ends, an...

Embodiment approach 3

[0015] The electronically controlled permanent magnet magnetic field generating device in the magnetic abrasive finishing process includes a main magnet 16 with a rectangular cross section, the main magnet 16 is made of NdFeB (N35), and the long and short sides of the cross section of the main magnet 16 are The length of each side is 60mm, the length of the main magnet 16 is 68mm, the magnetization direction of the main magnet 16 is horizontal to the left, and a cylindrical reversible magnet 14 is arranged side by side above the main magnet 16. The reversible magnet 14 is made of AlNiCo LNG52, The diameter is 50mm, the length is 150mm, the magnetization direction of the reversible magnet is horizontal to the left, the reversible magnet 14 is wound and fixed with a coil 15, the number of turns of the coil 15 is 2000 turns, the excitation current of the coil 15 is 5A, the reversible magnet 14 and The main magnet 16 is fixed on the yoke 12 provided at the left and right ends, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap