Process-compatible decoupling capacitor and method for making the same

A technology for decoupling capacitors and capacitor electrodes, which is applied in the fields of capacitors, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., and can solve the problems that decoupling capacitors cannot completely meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be understood that the following disclosure provides many different embodiments and examples for implementing the different features of the invention. Specific examples of components and arrangements are described below to simplify the present disclosure. Of course, these are examples only and not intended to be limiting. Furthermore, in the following description the first part is formed over or on the second part includes an embodiment in which the first and second parts are formed to be in direct contact, and may also include an embodiment in which a part is formed interposed between the first and second parts. An embodiment of an additional component so that the first and second components are not in direct contact. Various components in the drawings may be arbitrarily drawn in different scales for simplicity and clarity.

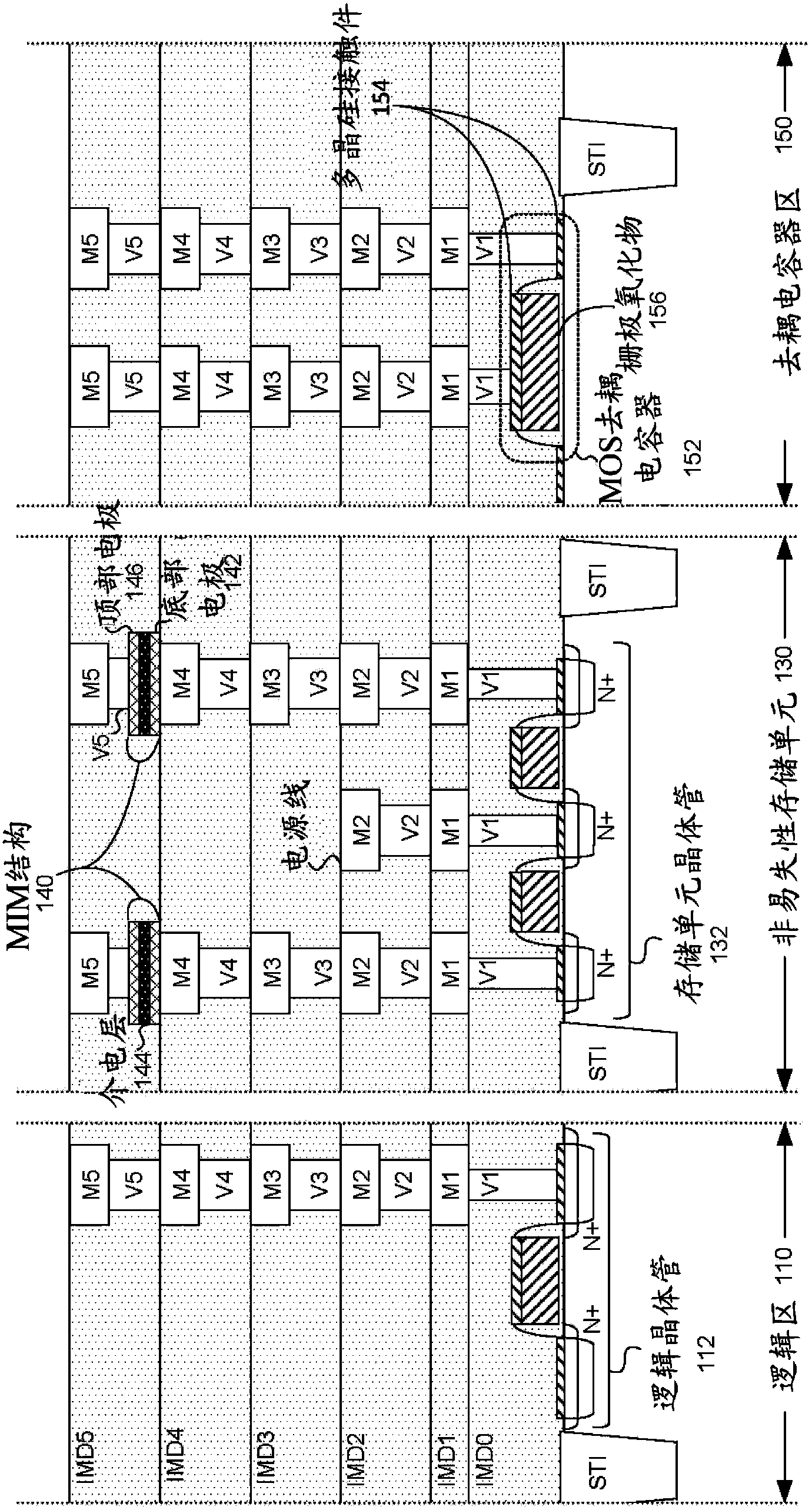

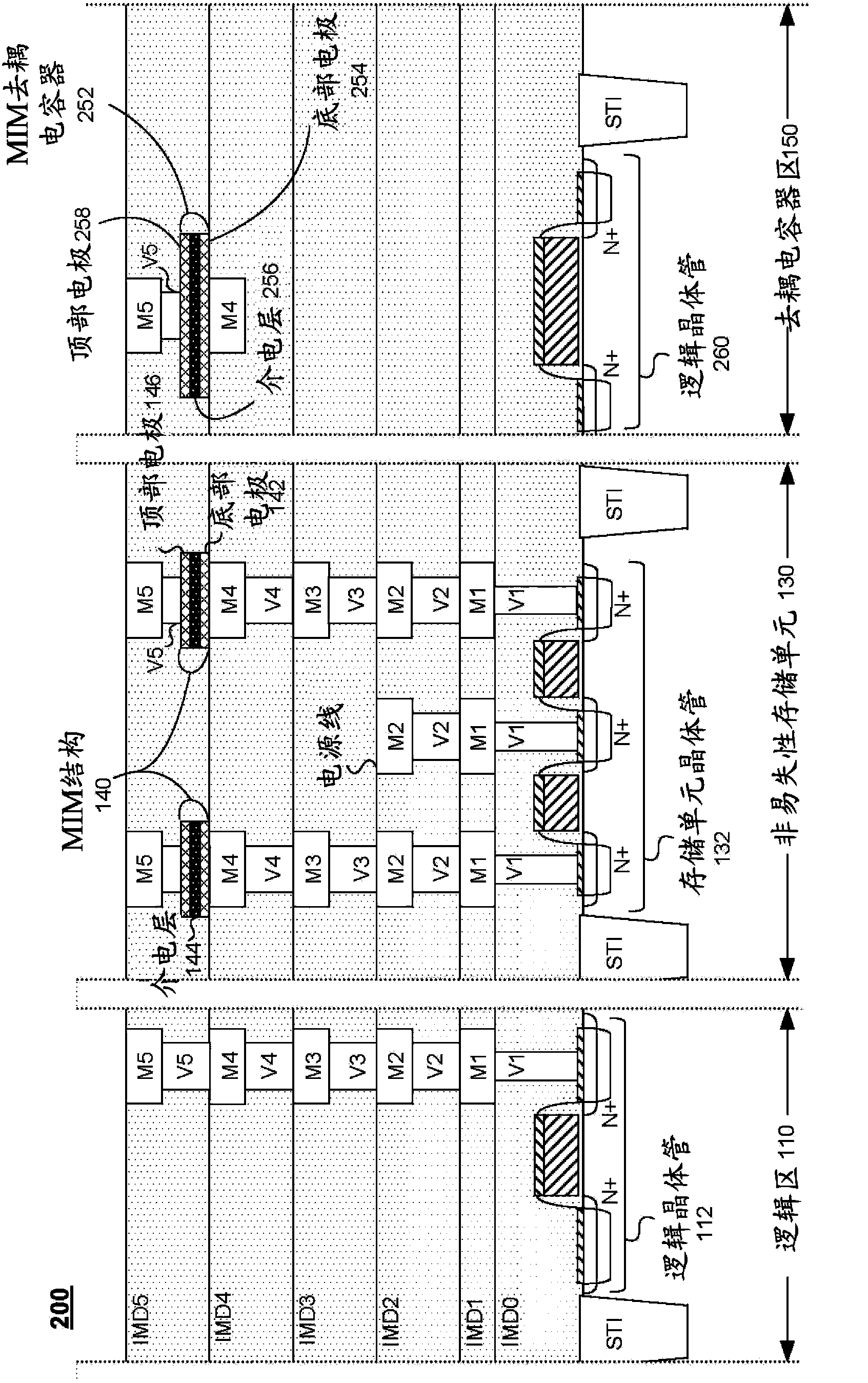

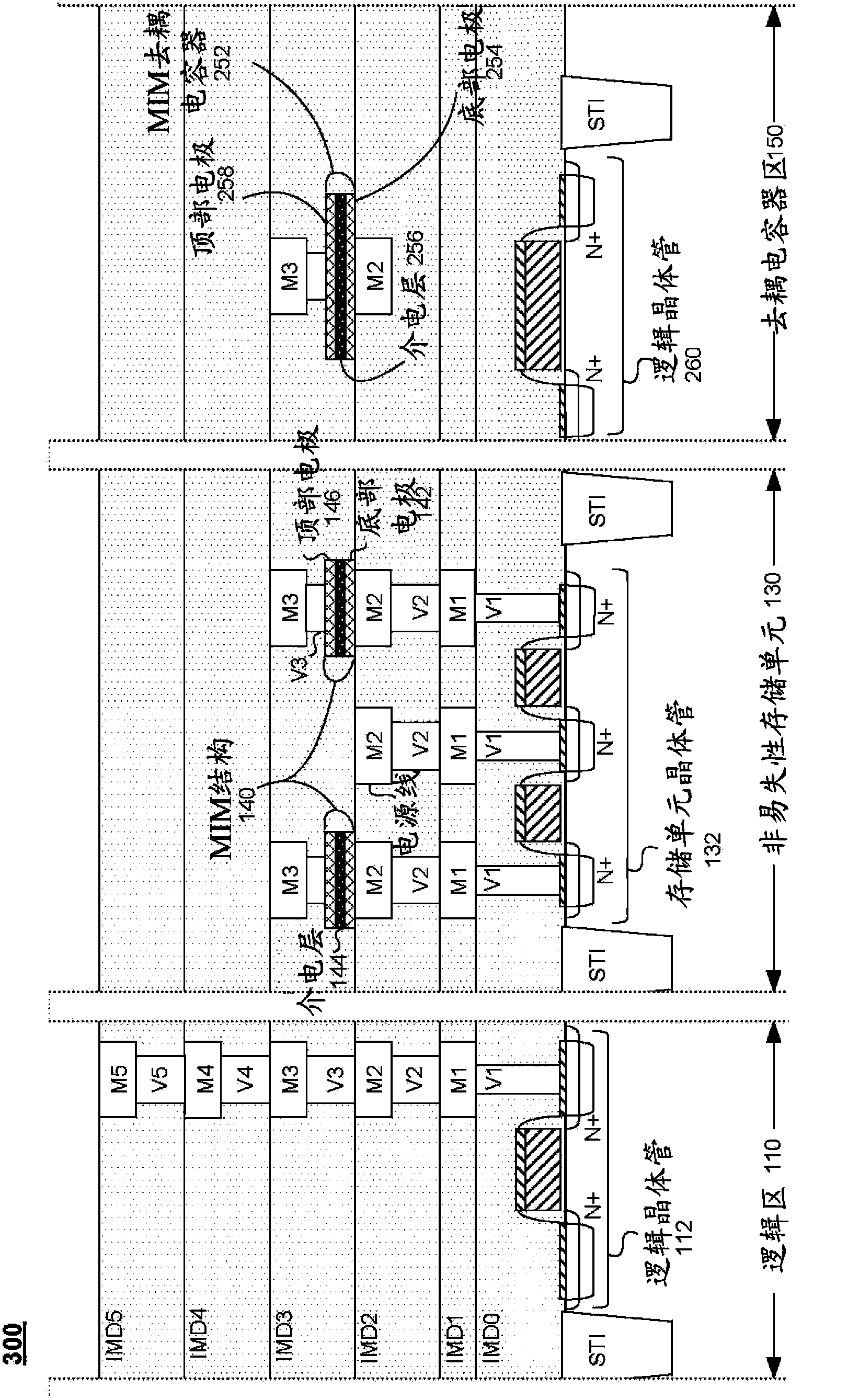

[0035] figure 1 A system-on-chip (SOC) 100 is shown, which may include multiple functional areas fabricated on a single substrate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com