Device and application method for depositing film on side wall of micro-channel plate by using pressure difference

A technology of microchannel plate and thin film, which is applied in the direction of metal material coating process, coating, solid-state chemical plating, etc., can solve the problem of high cost and achieve the effect of deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

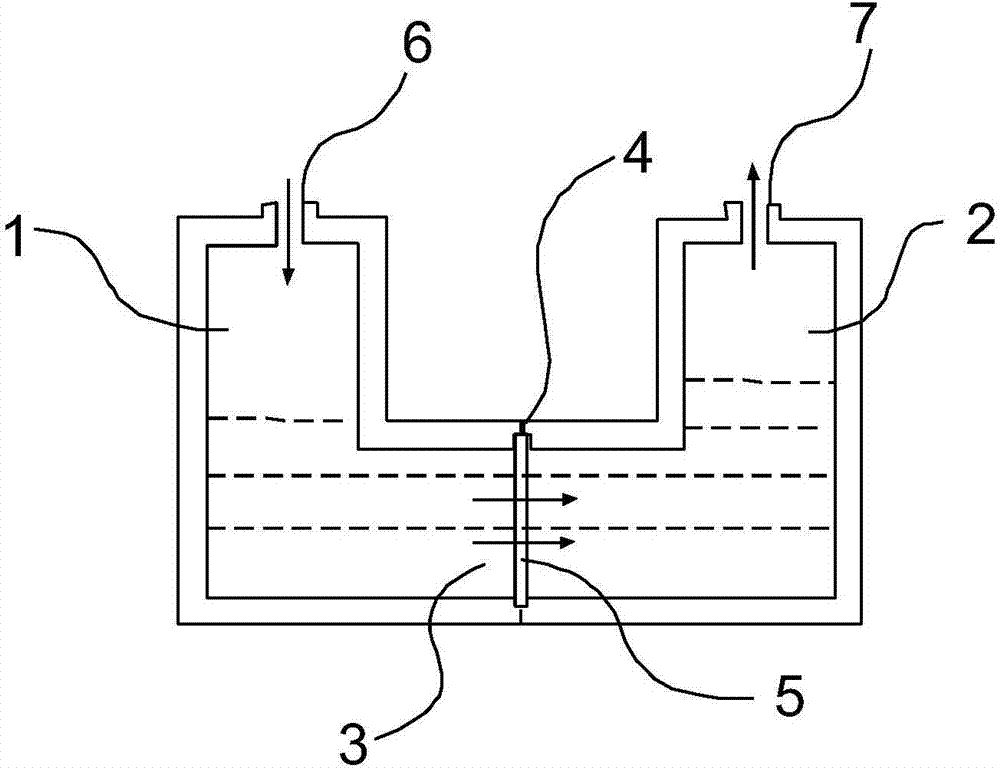

[0038] Embodiment 1: The horizontal placement structure of the positive pressure chamber and the negative pressure chamber

[0039] (1) Cut the microchannel plate 5 into figure 1 The shape and size of the cross-section of the middle card holder 4 at the bottom of the device match;

[0040] (2) Put the microchannel plate 5 into the tray 4 and fix it;

[0041] (3) Fill the sol liquid of the desired deposition film material from the positive pressure chamber 1;

[0042] (4) Inject compressed air from the air inlet 6, or use an air pump to extract air from the air outlet 7, or both, and use the pressure difference on both sides of the microchannel plate 5 to make the sol liquid pass through the microchannel plate from the positive pressure chamber 1 The inner pipe of 5 flows into the negative pressure chamber 2;

[0043] (5) Pour out the sol liquid, and take out the microchannel plate 5;

[0044] (6) Perform high-temperature treatment on the microchannel plate 5, so as to real...

Embodiment 2

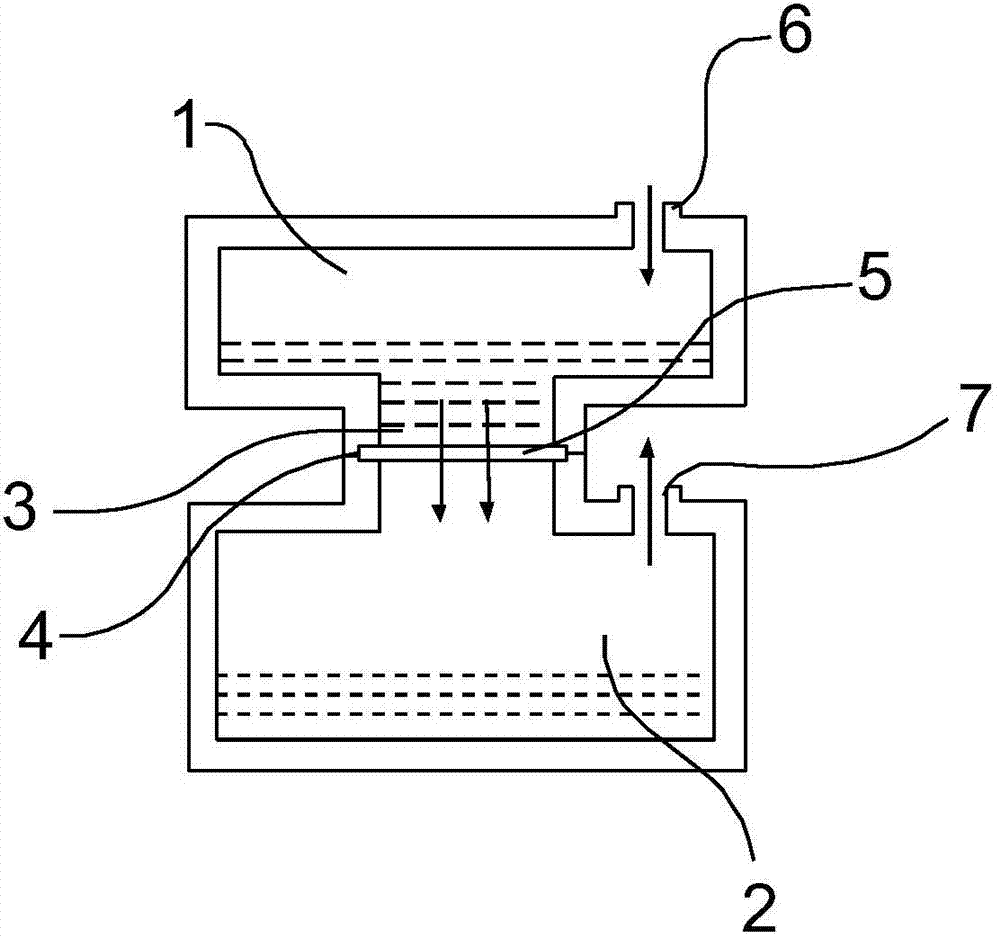

[0046] Embodiment 2: The positive pressure chamber and the negative pressure chamber are placed up and down

[0047] (1) Cut the microchannel plate 5 into figure 2 The shape and size of the cross-section of the middle card holder 4 in the device match;

[0048] (2) Put the microchannel plate 5 into the tray 4 and fix it;

[0049] (3) Fill the sol liquid of the desired deposition film material from the positive pressure chamber 1;

[0050] (4) Inject compressed air from the air inlet 6, or use an air pump to extract air from the air outlet 7, or both, and use the pressure difference on both sides of the microchannel plate 5 to make the sol liquid pass through the microchannel plate from the positive pressure chamber 1 The inner pipe of 5 flows into the negative pressure chamber 2;

[0051] (5) Pour out the sol liquid, and take out the microchannel plate 5;

[0052] (6) Perform high-temperature treatment on the microchannel plate 5, so as to realize the deposition of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com