Hall-effect thruster

A Hall effect and thruster technology, applied in the field of plasma thrusters, can solve problems such as limiting the life of thrusters, decreasing engine efficiency, and accelerating engine aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

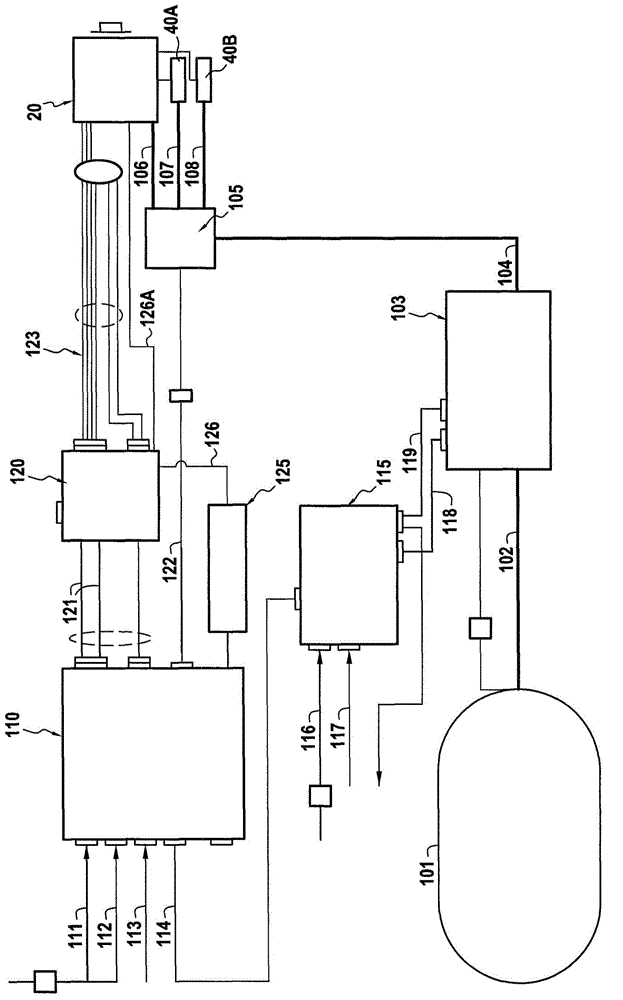

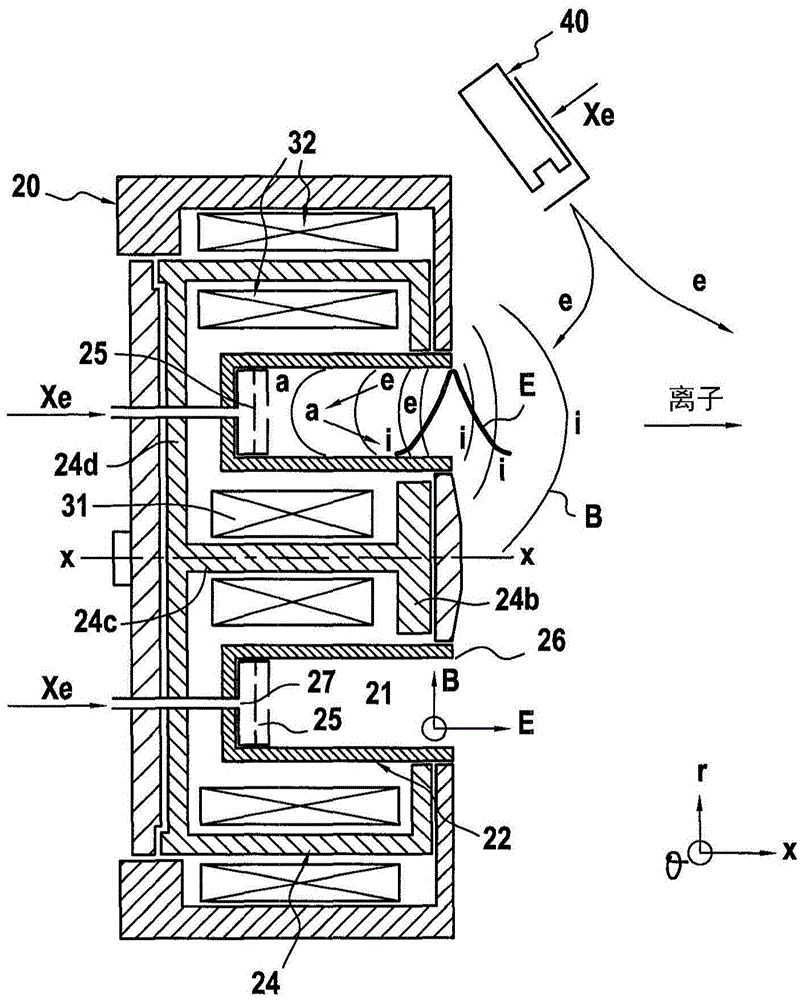

[0028] The present invention relates to the above referenced figure 2 The general structure of the Hall effect thruster is described.

[0029] Although often referred to as "stationary plasma thrusters," conventional Hall-effect thrusters are unstable in operation. Several frequency ranges in the range of 20 kilohertz (kHz) to several gigahertz can be considered.

[0030] At low frequencies, conventional Hall effect thrusters are characterized primarily by the following phases:

[0031] a) filling the discharge channels with inert atoms of propellants such as xenon;

[0032] b) ionize the inert atoms with energetic electrons in the lower half of the thruster; and

[0033] c) The ions that have been produced are accelerated and ejected by means of an electric field E proportional to the discharge voltage Ud of the thruster.

[0034] The same three-stage loop restarts periodically.

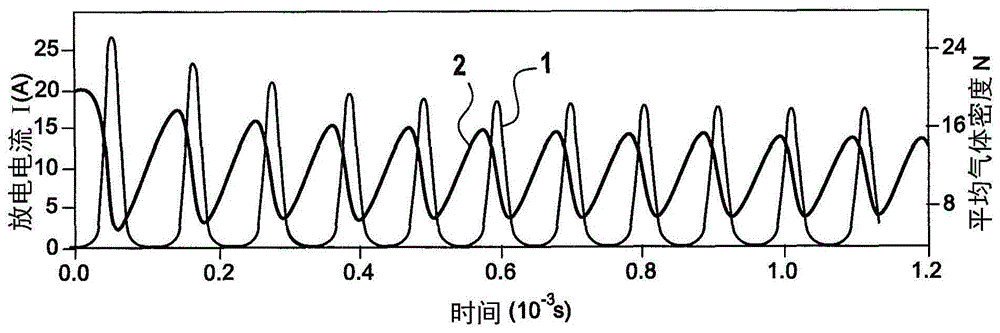

[0035] image 3 A simplified model showing vibrations in a Hall effect thruster.

[0036]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com