Preparation method of non-fluorescence regenerated environmentally friendly short fiber

A short fiber, non-fluorescent technology, applied in the chemical characteristics of fibers, melt spinning, rayon manufacturing, etc., can solve problems such as harm to human health and environmental pollution, and achieve high stability, oil resource conservation, and long-term stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

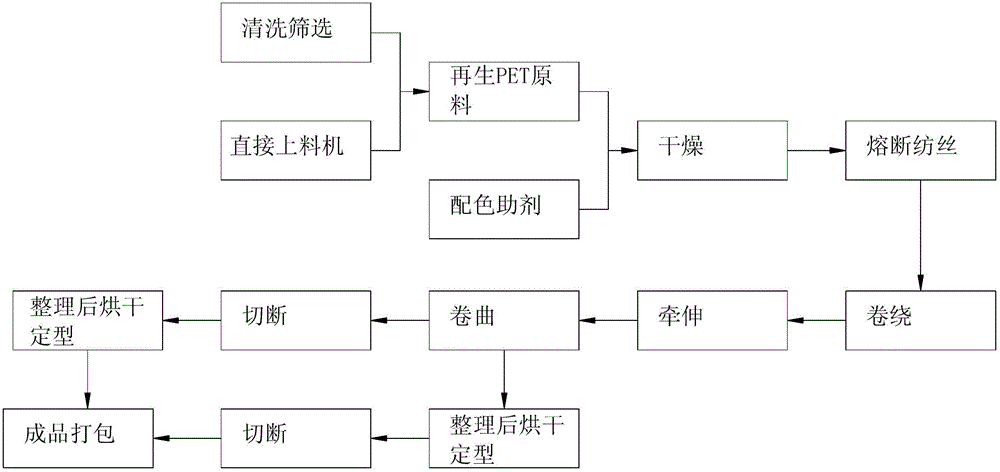

[0011] Embodiment 1: refer to figure 1 . A method for preparing non-fluorescent regenerated environmentally friendly short fibers, the main steps of which include: selecting regenerated PET raw materials containing color matching additives, drying-melt spinning-cooling and winding-drawing-curling-cutting, finishing, drying and shaping or After sorting, drying and shaping, cut off—package, among which

[0012] a) The color matching aid is formulated from ultraviolet shielding agent, brightener, light stabilizer and toner, the mass percentage of recycled PET raw materials is 98.9% to 99.79%, and the mass percentage of ultraviolet shielding agent is 0.1% to 0.5% , the mass percentage of the brightener is 0.05% to 0.3%, the mass percentage of the light stabilizer is 0.05% to 0.2%, and the mass percentage of the toner is 0.01% to 0.1%;

[0013] b) In the drying process: the drying vacuum degree of the recycled PET raw material is -0.1MPa, the drying temperature is 170 ° C ~ 200 °...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com