Die-casting device for solving air hole defect of die-casting product and die-casting process thereof

A porosity and defect technology, applied in the field of die-casting devices, can solve the problems of incomplete vacuuming, easy entry of molten liquid into the vacuum valve, influence of normal operation of product die-casting quality equipment, etc., to achieve good mechanical properties, smooth surface and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

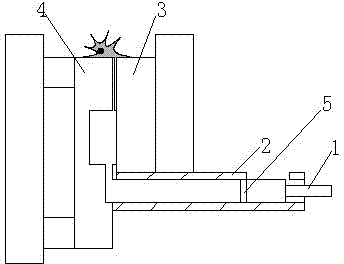

[0039] The present invention comprises a die-casting machine and a vacuum device. A punch 1 and a feeding port corresponding to the barrel 2 are arranged on the barrel 2 of the die-casting machine. A movable mold 4 and a static mold 3 are arranged at the rear end of the barrel 2. 4. A mold cavity is formed between the static molds 3, a vacuum valve is provided at the end of the mold cavity and a control device for controlling the closing of the vacuum valve is provided; a piston ring 5 is provided at the end of the punch 1, and the piston ring 5 and the inner wall of the barrel 2 correspond.

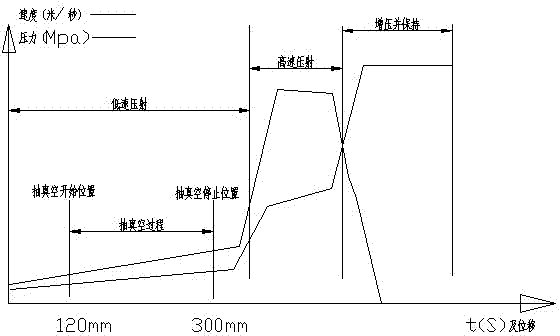

[0040] The engineering process of the die-casting device of the present invention is specifically as follows: rapidly filling the cavity of the mold with the molten alloy liquid under the action of high speed, and crystallizing, solidifying and forming the alloy liquid under the action of high pressure. When the soup feeder pours the molten alloy liquid into the barrel 2, the plunger pun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com