A method for producing nickel-iron alloy by two-step reduction of laterite nickel ore by natural gas-electric furnace melting

A technology of laterite nickel ore and nickel-iron alloy is applied in the field of non-ferrous metal metallurgy, which can solve the problems of insufficient utilization of tail gas, serious heat loss and high production cost, and achieve the effects of perfecting smelting process, improving nickel grade and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

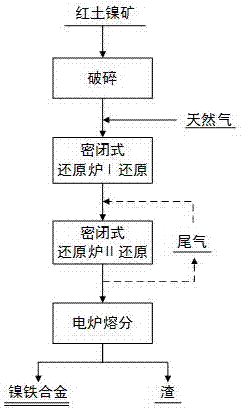

[0023] like figure 1 As shown, the method for producing nickel-iron alloy by reducing laterite nickel ore in two steps with natural gas-electric furnace melting, crushing laterite nickel ore, and then introducing natural gas as a reducing agent to carry out the first step reduction in the first closed reduction furnace to obtain Reductant and reducing tail gas, add the reducing substance and reducing tail gas into the second closed reduction furnace for the second step reduction to obtain the reduction product and tail gas, the tail gas is returned to the second closed reduction furnace, and the reduction product is processed by the second closed reduction furnace. The nickel-iron alloy and slag are obtained by melting and fractionating in the electric furnace. The whole production process mentioned above is a continuous process, with less heat loss and high energy utilization rate.

[0024] Specific steps are as follows:

[0025] (1) First, the laterite nickel ore (including...

Embodiment 2

[0031] like figure 1 As shown, the method for producing nickel-iron alloy by reducing laterite nickel ore in two steps with natural gas-electric furnace melting, crushing laterite nickel ore, and then introducing natural gas as a reducing agent to carry out the first step reduction in the first closed reduction furnace to obtain Reductant and reducing tail gas, add the reducing substance and reducing tail gas into the second closed reduction furnace for the second step reduction to obtain the reduction product and tail gas, the tail gas is returned to the second closed reduction furnace, and the reduction product is processed by the second closed reduction furnace. The nickel-iron alloy and slag are obtained by melting and fractionating in the electric furnace. The whole production process mentioned above is a continuous process, with less heat loss and high energy utilization rate.

[0032] Specific steps are as follows:

[0033] (1) First, the laterite nickel ore (including...

Embodiment 3

[0039] like figure 1 As shown, the method for producing nickel-iron alloy by reducing laterite nickel ore in two steps with natural gas-electric furnace melting, crushing laterite nickel ore, and then introducing natural gas as a reducing agent to carry out the first step reduction in the first closed reduction furnace to obtain Reductant and reducing tail gas, add the reducing substance and reducing tail gas into the second closed reduction furnace for the second step reduction to obtain the reduction product and tail gas, the tail gas is returned to the second closed reduction furnace, and the reduction product is processed by the second closed reduction furnace. The nickel-iron alloy and slag are obtained by melting and fractionating in the electric furnace. The whole production process mentioned above is a continuous process, with less heat loss and high energy utilization rate.

[0040] Specific steps are as follows:

[0041](1) First, the laterite nickel ore (including ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com