Blade for etching glass substrate

A technology of glass substrates and blades, applied in optics, instruments, electrical components, etc., can solve the problems of glass substrate spots or uneven thickness, uneven distribution of etching solution, changes in etching solution, etc., to achieve convenient operation, shortening and thinning Process operation time, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] specific implementation plan

[0026] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

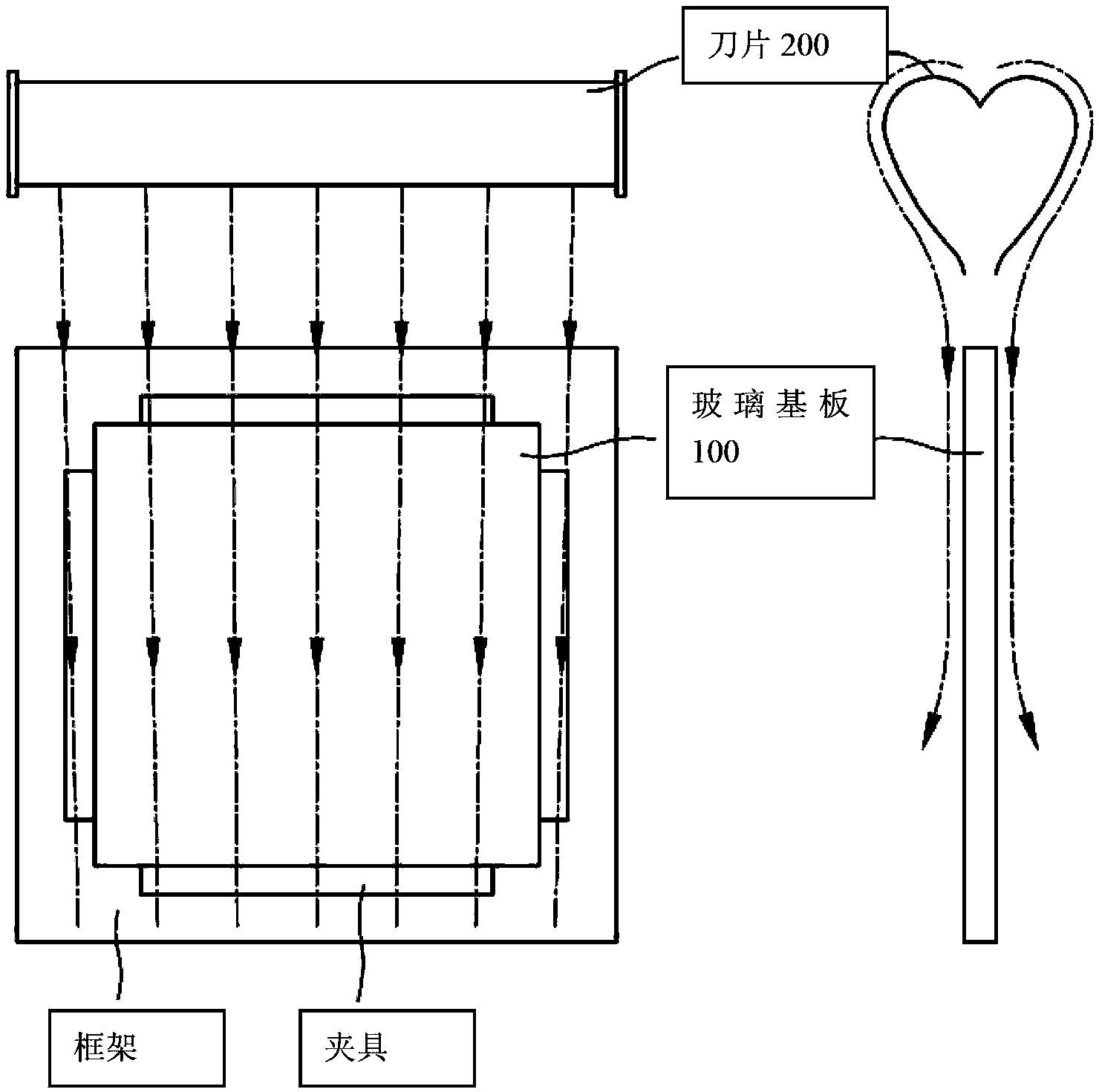

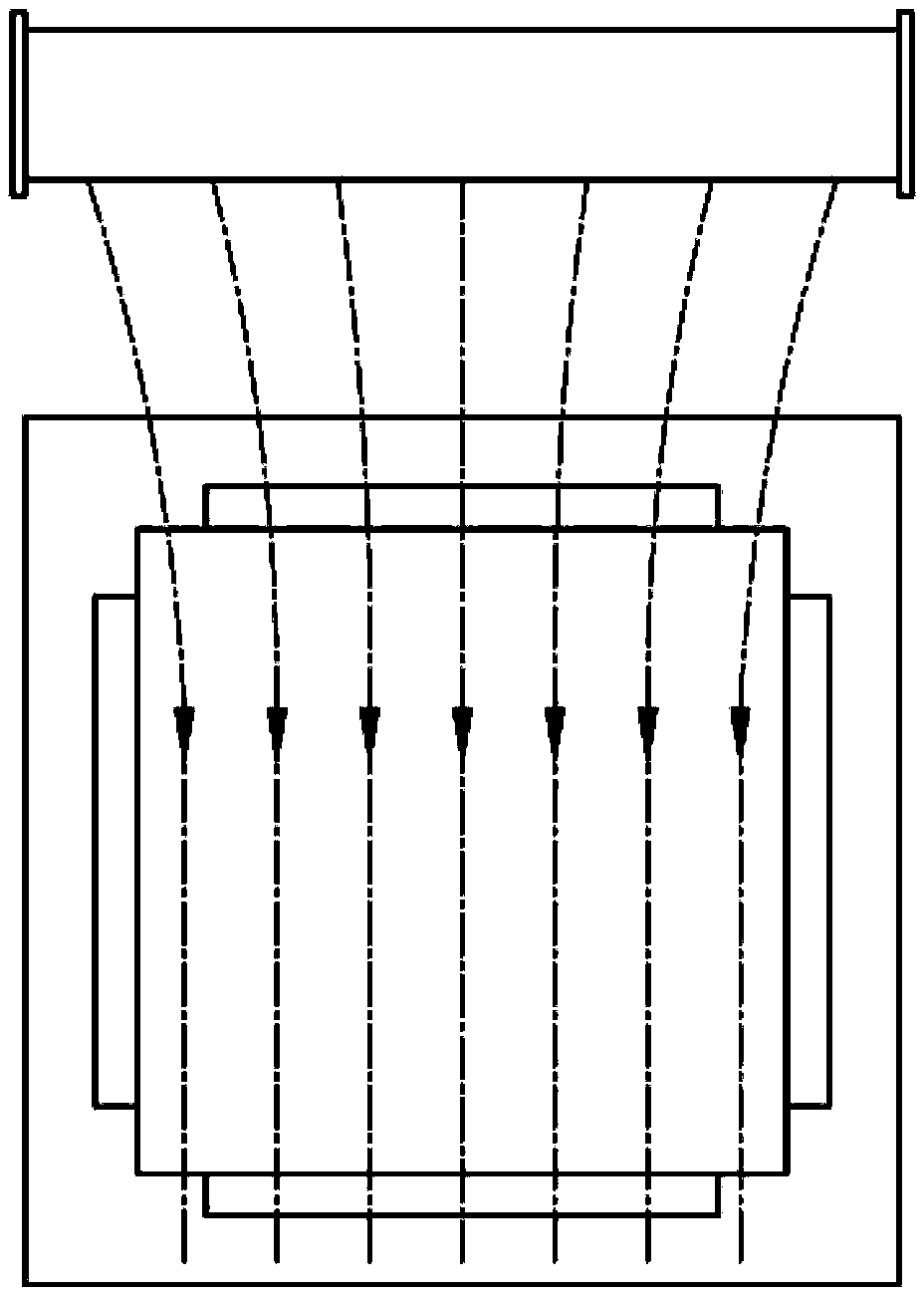

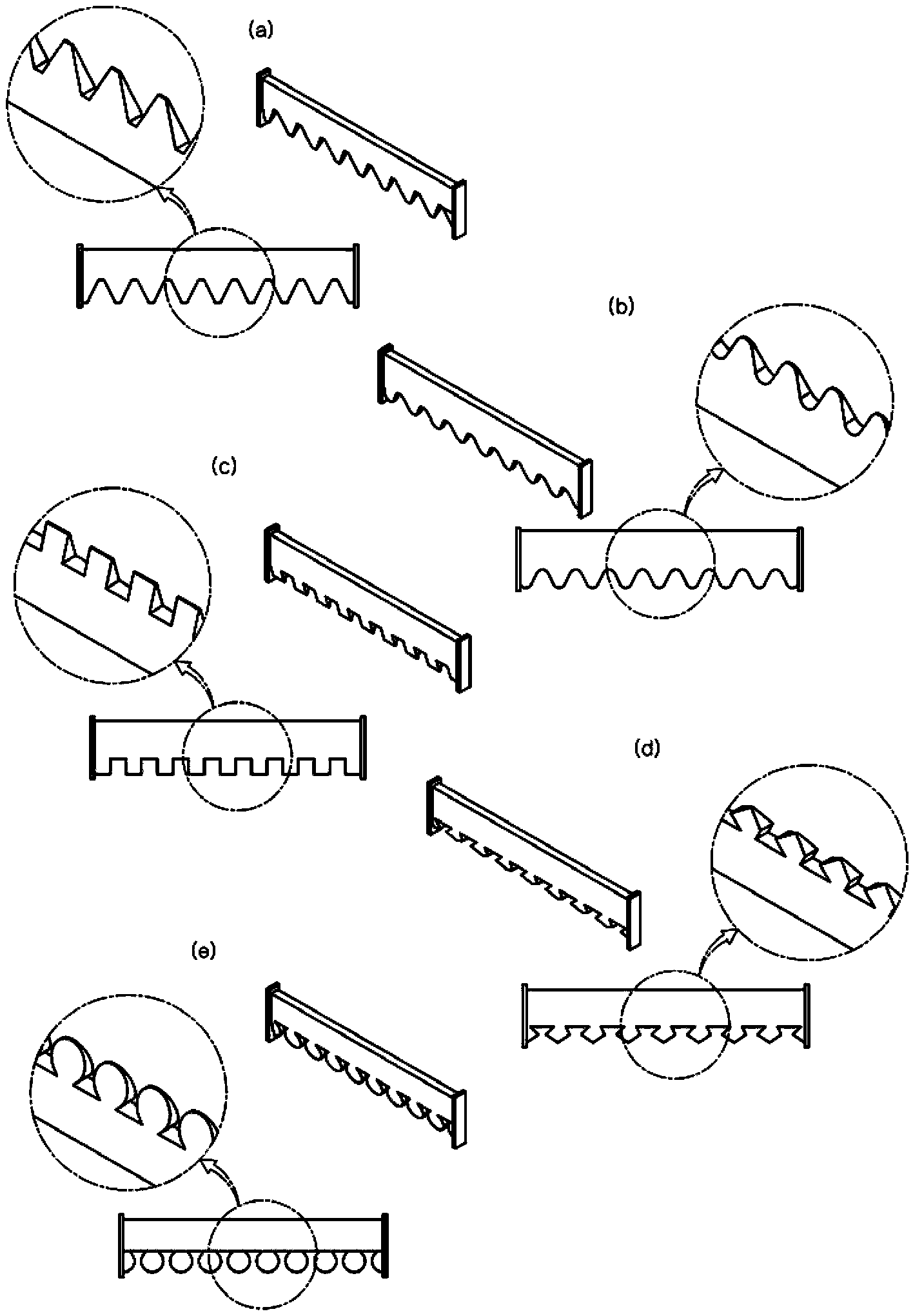

[0027] Such as image 3 As shown, the vertical flow glass substrate etching blade 200 is made into a curved shape at its end. That is, the end portion of the blade is formed by shapes such as corrugated shape, zigzag shape, four-corner concave-convex, diamond-shaped concave-convex, circular concave-convex and the like. Such as figure 1 sectional view of and image 3 As shown in the sectional view of , the thickness of the blade becomes thinner toward the end, and the etching solution flows down along the outer peripheral surface of the blade. And, the inside of the blade can be made into a hollow space, a slit for the inflow of the etching solution is provided at the upper end, and a hole (hole) or a crack is formed at the curved end. At this time, the etching solution can not only flow down thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap