Wood structure floor

A technology for wood structure and floor slab, applied in the direction of floor slab, building components, building structure, etc., can solve the problem of lack of mature technology, and achieve the effect of preventing cracking, satisfying the decorative style and preventing wood cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

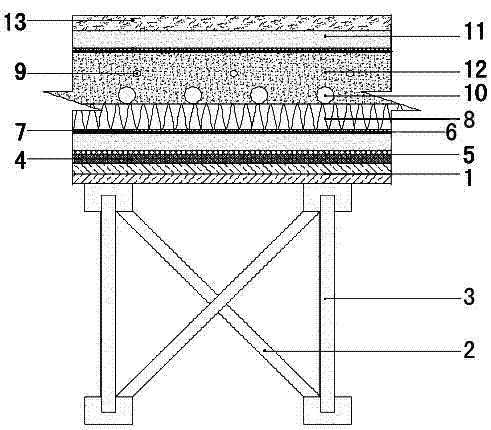

[0018] Example: such as figure 1 As shown, a wooden structure floor slab includes an I-shaped grille 3 and a structural layer.

[0019] A scissors brace 2 is connected between each pair of I-shaped grids 3, and the scissors brace 2 is X-shaped, and each piece of scissors brace is connected with the upper end of one I-shaped grille and the lower end of another I-shaped grille. The I-shaped grille 3 with a spacing of 300mm and the scissor brace 2 with a spacing of 600mm play the role of bearing and dispersing stress. The scissors brace 2 and the I-shaped grille 3 should be imported wood, and anti-corrosion and anti-moth treatment should be carried out according to the requirements of the wood structure. The scissors brace 2 should just touch the upper and lower ends of the I-shaped grille 3 to ensure the firmness of the floor.

[0020] The structural layer is set on the I-shaped grid 3 of the load-bearing base, followed by the wooden structure layer 1, the cement board layer 4,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com