Assembly comprising edible-oil cleaning agent and container, and purification method of edible-oil using same

An edible oil and combination technology, which is applied in the directions of edible oil/fat, chemical instruments and methods, separation methods, etc., to achieve the effects of reducing waste oil discharge, improving on-site environment, and reducing purchase costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

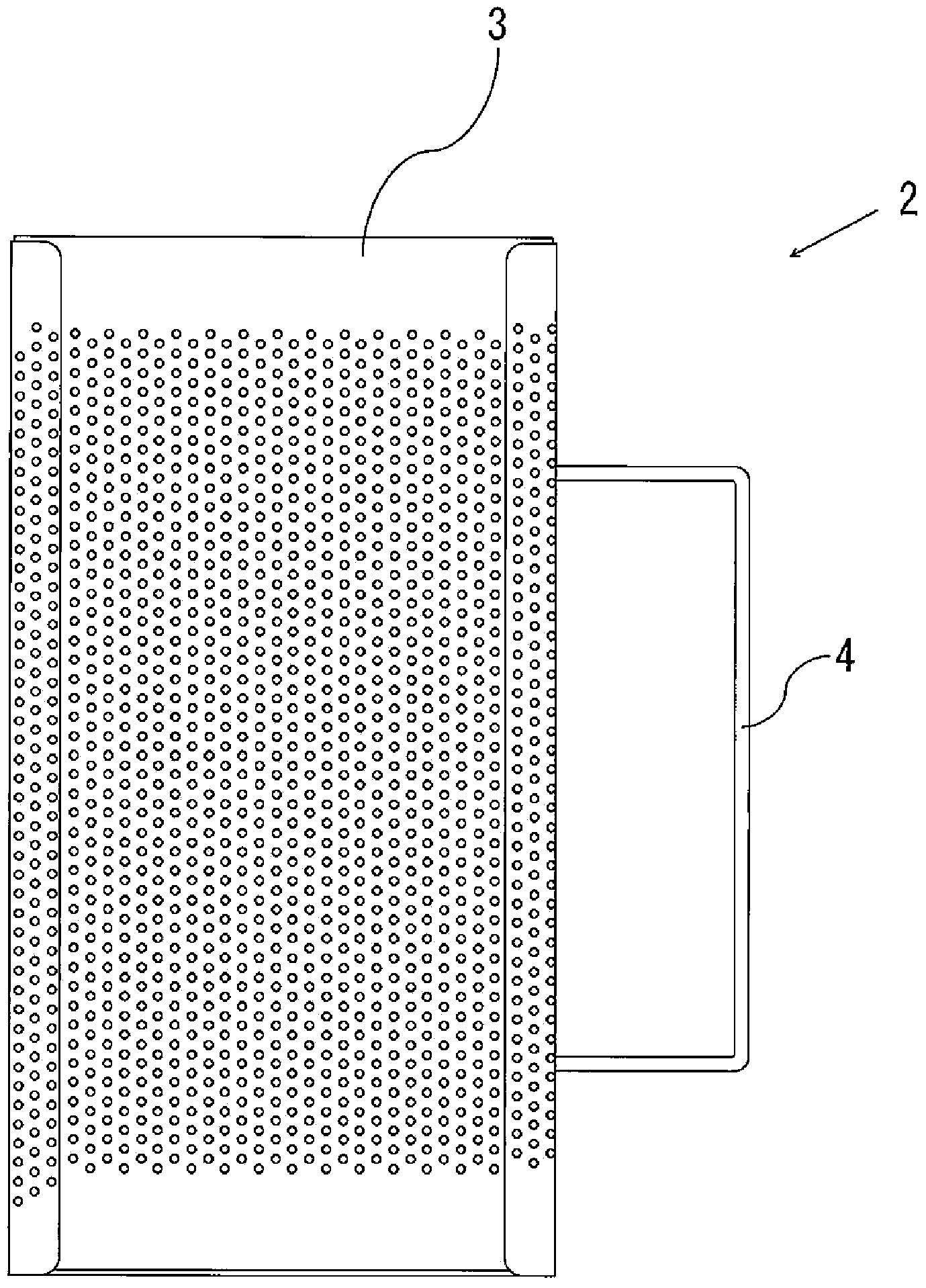

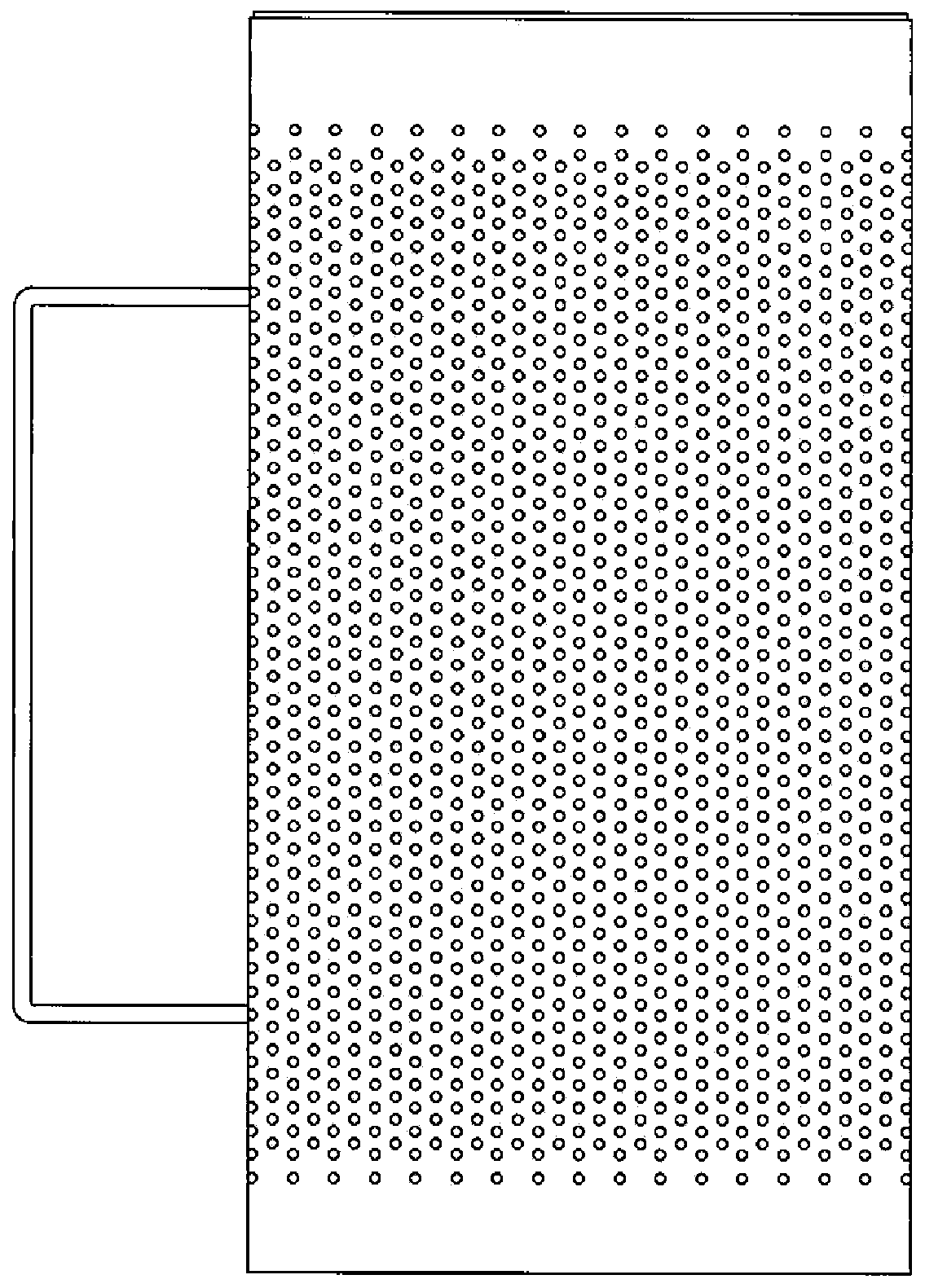

[0106] Put 40 g of magnesium oxide particles for food additives (77.0% in the range of 500-180 μm in particle size, 22.4% in the range of 180-106 μm in particle size) into bags made of copolymerized polyethylene terephthalate 7.7× 12cm rectangular bag and sealed. On the other hand, a container containing 18 L of unused soybean oil was prepared, and 1 bag of magnesium oxide (40 g ), put 1 bag in a stainless steel container (300 g, width 16×length 8×thickness 1.5 cm), and fix one stainless steel container near a heat source in soybean oil.

[0107]We heat soybean oil and fry potatoes for French fries for 10 hours a day while always maintaining a temperature of 170°C. On the seventh day, the bag of the detergent was taken out, replaced with a new bag, and the same operation was continued. At the end of each day's frying, the acid value and polar compounds of soybean oil were determined, and the purification status of the oil was discussed. After the soybean oil was used for on...

Embodiment 2

[0118] In this example, a purification test of rapeseed oil was performed in the same manner as in Example 1. The results are shown in Table 3. The acid value of edible oil was 2.5, which became the limit value after 15 days, and the amount of polar compounds was 11 after 16 days, which was lower than the limit value. It is clear that the edible oil detergent of the present invention is also effective for rapeseed oil.

[0119] [table 3]

[0120] Elapsed days

Embodiment 3

[0122] The deterioration test of soybean oil was carried out under the same conditions as in Example 1 except that the magnesia was made into porous magnesia. The production of porous magnesia was carried out according to the following procedure. That is, magnesium oxide particles with a particle size of 82.0% in the range of 500 to 180 μm and 17.5% in the range of 180 to 106 μm were pressed using a press (BRIQETTING PRESS BRE-32, manufactured by Maekawa Laboratory Works) under a pressure of 10 MPa. A plate shaped product is obtained. This was fired at 1200° C. for 4 hours to obtain a porous molded body. This was pulverized, classified, and granulated to obtain porous magnesium oxide with a particle diameter of 500 to 180 μm of 79.0% and a particle size of 180 to 106 μm of 20.1%.

[0123] From this test, it became clear that when the result similar to Example 1 was obtained and compared with a comparative test, this invention can manufacture fried food over 5 to 7 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com