Electromechanical hydraulic hybrid power transmission device for cutting part of coal mining heading machine

A composite power and transmission technology, applied in transmission, fluid transmission, transmission parts, etc., can solve the problems of low operation efficiency, power transmission system can only decelerate, and operation is inconvenient, and achieve the effect of protection and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

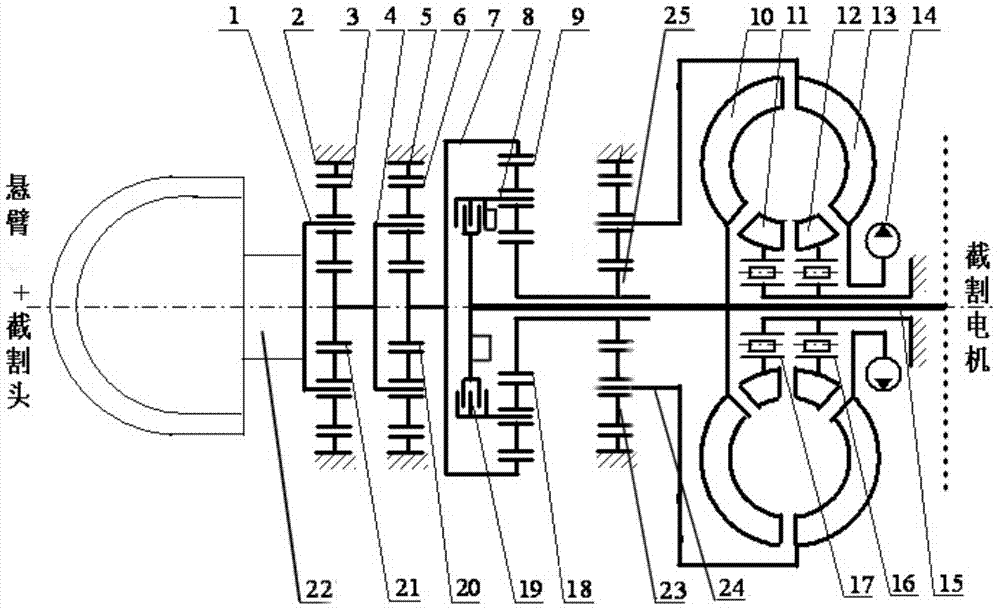

[0039] like figure 1 As shown, an electromechanical-hydraulic compound power transmission device for the cutting part of a roadheader for coal mining, including an input shaft 15, a hydraulic torque converter, a first planetary row, a clutch 19, a second planetary row, a third planetary row and an adjusting Speed gear set, wherein: the first planetary row is composed of the first planetary row sun gear 18, the first planetary row planetary gear 9, the first planetary row carrier 8 and the first planetary row ring gear 7; the second planetary row is composed of the first planetary row The second planetary row sun gear 20, the second planetary row planetary gear 6, the second planetary row carrier 4 and the second planetary row ring gear 5; the third planetary row is composed of the third planetary row sun gear 21, the third planetary row planet wheel 3, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com