Reciprocating pump with fluid source power control switching single plunger

A power control and fluid source technology, which is applied in the field of reciprocating pumps, can solve the problems of fluid flow switching device failure, spring fatigue limit, spring fatigue, etc., and achieve the effect of simple long life, long service life and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

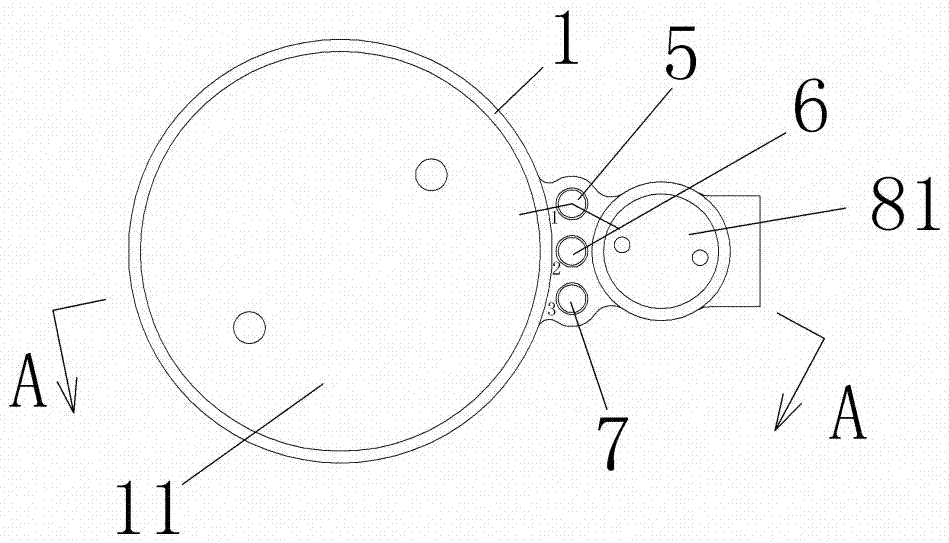

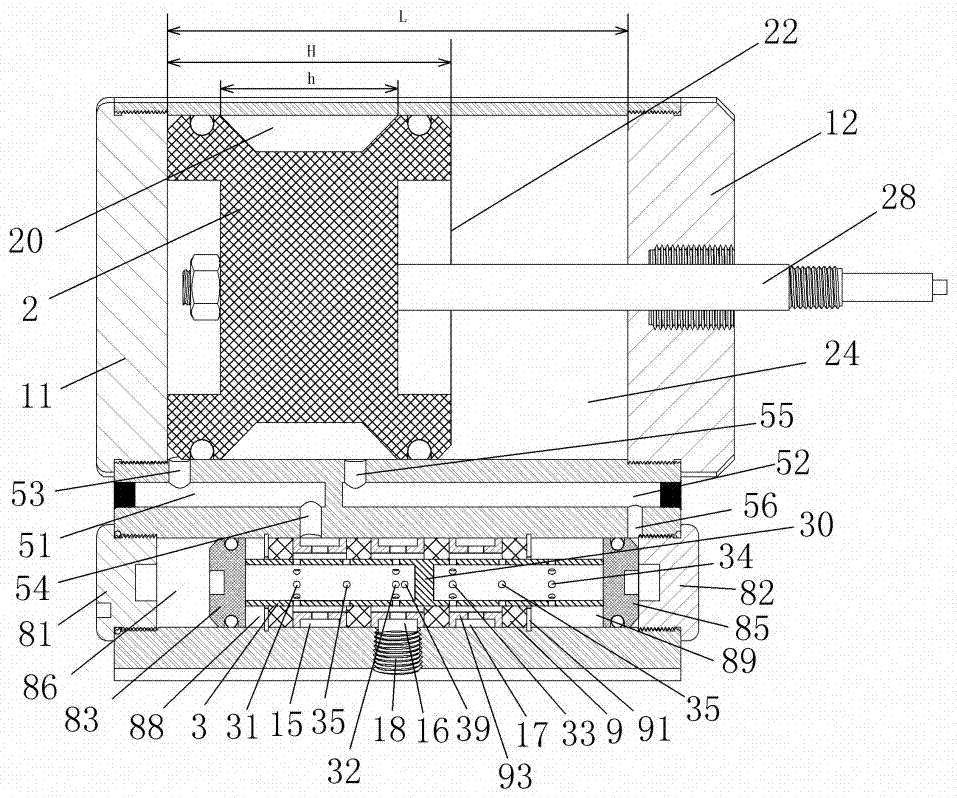

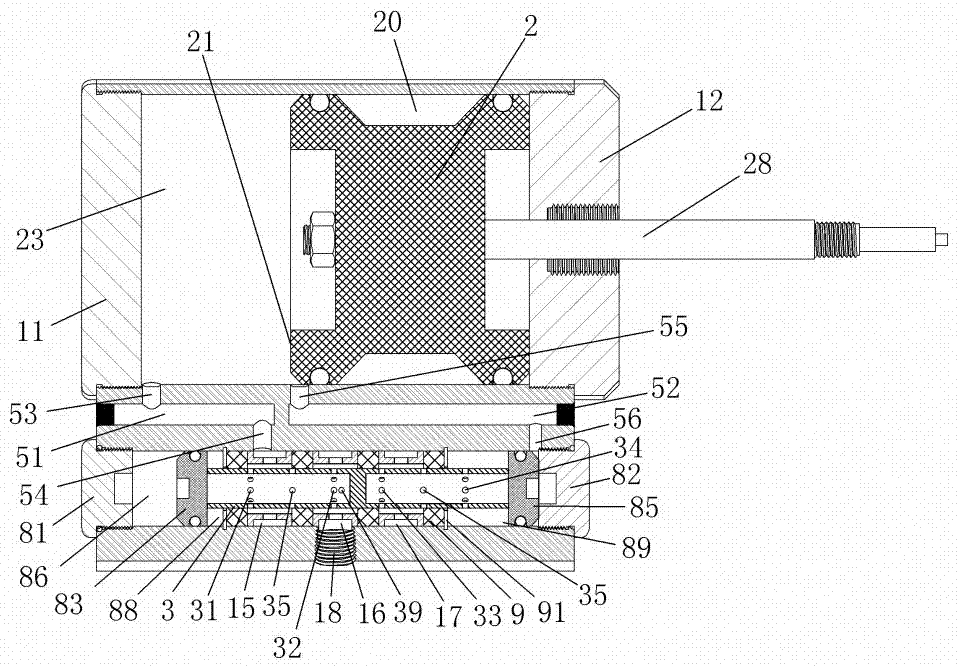

[0022] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, it is a specific embodiment of the reciprocating pump with fluid source power control switching single plunger according to the present invention. The fluid source power control switching single plunger reciprocating pump includes a pump body cavity for sealing with the pump piston. The pump body 1. The pump piston 2, which cooperates with the inner edge of the pump body cavity and divides the pump body cavity into the first pump body cavity 23 and the second pump body cavity 24. The first and second ends of the pump body are combined and sealed with the pump body. The first pump body cover 11 and the second pump body cover 12 are provided with a piston rod through hole at the center of the first or second pump body cover of the pump body. The sides of the cavity pump piston opposite to the first pump body cover are the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com