Method for smelting ferro-nickel through smelting reduction of laterite-nickel ore

A technology of laterite nickel ore and nickel-iron alloy, applied in the field of ferroalloy, can solve the problem of high energy consumption, achieve the effects of improving economic benefits, realizing efficient utilization, and shortening process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

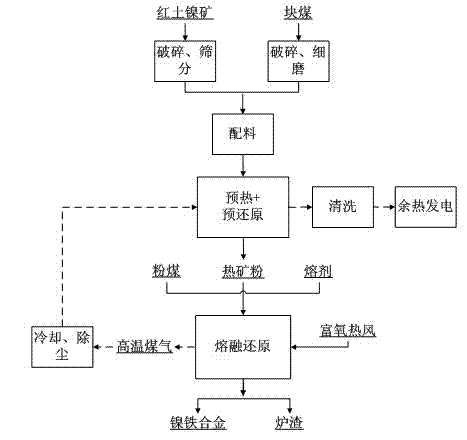

[0022] like figure 1 Shown, the method for smelting nickel-iron alloy by smelting reduction of this laterite nickel ore, its specific steps are as follows:

[0023] (1) First, mix the laterite nickel ore crushed to a particle size of 5mm and lump coal with a particle size of 1mm according to a mass ratio of 40:1 to obtain a mixture, and then add the mixture to the preheater. Dry and pre-reduce for 2 hours to obtain hot ore powder. The laterite nickel ore is silicon-magnesium type laterite nickel ore. The content of Ni in the laterite nickel ore is 0.8wt.%, and the content of Fe is 8wt.%. The preheater has multi-level functions Cyclone preheater;

[0024] (2) After mixing the hot ore powder, pulverized coal and flux evenly, smelt reduction for 3 hours under the condition of bubbling oxygen-enriched hot air at a temperature of 1400°C. After the reaction is completed, nickel-iron alloy and slag can be obtained. The pulverized coal contains The carbon content is 80wt.%. The amou...

Embodiment 2

[0028] like figure 1 Shown, the method for smelting nickel-iron alloy by smelting reduction of this laterite nickel ore, its specific steps are as follows:

[0029] (1) First, mix the laterite nickel ore crushed to a particle size of 20mm and lump coal with a particle size of 10mm according to a mass ratio of 50:2 to obtain a mixture, and then add the mixture to the preheater, at a temperature of 1100°C Dry and pre-reduce for 5 hours to obtain hot ore powder, wherein the laterite nickel ore is silicon-magnesium type laterite nickel ore, the content of Ni in the laterite nickel ore is 2wt.%, and the content of Fe is 15wt.%. Chemical bed;

[0030] (2) After mixing the hot ore powder, pulverized coal and flux evenly, smelt reduction for 8 hours under the condition of bubbling oxygen-enriched hot air at a temperature of 1600°C. After the reaction is completed, nickel-iron alloy and slag can be obtained. The pulverized coal contains The carbon content is more than 70wt.%. The amo...

Embodiment 3

[0034] like figure 1 Shown, the method for smelting nickel-iron alloy by smelting reduction of this laterite nickel ore, its specific steps are as follows:

[0035] (1) First, mix the laterite nickel ore crushed to a particle size of 15mm and the lump coal with a particle size of 5mm according to the mass ratio of 45:1 to obtain a mixture, and then add the mixture to the preheater. Drying and pre-reduction for 4 hours to obtain hot ore powder, wherein the laterite nickel ore is a silicon-magnesium type laterite nickel ore, the content of Ni in the laterite nickel ore is 1wt.%, and the content of Fe is 10wt.%. The preheater is a cyclone with multi-level functions Preheater;

[0036](2) After mixing the hot ore powder, pulverized coal and flux evenly, smelt reduction for 6 hours under the condition of bubbling oxygen-enriched hot air at a temperature of 1500°C. After the reaction is completed, nickel-iron alloy and slag can be obtained. The pulverized coal contains The amount ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com