Method for processing tin refining sulfur slag

A treatment method and sulfur slag technology, applied in the direction of improving process efficiency, etc., can solve the problems of many process flows and large mechanical loss of tin, etc., and achieve the effect of simple process, convenient operation, safe and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

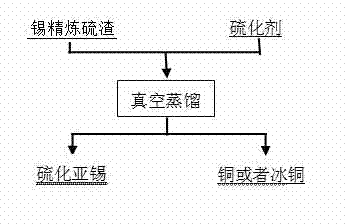

[0011] Such as figure 1 As shown, the treatment method of the tin refining sulfur slag, the specific steps are as follows: First, mix 100g of tin refining sulfur slag and vulcanizing agent according to the Sn:S molar ratio of 1:1 to obtain a mixed material, and then put the mixed material into a vacuum furnace In the reaction time, the pressure is 1Pa and the temperature is 700°C for 50 minutes to prepare copper or matte and solid stannous sulfide on the condenser.

[0012] Among them, the tin refining sulfur slag comes from the tin refining process of sulfur addition and copper removal, including the following components in mass percentage: Sn40%, Cu20%, S10%; the vulcanizing agent is sulfur.

[0013] Finally, the quality of volatile matter is 64.7g, carries out phase analysis to this volatile matter, and main component is stannous sulfide, and tin content is 39.28g in the volatile matter through chemical analysis and calculation, and tin direct recovery rate is 98.2%, and co...

Embodiment 2

[0015] Such as figure 1 As shown, the treatment method of the tin refining sulfur slag, the specific steps are as follows: First, mix 100g of tin refining sulfur slag and vulcanizing agent according to the Sn:S molar ratio of 1:2.5 to obtain a mixed material, and then put the mixed material into a vacuum furnace Within the reaction time of 1min at a pressure of 100Pa and a temperature of 1200°C, copper or matte and solid stannous sulfide on the condenser can be prepared.

[0016] Among them, the sulfur slag from tin refining comes from the tin refining sulfur addition and copper removal process, including the following components in mass percentage: Sn80%, Cu10%, S5%; the vulcanizing agent is pyrite, and pyrite contains the following components in mass percentage : Fe46.67%, S53.33%.

[0017] Finally, the quality of volatile matter is 93.6g, carries out phase analysis to this volatile matter, and main component is stannous sulfide, and tin content is 78.8g in the volatile mat...

Embodiment 3

[0019] Such as figure 1 As shown, the treatment method of the tin refining sulfur slag, the specific steps are as follows: First, mix 100g of tin refining sulfur slag and vulcanizing agent according to the Sn:S molar ratio of 1:1.5 to obtain a mixed material, and then put the mixed material into a vacuum furnace In the reaction time, the pressure is 50Pa and the temperature is 1000°C for 30 minutes to prepare copper or matte and solid stannous sulfide on the condenser.

[0020] Among them, the tin refining sulfur slag comes from the process of adding sulfur to copper and removing copper from tin refining, and includes the following components in mass percentage: Sn60%, Cu14%, S7%; the vulcanizing agent is sulfur.

[0021] Finally, the quality of volatile matter is 75.8g, carries out phase analysis to this volatile matter, and main component is stannous sulfide, and tin content is 58.98g in the volatile matter through chemical analysis and calculation, and tin direct recovery r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com