Preparation method for carboxyethyl welan gum

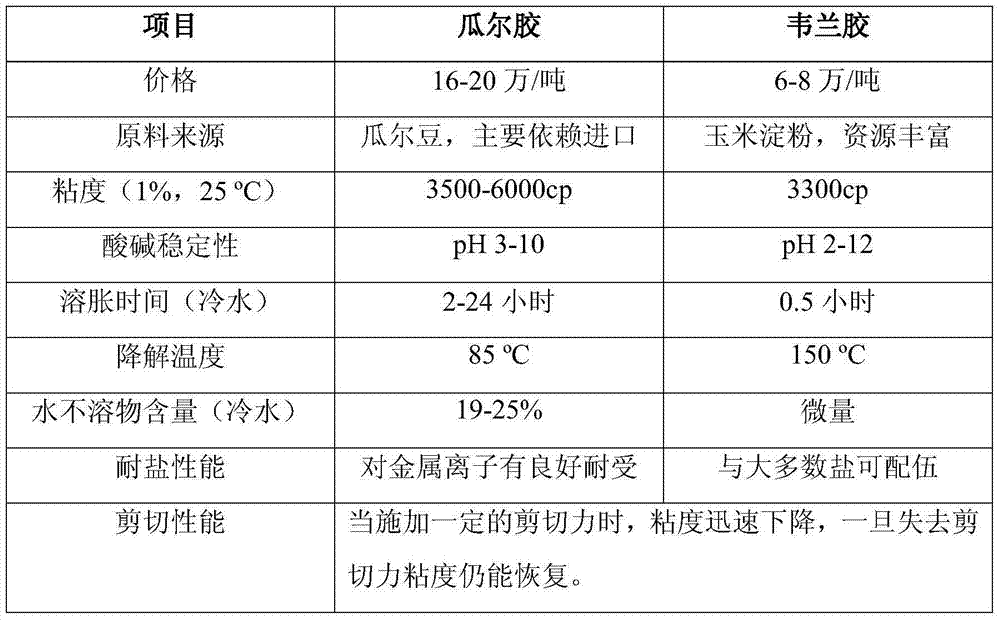

A technology of carboxyethyl Welan gum and Welan gum, which is applied in the field of modification of microbial polysaccharides, can solve the problems of slow dissolution rate, high content of water-insoluble matter, poor thickening ability, etc., and achieve easy acquisition and improved dissolution time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

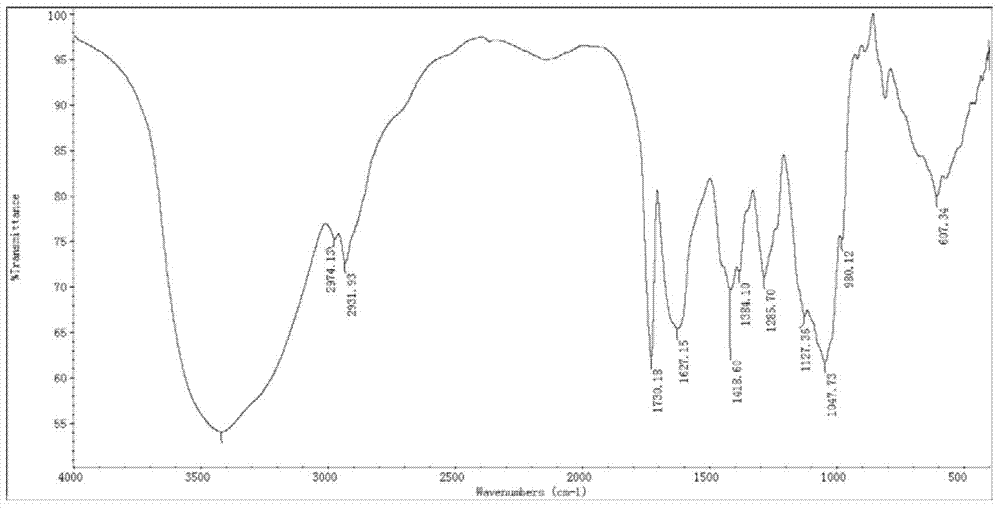

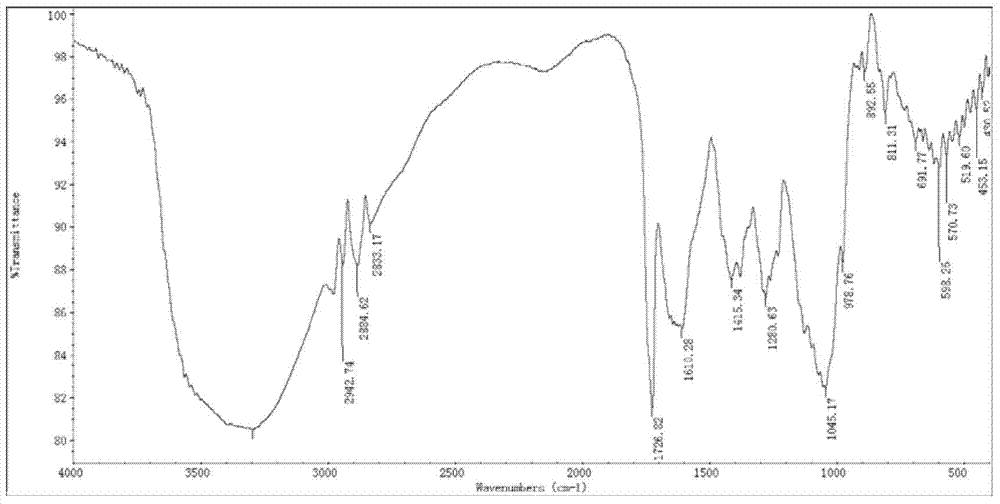

Image

Examples

Embodiment 1

[0024] In a three-necked flask, take Welan gum and dissolve it in water to form an aqueous solution with a concentration of 0.002mol / L, and stir at a speed of 450rpm to allow it to fully dissolve; in the solution prepared by 3-chloropropionic acid and potassium acetate, , the concentration of 3-chloropropionic acid is 0.004mol / L, the concentration of potassium acetate is 0.004mol / L, and the molar ratio of Velan Gum:3-chloropropionic acid is controlled to be 1:1; within 10~60min, 3- The solution of chloropropionic acid and potassium acetate was added dropwise at a constant speed; reacted at normal pressure, 60°C, and stirred for 1 hour, collected the reaction solution, poured it into absolute ethanol to precipitate carboxyethyl Velan gum, washed it, and Dry at 40°C and pulverize to obtain carboxyethyl welan gum. The product was dissolved in 400mL of 2wt% KCl solution, dissolved within 90min, and the degree of substitution of the product was 1.72.

Embodiment 2

[0026] In a three-necked flask, take Welan gum and dissolve it in water to form an aqueous solution with a concentration of 0.004mol / L, and stir it at a speed of 540rpm to fully dissolve it; in the solution prepared by 3-chloropropionic acid and potassium hydroxide, Wherein, the concentration of 3-chloropropionic acid is 0.016mol / L, the concentration of potassium hydroxide is 0.012mol / L, and the molar ratio of controlling Welan gum: 3-chloropropionic acid is 1:3; Add the solution of 3-chloropropionic acid and potassium hydroxide dropwise at a constant speed; react at normal pressure, 75°C and stirring for 5 hours, collect the reaction solution, pour it into absolute ethanol to precipitate carboxyethyl Velan gum, Wash, dry at 45°C, and pulverize to obtain carboxyethyl welan gum. The product was dissolved in 400mL of 2wt% KCl solution, dissolved within 30min, and the degree of substitution of the product was 0.58.

Embodiment 3

[0028] In a three-necked flask, dissolve Welan gum in water to form an aqueous solution with a concentration of 0.01mol / L, and stir it at a speed of 550rpm to fully dissolve it; in the solution prepared by 3-chloropropionic acid and sodium hydroxide, Wherein, the concentration of 3-chloropropionic acid is 0.02mol / L, the concentration of sodium hydroxide is 0.02mol / L, and the molar ratio of controlling Welan gum: 3-chloropropionic acid is 1:5; Add the solution of 3-chloropropionic acid and sodium hydroxide dropwise at a constant speed; react at normal pressure, 80°C, and stir for 6 hours, collect the reaction solution, pour it into absolute ethanol to precipitate carboxyethyl Velan gum, Wash, dry at 50°C, and pulverize to obtain carboxyethyl welan gum. The product was dissolved in 400mL of 2wt% KCl solution, dissolved within 90min, and the degree of substitution of the product was 0.42.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com