A kind of preparation method of li4ti5o12/c composite material

A technology of composite materials and ball milling, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of complex process and high cost, and achieve the effect of simple preparation process, low cost, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

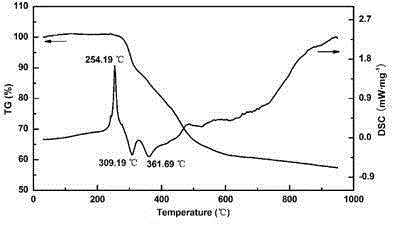

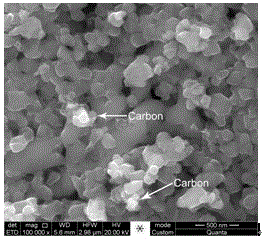

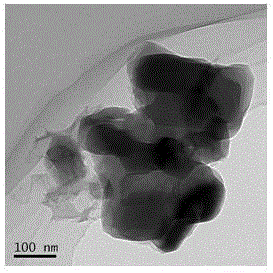

Image

Examples

Embodiment 1

[0042] A kind of Li 4 Ti 5 o 12 The preparation method of / C composite material comprises the steps:

[0043] (1) Li 4 Ti 5 o 12 / C composite material precursor preparation:

[0044] Add 2.131g of titanium dioxide as the titanium source, 2.050g of lithium lactate as the lithium source and carbon source in the ball milling tank, add the dispersant and then carry out ball milling. During the ball milling process, rotate forwards and reverses alternately every 1h, and ball mill and mix at a speed of 450r / min for 6h Afterwards, the resulting mixture was placed in an oven at 60°C for 3 hours to obtain Li 4 Ti 5 o 12 / C composite material precursor;

[0045] Wherein, the amount of the dispersant added is subject to being able to submerge the powdery material, so that the dispersant can form a viscous slurry with the powdery material, so that the ball milling and mixing of the material is more uniform.

[0046] (2) Li 4 Ti 5 o 12 / C composite preparation:

[0047] Under...

Embodiment 2

[0052] A kind of Li 4 Ti 5 o 12 The preparation method of / C composite material comprises the steps:

[0053] (1) Li 4 Ti 5 o 12 / C composite material precursor preparation:

[0054] Add 4.1802g of titanium dioxide as the titanium source and 4.2273g of lithium stearate as the lithium source and carbon source in the ball milling tank. After adding the dispersant, ball milling is carried out. During the ball milling process, the positive and negative rotations are alternately rotated every 1h, and the ball milling speed is 450r / min. After mixing for 6 hours, the resulting mixture was kept in an oven at 60°C for 3 hours to obtain Li 4 Ti 5 o 12 / C composite material precursor;

[0055] The amount of dispersant added is based on the ability to submerge the powdery material, so that the dispersant can form a viscous slurry with the powdery material, making the ball milling of the material more uniform.

[0056] (2) Li 4 Ti 5 o 12 / C composite preparation:

[0057] Und...

Embodiment 3

[0061] A kind of Li 4 Ti 5 o 12 The preparation method of / C composite material comprises the steps:

[0062] (1) Li 4 Ti 5 o 12 / C composite material precursor preparation:

[0063] Add 10.3285g of titanium dioxide as the titanium source, 7.4581g of lithium lactate and 7.5126g of lithium stearate as the lithium source and carbon source in the ball milling tank. After adding the dispersant, carry out ball milling. After ball milling and mixing for 6 hours at a rotational speed of 450r / min, the resulting mixture was placed in an oven and kept at 60°C for 5 hours to obtain Li 4 Ti 5 o 12 / C composite material precursor;

[0064] The amount of dispersant added is based on the ability to submerge the powdery material, so that the dispersant can form a viscous slurry with the powdery material, making the ball milling of the material more uniform.

[0065] (2) Li 4 Ti 5 o 12 / C composite preparation:

[0066] Under an argon atmosphere, the Li obtained in step (1) 4 Ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com