A self cleaning gas-liquid separator for serial or parallel collection of liquid fractions

A technology for collecting containers and liquids, which is used in solid adsorbent liquid separation, separation methods, material separation, etc., and can solve problems such as changes in mobile phase and discharge time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

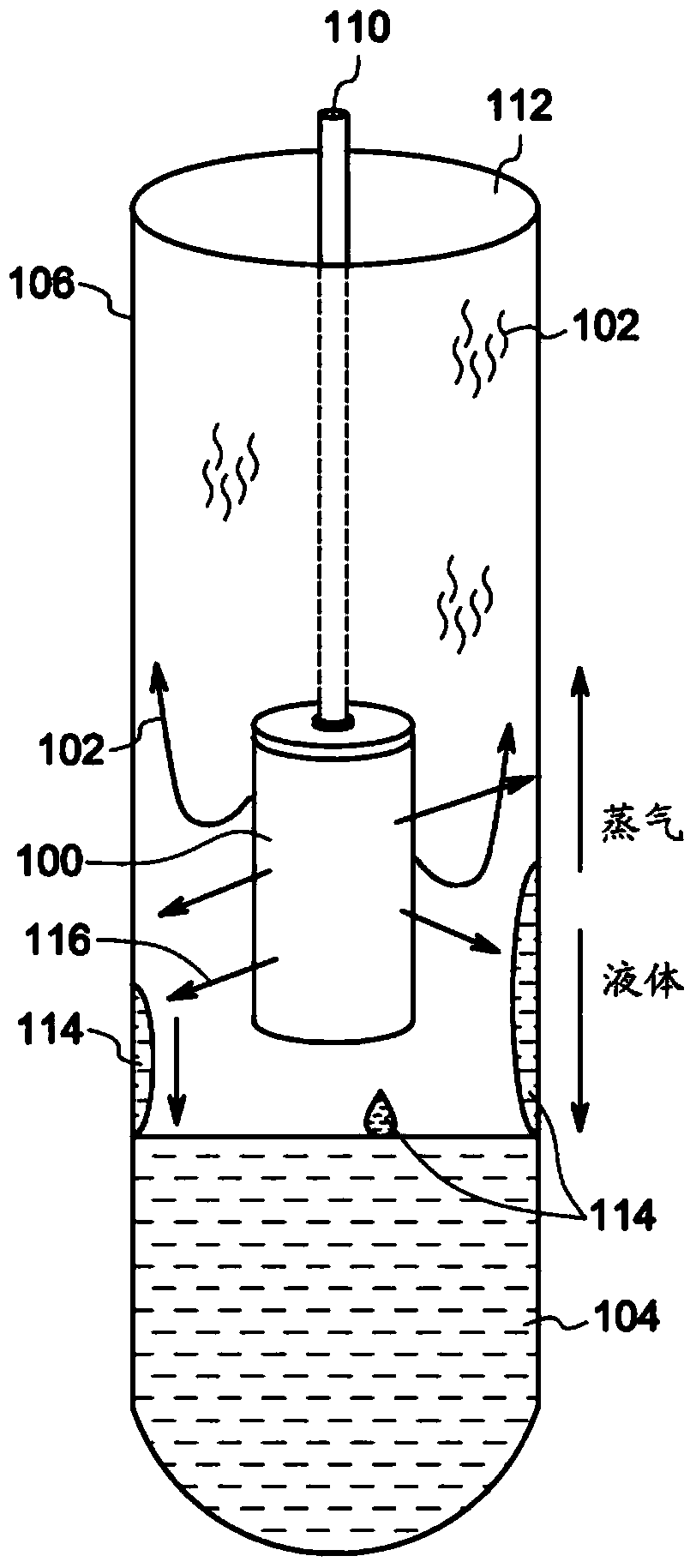

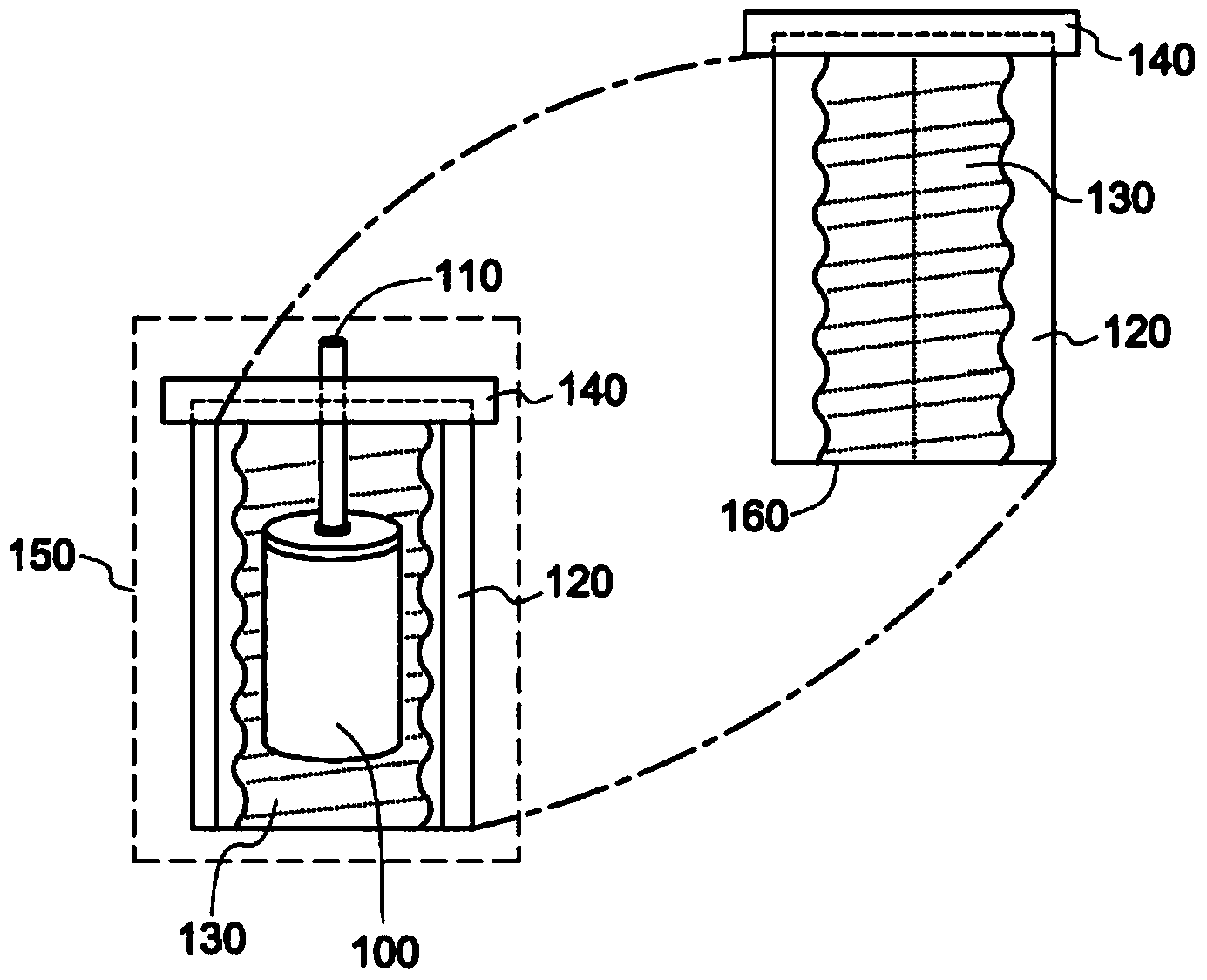

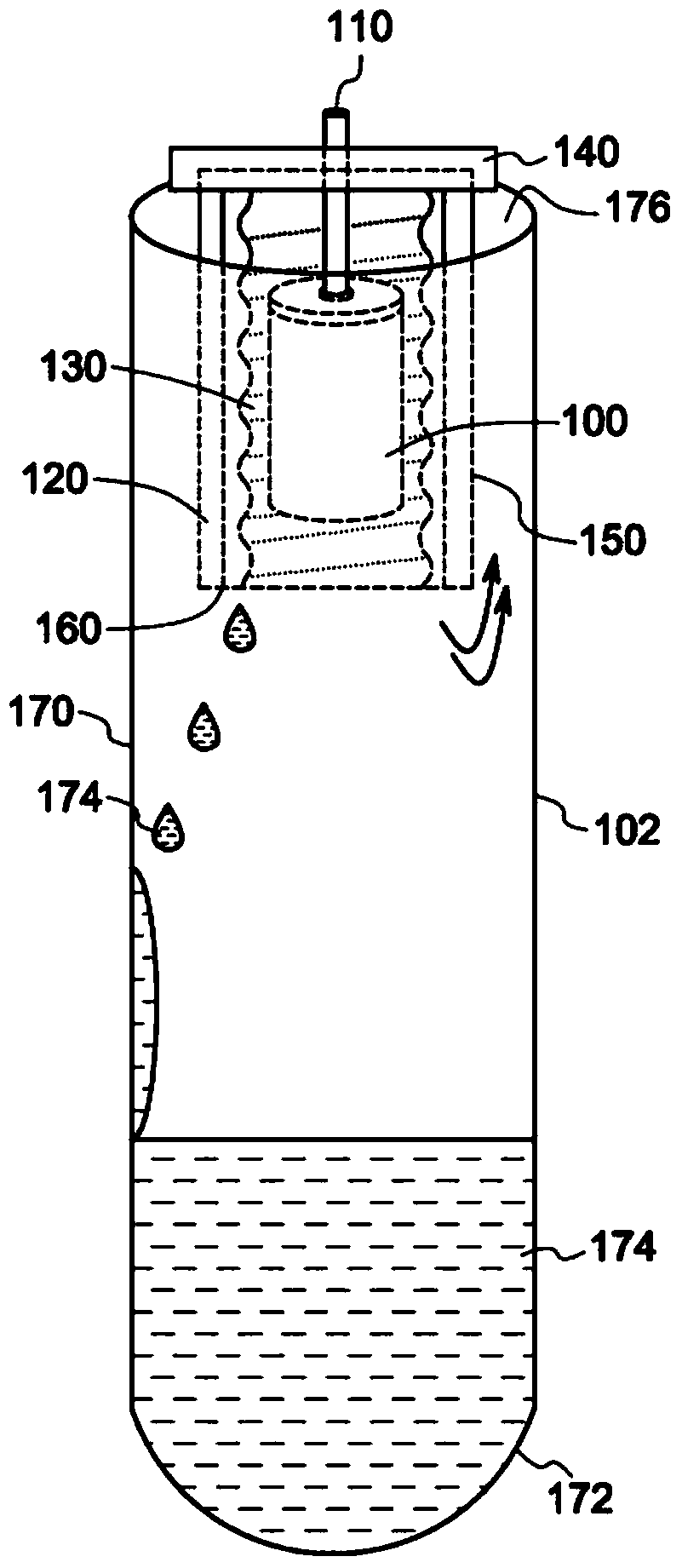

Method used

Image

Examples

other Embodiment approach

[0046] Other embodiments provide additional rinse capability via a syringe pump 550 connected by a flow path to the syringe valve 560 and circuit 570 . In its normal state, circuit 570 is connected between syringe pump 550 and waste 548 via flow path 546, wherein circuit 570 may be filled with a suitable wash solvent. When the end of the peak is detected, valve 560 is switched to pass the contents of circuit 570 to separator assembly 150 as a flood wash step. This behavior should adequately limit any carryover from prior samples. After a short time, the valve 560 is switched back and the circuit is filled again. It will be appreciated that the pump 550 could be replaced by a variety of other pump types, or even a pressurized wash solvent reservoir and solenoid valve to complete loop filling.

[0047] Figure 7 [0009] Another embodiment in ® includes an active discharge pumping system, which is the subject of a separate pending patent application assigned to the same assigne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com