Static random access memory in embedded germanium silicon process and write-in redundancy improving method

An embedded germanium-silicon, static random technology, used in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve the problems of small equivalent resistance and low write redundancy, and achieve increased equivalent resistance, improved hole mobility, and improved write redundancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

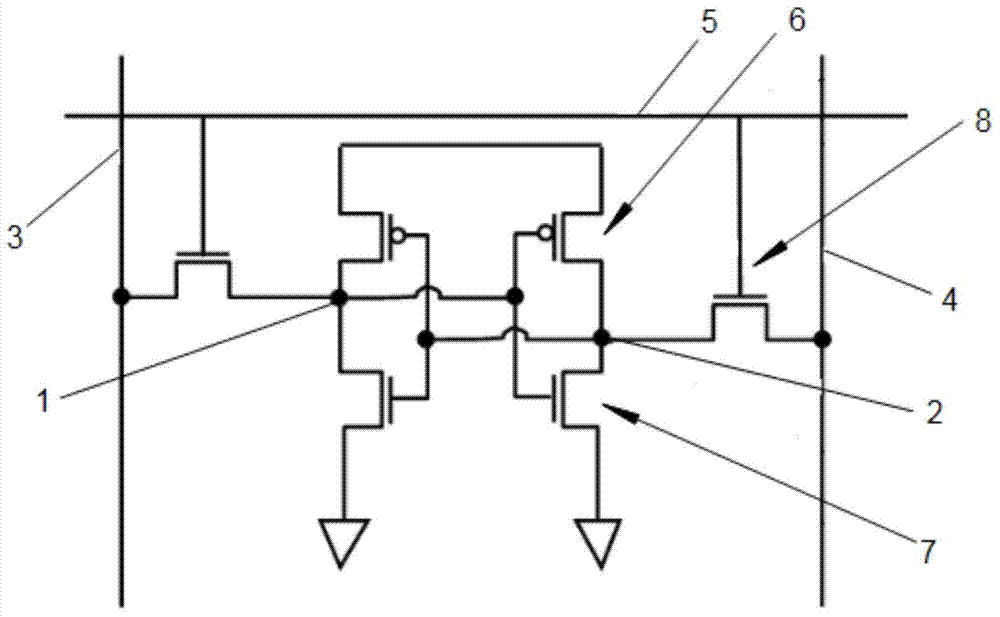

[0022] see figure 1 , figure 1 Shown is a schematic diagram of an equivalent circuit for writing SRAM in the embedded silicon germanium process of the present invention. Write margin (Write Margin) is an important parameter to measure the writing performance of SRAM cells in the embedded SiGe process. In the equivalent circuit for writing SRAM in the embedded silicon germanium process, it is assumed that the first node 1 stores data at a low potential (that is, the stored data is "0"), and the second node 2 stores data It is a high potential (that is, the stored data is "1"), non-limiting enumeration, for example, writing a high potential to the first node 1, writing a low potential to the second node 2, before the writing action, The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com