A crack-damage controllable frp grid reinforced high durability reinforced concrete column structure

A reinforced concrete column and concrete technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of low axial stiffness and large lateral deflection of FRP pipes, and achieve the effect of improving bearing capacity, improving bearing capacity and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the present invention is described in detail:

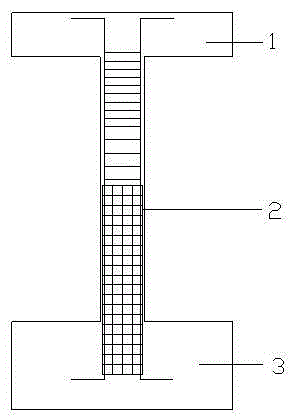

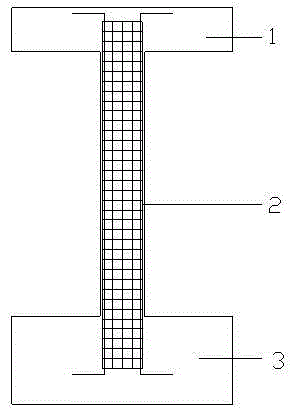

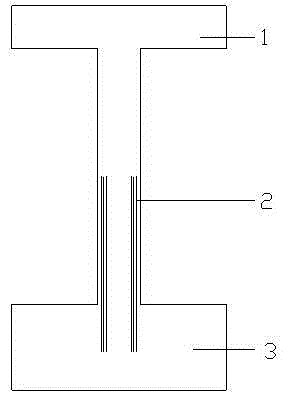

[0036] like figure 1 , figure 2 As shown, the crack and damage controllable FRP grid reinforced high-durability reinforced concrete column structure of the present invention includes a column bottom 1, a column body 2 and an upper end beam 3, wherein the column body 2 is composed of concrete 23 and a skeleton arranged inside the concrete 23 , the skeleton includes a steel skeleton and at least one layer of FRP mesh 24, the lower end of the steel skeleton and FRP mesh 24 goes deep into the column body 1, the height of the FRP mesh is greater than the height of the plastic hinge area of the column body, and the height of the plastic hinge area of the column, according to China For Lp stipulated in the Rules for Seismic Design of Highway Bridges (JTG / TB02-01-2008), the smaller value of the calculation result of the following formula is taken:

[0037] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com